The shock absorber is one of the main parts of the suspension of the vehicle. Its direct responsibility is mitigation and quenching, all shocks and oscillations coming on the car body from an uneven road cover. The shock absorber provides safety and increases the service life of the other vehicle suspension elements, and also creates comfort and convenience of passengers and the driver when traveling on a vehicle.

Content

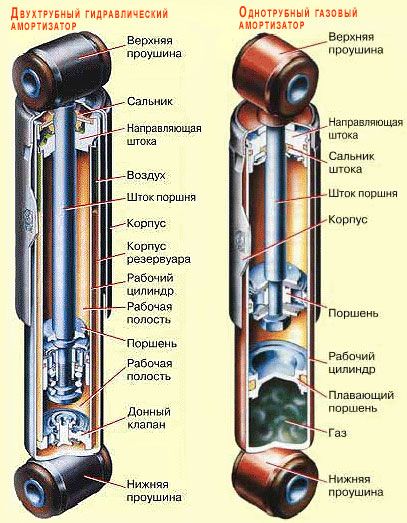

Device shock absorber

Car shock absorbers are 3 main species - this is gas, gas oil and oil.

To date, the first two types of shock absorbers are widespread, the oil occurs less frequently. If you go into structural features, then it will be more correct to divide the car shock absorbers into two types:

- One-tube shock absorbers - precisely to this type of shock absorbers is gas. Since the main working substance in this form of shock absorbers is directly gas. It has a cylindrical body which is horizontally divided into two parts "floating" dividing piston. The lower part of the single-tube shock absorber is filled with an oil or other shock absorbing liquid, and the upper gas under pressure. Inside, a high-strength chrome-plated rod with a valve system for a penny and compression is running inside in a compartment with shock absorbing liquid. Examination of loads occurs due to the movement of the "floating" dividing piston.

- Two-pipe shock absorbers - this type includes gas oil and oil shock absorbers. This type of shock absorbers has two cavities: one of them is a worker - this is a cylinder, another compensation is the case is the same tank. They are separated by a special compression valve located directly at the bottom of the shock absorber. The reservoir is filled by 50% of the working fluid. Due to the aback and compression in a two-pipe shock absorber, an effort appears, which is determined by special valves. The pen valve is located directly on the piston, and compression at the bottom.

Interesting! In fact, pure gas shock absorbers do not exist, in the gas shock absorber, as in gas oil, there is oil, only it does not have direct contact with the gas.

Both types of automotive shock absorbers have two mounts located at both ends. One mount is attached to the car body another directly to the elements of the suspension.

Oil shock absorber, why pump shock absorbers before installing

Pumping a two-pipe shock absorber is essentially preparing the shock absorber directly to operation. In the case of installing a non-pumped shock absorber, it will soon fail with a high proportion. This is a violation of its installation instructions and the warranty for this case does not apply.

The thing is that in the case of a not pumped shock absorber directly in the sleeve, the air remains, which leads to a failure in its work and quickly fail. This is due to the fact that during its transportation and storage in the warehouse, the shock-absorbing liquid and gas are moved.

To prevent malfunctions in its work, a two-pipe shock absorber before installing must be pumped at mandatory. Pumping the shock absorber serves as a guarantor of its long and high-quality work.

Pumping the shock absorber, by which rules is done pumping

There are three main, unshakable rules for pumping a two-pipe car shock absorber:

- Pumping a two-pipe shock absorber occurs in the stem position up;

- At the end of the shock absorber pumping, it is not allowed to turn it into any of the provisions. The shock absorber must remain up, up to the moment of its immediate installation;

- In compression, it should be borne in mind that it is extremely recommended to fully compress the shock absorber, as in some of the shock absorbers, the oil is merged with full compression. Usually there are special technological grooves for which and compression occurs on two-pipe shock absorbers. In case of their absence, compression is not communicated to the end of 2-3 millimeters.

For the behavior of the procedure for pumping a two-pipe shock absorber, there is no need for a tool and special equipment. Pumping the shock absorber is made purely with hands.

Oil shock absorbers, pumping before installation, step-by-step instruction

Having studied the basic rules for pumping a two-pipe shock absorber, you can proceed directly to this procedure:

- Initially, the shock absorber must be rotated so that its stem is downstairs;

- Turning over the shock absorber, now it is necessary to squeeze it in a smooth uniform movement;

- We withstand 2-4 seconds and let him go. Everything should return to its original position (if this did not happen, the shock absorber is faulty);

- Pumping must be repeated several times (5-7 times, in this situation, the more pumping, the better);

- Having finished the process of pumping, the shock absorber can be installed, but in no case it should be turned over, it should be in a stem position up, right up to installation.

Tips of professionals

- It is recommended after the end of pumping a two-pipe shock absorber to perform a small check. For this, at the end of the pumping, a sharp movement is necessary to compress the shock absorber for a short distance. Smooth, smooth and uniform move will talk about good quality shock absorber. This check in the ideal should be performed for each shock absorber;

- Installation of the non-pumped two-pipe shock absorber will significantly reduce its service life, which in turn will not be high quality. Pumping the shock absorber is a mandatory attribute of its installation.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments