Each car owner is sooner or later faced with such a phenomenon as rust that may occur in any part of the car body. Even small damage to the coating is enough for corrosion to start spreading, capturing all new places. Significant corrosion damage to the body can entail expensive repairs, therefore it is necessary to eliminate the problem immediately upon its occurrence. You can do this with a special means - rust converter. About this further in the article.

Content

Rust converter, purpose

Corrosion of metal sections of the car is an absolutely natural phenomenon. It occurs in places of damage to the protective coating when the metal is contaminated with water or air. Regular temperature differences also have an impact on the emergence and growth of corrosion. Unfortunately, today there are no such technologies that could completely prevent the occurrence of corrosion, but there are funds and they are successfully fighting with rust and slow down its distribution.

The rust converter belongs to them. Of course, he does not allow a hundred percent guarantee of corrosion prevention, but in a state for a certain time to protect the car body from the harmful effects of the external environment. The processing of the vehicle by the rust converter is able to neutralize the existing foci and prevent their expansion. However, before purchasing funds, you must examine information about it before purchasing the funds, in particular, you will receive answers to the following questions - what are the types of converters, what the principle of their action, and what safety measures need to be observed during their application of the car.

The composition of the rust converter and the principle of operation

Rust transducers provide neutralization of corrosion foci by influencing it elements that are part of the tool. Depending on the variety of funds, converters may consist of ingredients different from each other, but the main active substance is usually the other acid. The most common are products based on oxycarbonic and orthophosphoric acids. Acids can actively interact with rust compounds, thereby neutralizing their harmful effects, so they are often the basis of the converters.

The principle of operation of acid-based transducers is such - the chemical reactions with an acid convert iron oxides (rust compounds) into acid salts, which are chemically inactive, in the form of a peculiar plaque on the metal surface of the body, which is considered a conventional cloth.

There are also means created on the basis of zinc salts. When applying such a converter, zinc compounds create a protective film on a metal surface, which prevents the appearance of corrosion. The principle of operation on a zinc-based basis - as a result of applying a substance, the reaction of binding of zinc atoms with oxygen atoms is launched. As a result, we obtain a chemically inactive connection that looks like a film designed to protect the metal surface.

What are rust converters, how they are applied

With the help of the converter, you can remove rust foci from any section of the car body. For the convenience of applying it to different surfaces, transducers are produced in the form of pastes, sprays, emulsions and suspensions. The application method is chosen depending on the location of the focus of rust and consistency of the means. The substance can be applied using the brush, use the sprayer or simply drop the corrosion source with a sufficient amount of the converter.

Top 10 Best Rust Transducers

By purchasing a means to eliminate corrosion for the first time, many drivers are wondering - what to choose a converter? The auto chemical market represents a wide selection of various means, so the difficulty of the car owners is not surprising. It is advisable to choose one of the well-proven funds, depending on the purposes that the motorist wants to achieve.

- To remove rust from steel surfaces, "zincar" is perfect. This remedy can destroy corrosion and form a reliable protective film on the processed section.

- To remove small foci rust, use the Movil tool with the converter. Removes the existing rust and protects the metal surface from moisture exposure.

- The Hi-Gear converter line has proven itself among motorists. The tool retains its properties even in conditions of temperature differences and reliably protects damaged places from recurrence of corrosion.

- The "Kolchug" means is well suited for protection against rust on surfaces from ferrous metals. You can apply it to both foci corrosion and intact places for the appearance of a protective film.

- Sonax can cope with corrosion, removes its traces, and at the same time will serve as a primer for subsequent processing of the car body surface.

- The "SF-1" converter is designed to combat rust on galvanized and cast-iron surfaces, which has proven itself perfectly.

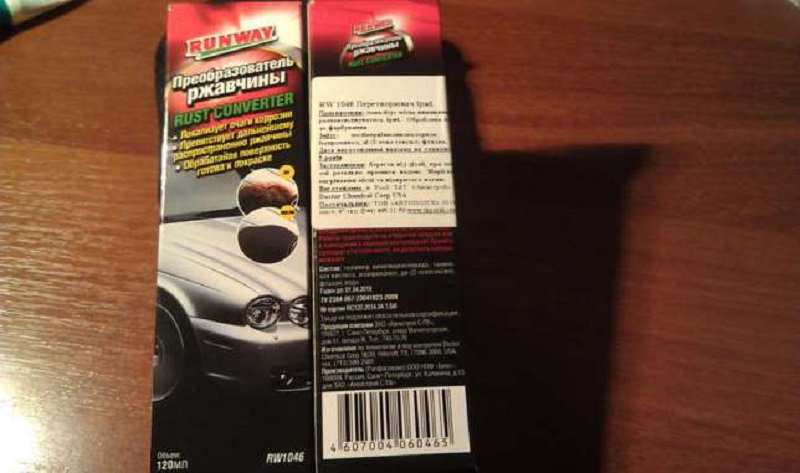

- Another converter with primer functions is the "Runway" tool, which will remove corrosion and fill out shallow cracks before treating the body.

- Means "Permatex" Specialists advise to work with fiberglass. During its application, the rust turns into a polymer coating.

- The rust converter "Bitumast" has the ability to restore iron oxides to the initial state and form a protective phosphate film.

- The "phosphomet" eliminates rust with galvanized, cast-iron, aluminum and steel surfaces, suitable for most types of LKM.

How to remove rust with a converter

Since different converters, although not strong, but still differ from each other, the procedure for using data of funds is better to learn from the instruction. However, you can select a number of moments that are mandatory for any type of converter:

- The thickness of the processed corrosion layer should be no more than 0.1 millimeters. The active components of the converter simply will not be able to overcome the large volume of rust.

- It is necessary only to process rust layers, which entered into the metal, the loose layer is perfectly eliminated with any abrasive material together with dirt and dust.

- If after processing the signs of corrosion remained, repeat the procedure, but before this clean the surface from the converter layer applied earlier.

Acid tools are easier to use. They must simply apply to the desired area and wait a certain amount of time provided by the instructions. After the expiration of a specific period, the flare, which appeared as a result of the reaction, is considered a brush, and the purified surface may be subjected to further processing.

The use of converters on a zinc-based basis is more labor and, moreover, has several nuances. When applied, the electroplating pair can be needed between the metal part of the body and zinc. As a rule, this use acb and electrodes for this.

Safety regulations when using rust converters

- Avoid a long stay in the room, which carries out the car processing by the converter, since the pairs of means are able to fall into the lungs when applied.

- Do not allow the substance to fall into open skin, since the means is very toxic. In addition, its composition contains active acids, so it is necessary to use overalls and other means of protection.

- Before working with an acid-based basis, it is recommended to test it on old and unnecessary details, since high acid activity is able to harm the bodies that are not damaged by corrosion.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments