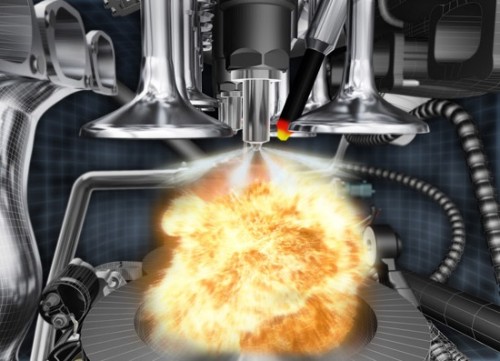

When operating the vehicle, it does not matter, gasoline or diesel, in the combustion chamber and in the intake path all the time all sorts of lacquer and resinous sediments are accumulated, which are capable of calling serious problems with time. The most vulnerable are the injectors of the injection system. And without this, the complex situation significantly worsens the use of poor-quality fuel. To remove these sediments, it is necessary to systematically rinse the fuel system. Depending on which periodicity this event is being carried out, various ways are used. About this further in the article.

Content

- Fuel system, device and principle of operation

- The fuel system clogged, ground signs

- Poor-quality fuel, one of the causes of the blockage

- Flushing fuel system without dismantling nozzles with engine, pluses and cons

- Washing the injector on an ultrasound stand with dismantling of nozzles, pros and cons

- Contemporary equipment for full flushing fuel system

- Fluid for cleaning the fuel system solvent, the advantages of such a washing

- Chemistry for flushing the fuel system of the last generation, features of this wash

- Why washing the injector is better combined with the oil change and oil filter

- Why in the fuel tank poured the composition for cleaning valves

- Tips Profi how to provide a quiet ride

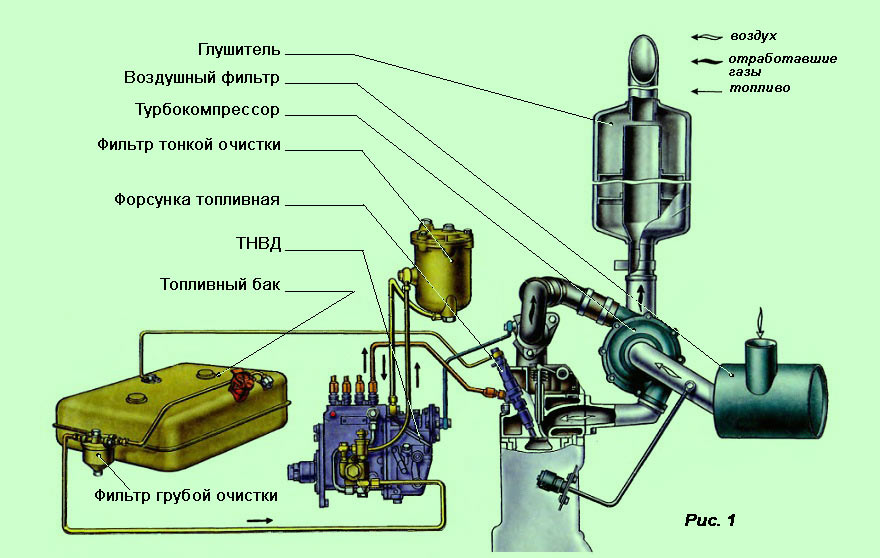

Fuel system, device and principle of operation

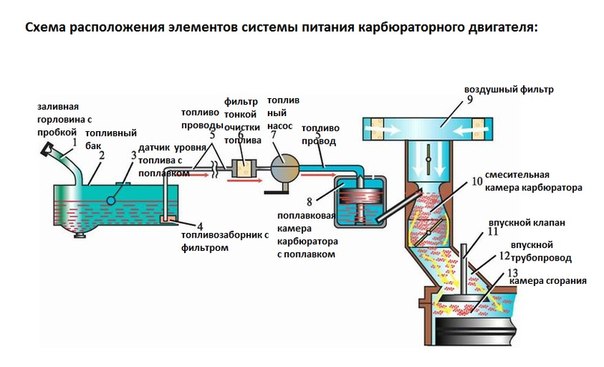

The main purpose of the fuel system of the car is the flow of fuel from the tank, its filtering, the formation of the fuel mixture and its feed to the motor cylinders.

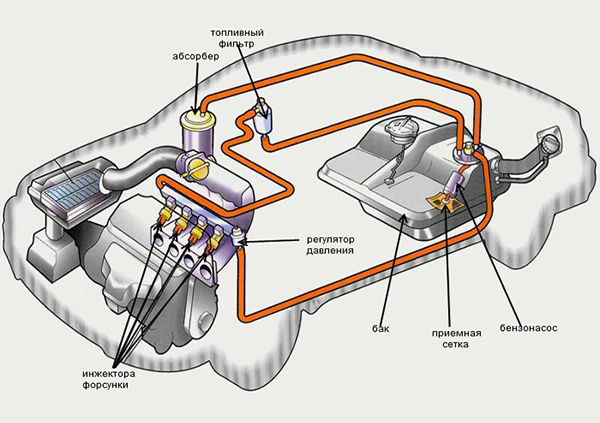

For automotive engines there are several types of fuel systems. In the twentieth century, the most common carburetor fuel supply system was the most common. The subsequent stage is the development of fuel injection using one nozzle (monovosprysk).

The use of this system made it possible to reduce the fuel consumption. To date, the third fuel supply system is used - injector. This system involves supplying fuel under pressure directly to the intake manifold. The number of nozzles is similar to the number of cylinders. All motor power systems are similar, and differ only by mixing methods. The fuel system consists of the following items:

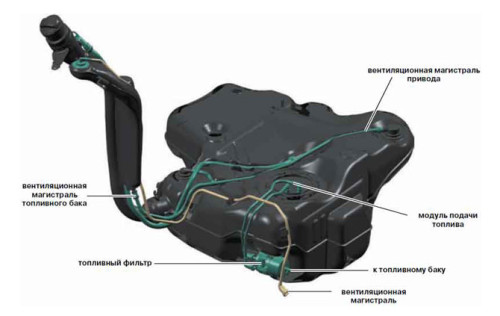

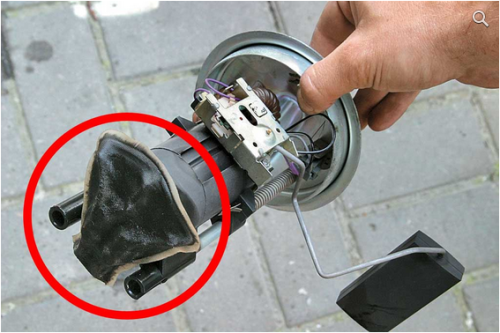

- The fuel tank serves to storing fuel and is a compact container with a fuel intake pump, and, in some cases, with coarse filtering components.

- The fuel lines are a complex of fuel hoses, tubes and are responsible for transporting fuel to the mixing device.

- All mixture formation devices (injector, monofry, carburetor) are mechanisms where air and fuel connection (emulsion) occurs for the subsequent supply to the cylinders.

- The control unit for the operation of the mixing system (injector) is a complex electronic device that is designed to control the operation of control sensors, cut-off valves, fuel injectors.

- The fuel pump is responsible for pumping fuel in the fuel line. It is an electric motor in a sealed case, which is connected to the liquid pump. Lubricated directly flammable. It is worth noting that the long-term operation of the car with a slight amount of fuel can lead to a motor outlet. In some engines, the fuel pump is attached directly to the motor and drives the rotation of the camshaft or the intermediate shaft.

- Additional filters of fine and coarse cleaning are the filtering components installed in the fuel supply chain.

The principle of operation of the fuel system is as follows:

The pump sucks fuel from the tank, after which it is fed through filters of fuel purification filters into the mixing system. In carburetor systems, fuel enters the float chamber, in which then the mixture formation came into the chamber by calibrated juses. The fuel is mixed with air and through the throttle hits the intake manifold, and after opening the inlet valve enters the cylinder. Fuel in the monofry system is fed to the nozzle controlled by the electronic unit. At the required time, the nozzle opens, and the fuel enters the mixing chamber, in which, as in the carburetor device, is mixed with air. Next, the procedure is the same as in the carburetor system. In the injection system, fuel is fed to the nozzles, which are opened using control signals from the control unit. Between themselves are connected by means of fueling, where there is always a fuel. All fuel systems have a reverse fuel line, which merges into the tank of excess fuel.

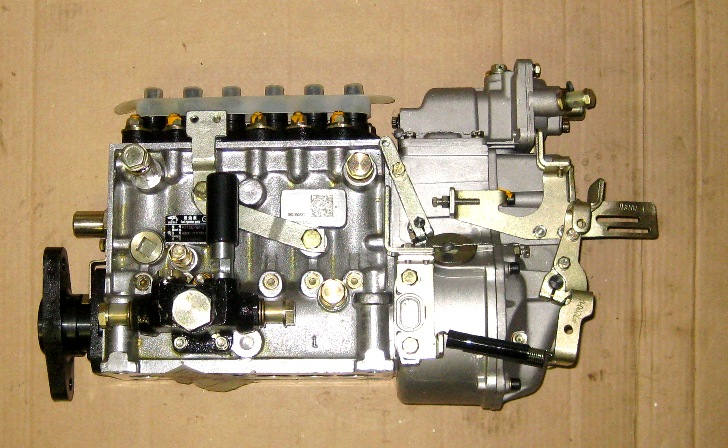

The diesel engine power system is very similar to gasoline. The fuel injection occurs under high pressure directly into the combustion chamber. Makes mixture in the cylinder.

To serve a fuel under high pressure, a high pressure pump (TNVD) is used.

The fuel system clogged, ground signs

There are a number of signs of the fuel system:

- When the nozzles are contaminated, there is a decrease in the specific power of the automotive motor.

- When the car is accelerated, detonation cotton arises.

- Further, the operation of the motor at idle becomes more unstable, the launch of the motor is gradually deteriorating and the level of fuel consumption increases.

- Increases the danger of exhaust.

- Non-permanent operation of a motor in transient modes and idle.

- With a sharp press, the gas pedal fails.

- The catalytic neutralizer and the oxygen sensor of the lambda probe fails.

Poor-quality fuel, one of the causes of the blockage

Some motorists are trying to save, acquiring used cars. However, when buying a used car, it must be remembered that not all previous car owners produce a timely replacement of consumables. In addition, taking into account the quality of fuel, they are unwittingly surprised, as the motors endure him at all. According to statistics, if you are quite often refueling the vehicle on unknown gas stations, you will need to change consumables more often. Sale of fuel is the largest business that requires high payback, but it only happens to well-known fuel providers. Small filling stations often add various additives and even resins.

Flushing fuel system without dismantling nozzles with engine, pluses and cons

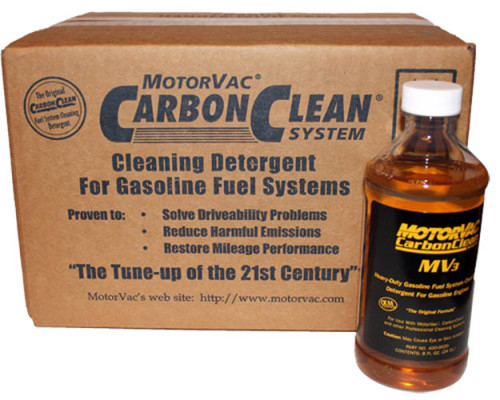

The simplest method of combating deposits without dismantling nozzles is to fill a special fluid into the fuel tank and ride as usual. In this case, the fuel system is complete, not only the nozzles, but also the fuel tank. For these purposes there are many vehicle options, their effectiveness can be very different, so it is desirable to purchase a popular manufacturer's liquid.

This method is great for self-elimination of minor deposits as the prevention of various kinds of pollution. At the same time, it should be borne in mind that if the car has a big mileage, and the fuel system was not yet cleaned, the flushing of the fuel tank can lead to the fact that the deposits on the walls of this tank will score the fuel filter, the fuel pump mesh, and in the worst case, and the nozzles , that is, the problem is only aggravated.

That is why the washing fluid is desirable to use as a preventive agent after a complete flushing of the fuel system with a repeatability of no more than ten thousand kilometers.

The advantages of this method are complete cleaning of the fuel system, simplicity and low cost. The main disadvantage - will not be able to remove severe pollution. In addition, the car owner cannot control the quality of the washing.

Washing the injector on an ultrasound stand with dismantling of nozzles, pros and cons

When washing the injector, only nozzles are cleared on the ultrasonic stand, and other elements, such as intake valves, dispenser-distributor, fuel frame, and pressure regulator with a lock valve are not cleaned.

However, despite this disadvantage, this method is the most effective, since it is possible to estimate the spraying and the performance of the injectors in various modes. In addition, ultrasound is able to destroy the internal elements of the fuel injector.

Therefore, use this method only if the fluid has not coped with the specified task.

The injector cleaning from the inside of the motor is the easiest way out, and in this advantage. Passing through the injector, the solvent is capable of effectively cleaning the inner surface of the combustion chamber and valves. The process itself takes about fifteen minutes.

Contemporary equipment for full flushing fuel system

It is worth noting that the complete flushing of the fuel system is possible only in the presence of special equipment - a compressor that guides the solvent directly into the fuel system during the operation of the motor.

To do this, you need to disconnect the fuel pump, after which the compressor is attached to its place. In the process of flushing the injector from within the motor, it should be remembered that very clogged injectors do not allow to penetrate a sufficient amount of solvent, as a result of which the flushing time increases significantly.

Fluid for cleaning the fuel system solvent, the advantages of such a washing

In the conditions of the auto repair shop, a special installation that feeds the detergent solvent is connected to the fuel ramp. At the same time, the system must be disconnected from the fuel tank. These settings exist single or two-contour. Single-mounted settings are served by solvent directly into the ramp, and the fuel, taking the pump from the tank, returns to a small circle back. With the help of a two-contour installation, a fuel system is cleaned, not counting the fuel tank.

Naturally, it is preferable to apply a two-contour installation. If there is no such possibility, and the fuel line is quite contaminated, you must first wash the ramp to remove dirt from it, as well as not to score the nozzles finally.

With the help of solvent there is an opportunity to rinse the nozzles and on its own. To perform such work, you need to purchase a new fuel filter, washing liquid, the fuel pump of the submersible type, which is powered by the battery and fuel hoses, designed for the sledding of solvent, as well as the removal of excess via the "return".

In addition, the pump can be saved, independently producing a nageneral of a siphon species, where the required pressure will be maintained using the compressor or pump. For these purposes, a plastic canister with a lid is well suited, which is tightly closed. It should be tested the hoses for the fence of fluid and injection of air.

Chemistry for flushing the fuel system of the last generation, features of this wash

The modern market offers many different chemistry for washing the fuel system. I propose to consider the most common of them:

- Wynn's is one of the most famous manufacturers of flushing fluids. It is very strong, excellently removes the nagar from the valves and the combustion chambers, but the cleaner kills the spark plugs. Indispensable for cleaning nozzles on transport over 2002. It is extremely undesirable to use on many cars. For the most new nozzles, it is advisable to use another liquid.

- Liqui Moly - more sparing and tender flushing, after it it is not necessary to change the spark plugs. Its main advantage is that it is possible to wash the injector on any transport, without fear to kill the nozzles. It is recommended for washing systems with direct fuel injection - WV Audi FS, Toyota D4, Nissan NEODI, Mitsubishi GDI.

- LAVR - this flush reminds Wynn's in its characteristics, but its cost is unreasonably large. It is for this that it is so rarely used in car services.

- CARBON CLEAN - washing with moderate characteristics. It is a golden middle between Liqui Moly and Wynn's.

Why washing the injector is better combined with the oil change and oil filter

After washing the injector, it is recommended to replace the oil in the motor and oil filter engine, since a small amount of solvent can fall into the oil system - although this car does not harm the motor (the concentration in solvent oil is quite small and cannot disrupt the balance of its chemical properties). The best option is to wash the injector when planned replacement of oil. Unfortunately, very few workshops, where they remember this at all.

Why in the fuel tank poured the composition for cleaning valves

The composition for flushing the valves is poured into the fuel tank in order to increase the result of the washing of the car injector, since in a few hours of operation of the motor, it is able to remove all car veins from the inlet valves and combustion chambers.

Tips Profi how to provide a quiet ride

After washing, be sure to check the battery balance of the motor and the toxicity of the exhaust, as well as the drop in the pressure of the injectors. Only when receiving positive results in each of these tests, the motor and injectors are considered wellwasted.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments