Modern diesel vehicles have a lot of design solutions to purify the exhaust gas aggregate gases. One of these solutions is the installation of sump filters. But during the active operation, such a filter is able to quickly fail under certain conditions.

Content

- Dairy filter, why it is needed, where it is used

- Pros and cons of car operation with a sump filter

- Spontaneous cleansing, pros and cons

- Signs of contamination of the particulate filter

- Negative effect of a dirty particulate filter on a car engine during operation

- Cleaning the particulate filter using additives in fuel, pros and cons

- Purification of the particulate filter by removal and washing with special chemical solutions, pros and cons

- Substitution of the Saint Filter on New, Pros and Cons

- Removal of the particulate filter from the car engine, pros and cons

- The phased process of removing the filter and installation of a flamesteller or a piece of pipe

- Soft Filter Software

- How to clean the filter without dismantling, removing the pressure sensor and through the resulting hole pour a special fluid, phased work

- Speckens with sprayers for quick cleaning of the particulate filter, phased work

Dairy filter, why it is needed, where it is used

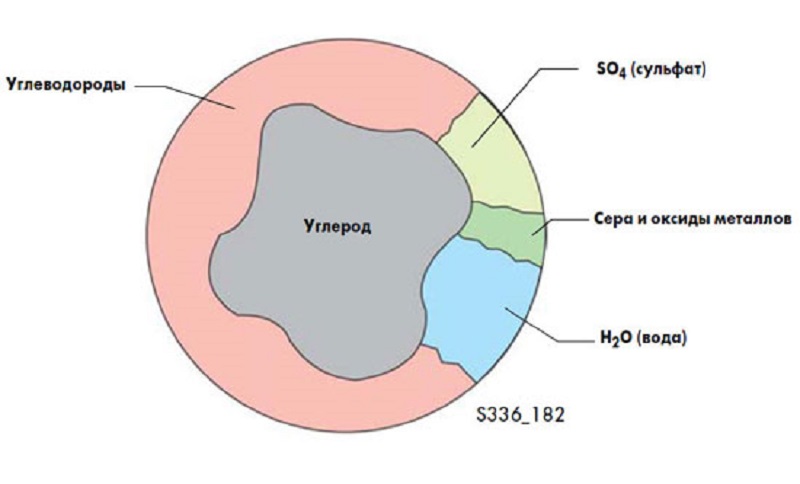

The diesel filter is used exclusively on diesel transport. The main task of the filter element is the trample of soot. The subsequent stage is to host the accumulated soot deposits in such a way that the damage for the ecology has been minimized. Initially, the filter collects South. When the pressure on the outlet from the filter and at the input to it exceeds the specified threshold, the control unit of the motor includes the burden mode. It is worth noting that this fire regimen is activated only under certain conditions, which various manufacturers are specified in their own way. Typically, the power unit should work on high or medium turnover, and the machine must be in motion, and not stand.

Pros and cons of car operation with a sump filter

Advantages of the operation of the vehicle with a smbed filter:

- Excellent environmental performance. The level of emissions of the particulate sediments into the atmosphere is significantly reduced.

- Lack of problems with the operation of diesel vehicles in the European Union.

Disadvantages of the operation of the vehicle with the particulate filter:

- The need to maintain the filter element.

- Unstable engine operation.

- Increase fuel consumption.

- The need for regeneration regime.

- Transition of the car into the emergency mode as a result of a clogged filtering element.

Spontaneous cleansing, pros and cons

The purification of the particulate filter is a prerequisite for its uninterrupted and long work. Without regular cleansing, this filter fails in a short time.

Disadvantages of spontaneous cleansing of the particulate filter:

- Spontaneously purified only at high speeds.

- The cleansing procedure is performed only in the condition of long trips - while driving for short distances, the required temperature may not be achieved.

- So that the procedure of spontaneous cleansing begins, the power unit must necessarily be working.

If the specified conditions fail, the spontaneous cleansing of the filter will not begin.

Signs of contamination of the particulate filter

- Warning signal on the instrument panel.

- Winning, unnatural sound when operating a power unit.

- Increased oil level in DVS.

- Changeable turns of XX.

- Increase fuel consumption.

- Significant reduction in motor thrust.

- Systematic consuming gases of exhaust.

Negative effect of a dirty particulate filter on a car engine during operation

Highly contaminated filter negatively affects the operation of the power unit: the lamps on the instrument panel light up, the fuel consumption increases, the thrust decreases. Fix the position allows you to replace, delete or clean the particulate filter.

Cleaning the particulate filter using additives in fuel, pros and cons

Such additives make it possible to improve several parameters during the operation of the diesel car. A separate category of additives aims to ensure that the Nagar formation procedure becomes much less intense, and is also aimed at reducing the overall level of nagaro-formation and a decrease in temperature during self-cleaning of the cleansing element.

The additives in diesel give diesel fuel to fully burn, which reduces the level of soot in the exhaust. In self-cleaning there is no need for a long time to rold the diesel engine catalyst, in this case the burnout of the catalyst becomes less intense. In the face of a serviceable power unit, as well as if high-quality diest is poured and additive is regularly applied (once in two or three thousand mileage kilometers), additional cleaning of the particulate filter may not be required.

Purification of the particulate filter by removal and washing with special chemical solutions, pros and cons

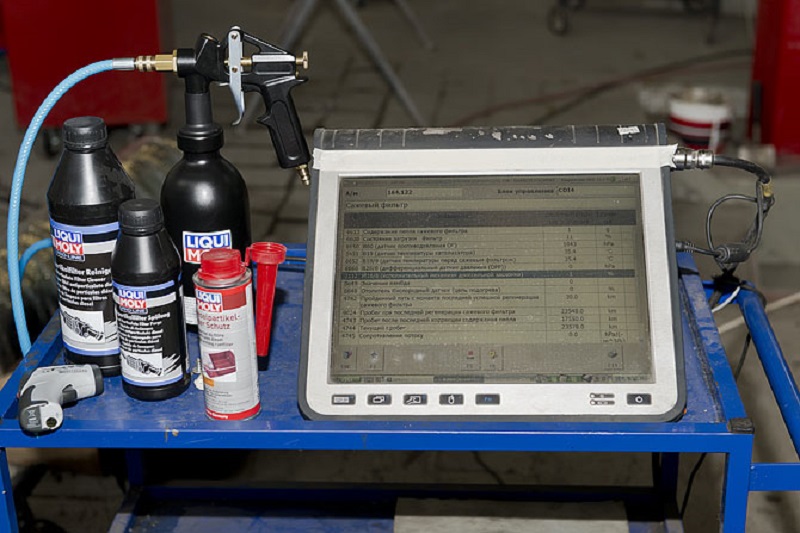

This washing procedure often requires approximately eight hours. At the end of work on the removal of the filtering element, the housing is completely filled with a special flushing fluid. Such flushing fluids for the particulate filters are widely represented on the market. Leaders are such products like Pro-Tec, Liqui Moly, Luffe.

Fluids are created from oil components, usually refer to five-liter canisters. To rinse a high-quality filter with high quality, it is necessary to use at least 4 liters of composition. There may be a special neck in the canister in advance, since further the hose is needed. Also possible variations of canisters, which are already equipped with a finished hose.

As for the principle of operation of flushing fluid, it is based on the fact that the fluid effectively dissolves the resins on which the naiga appeared. Carefully monitor the requirements of the manufacturer of the composition, since it is important to wait for the desired time for the full effect of fluid on the soot.

Then the released soot is washed off under the pressure of the rush of ordinary clean water, which is served on the filter. Next, the filter is dried and put in place. It is worth noting that the solvent of the resin is made on an oil basis, it is normally washed with water and does not cause harm for the structure of the catalyst.

Washing with removal allows for the use of exclusively special fluids, which at the molecular level affect the resin. It is strictly forbidden to use other means, since the matrix in the filter has a fragile platinum layer. When the washing is over, cleaning efficiency is monitored visually. As a rule, this method provides the most efficient and complete cleaning of the filter element.

Substitution of the Saint Filter on New, Pros and Cons

To date, car owners are not often decided to replace the faulty particulate filter on a new product, since it is less profitable, compared to its removal - the replacement will cost several times more expensive. In the original particulate filter, valuable metals are contained and it cannot be replaced with a conventional ceramic insert. In addition, when replacing the filter there is no guarantee that the new will not be released in the near future.

Removal of the particulate filter from the car engine, pros and cons

Advantages of filter removal:

- There is no need for its service.

- Engine operation becomes stable.

- Dynamic car indicators are improving - power increases.

- Decreases fuel consumption.

- The need for regeneration mode disappears.

- No errors, as well as the emergency mode of the DVS due to the clogged filter element.

Disadvantages of filter removal:

- Environmental indicators will deteriorate, the level of emission of the particulate sediments will increase dramatically, but the inspection can be passed.

- There may be problems with the operation of the machine in the European Union.

The phased process of removing the filter and installation of a flamesteller or a piece of pipe

- Get to the location of the scene filter.

- Arming the grinder and cut the compartment with a catalyst and a filtering element.

- We mont into their place a special flame relief or simply weld a piece of metal pipe.

- The installation of the plane maker makes it possible to increase the durability of the exhaust system. In addition, the power of the power unit will increase, and the exhaust sound will become much quieter.

Soft Filter Software

The filter software removal is a more humane method of dismantling the element. It is used if you want to avoid errors in the operation of the motor ECU, which is achieved by adding a lambda probe and an exhaust temperature measurement sensor to a piece of welded pipe. In addition, after removing the filter, you must perform a tuning tuning chip to eliminate the combustion products of black. After performing this procedure, you can notice the reduction in the capriciousness of the power unit in service, but the manufacturer's warranty will have to forget.

How to clean the filter without dismantling, removing the pressure sensor and through the resulting hole pour a special fluid, phased work

The filter element of the diesel engine is equipped with temperature sensors and / or pressure. If the sensor is unscrewed, it will be possible for feeding the flushing fluid. Since the washing is performed by car, manufacturers take into account the possible probability of fireflowing. In such conditions, petroleum products cannot be used. For cleaning, water-alkaline solutions are advised along with a flushing fluid.

Such a liquid has the ability to neutralize malicious alkali at the completion of the cleaning process solution. The fluid is fed into the element housing using a special gun. Also used a curved or direct probe and the nozzle-sprayer.

Probes, sprayers, a set of liquids and a gun make it possible to work with almost any diesel car model equipped with a sump filter. Cleaning by this method involves the dosage and phased supply of the cleaner through the sensor hole. It is possible to install the pressure sensor that is in front of the element.

Instruction:

- The car warms it in advance, then the filter allows you to cool to an approximate mark of forty degrees Celsius - the cleansing alkaline composition is most effective at this temperature.

- For cleaning, it will take about one liter of fluid, which is left in the part of the part for 15 minutes.

- Then the pistol sprayer connects to the curved or direct probe, which is entered into the sensor hole.

- The cleaner is sprayed with interruptions - 10 seconds sprayed, 10 seconds of the pause - it is highly used to the surface of the filter.

- It is necessary that the pressure during sputtering amounted to about eight bar.

- It is advisable to rotate the probe during spraying, as well as move back and forward to achieve the best quality of application.

- Further, the rinse, neutralizing and flushing cleaner spray the same way. It will take approximately 500 milliliters of the cleansing composition.

- The wash is performed using the same spray gun, similar intervals of the pauses are observed. With this approach, the soot is distributed over the matrix more evenly. As a result, it will be possible to show it much more efficiently in the course of automatic self-cleaning.

- After that, the pressure sensor is mounted back, diesel is launched and warming up.

- Then the self-cleaning mode is launched for burning of particles of soot released from bonding resins.

Speckens with sprayers for quick cleaning of the particulate filter, phased work

Nowadays, flushing fluids are also packaged to aerosol cans in order to eliminate the need to apply spray gun. Also, the need for spraying the rinse washing can also be excluded, but it depends on the composition of the cleaner and the specific liquid manufacturer.

- Before use, we shake the canister at least one minute.

- Then remove the pressure sensor to provide access through the hole.

- He warmed a little diesel and the wasting power unit.

- We enter the probe and spray the cleansing agent.

- The cleaner is sprayed for several approaches, and not immediately (5 seconds sprayed, 5 seconds of pause).

- The procedure must be continued until a foam appears in the sensor openings.

- After that, we take a spray probe by setting the sensor removed back.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments