An experienced motorist always feels like a vehicle behaves on the road, and, on the basis of individual features, determines which system to be diagnosed. If irregularities on the road are increasingly felt in the car's cabin, then most likely it is time to check the suspension or its individual components. About this further in the article.

Content

- Shock absorber, device and purpose

- Checking the shock absorber, is it possible to split the body, modern auto, check the power of the shock absorber

- The shock absorber does not work which troubles threaten the car and the driver if the shock absorber failed

- Checking the shock absorber, how to check the help of the shock absorber with its own forces without dismantling the shock absorber

- How to check the shock absorber on performance using a device with a movement sensor

- Shock Test (Shock-Test) Diagnostics of the shock absorber

- Express diagnostics of the shock absorber

- Checking the load of the shock absorber amplitude-resonant way

- New shock absorbers, how to check the shock absorber at the place of purchase from the seller

- Tips Prof.

Shock absorber, device and purpose

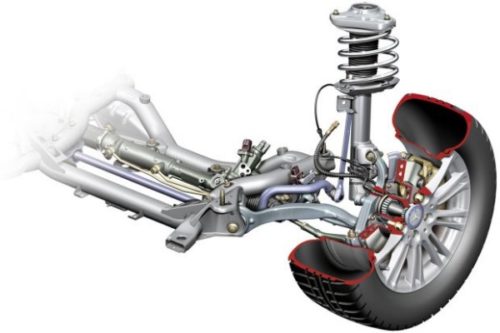

The shock absorber is designed to quench the jolts and shocks, which when moving receives the car body by means of wheels. In addition, the shock absorbers provide reliable contact of the vehicle wheels with the roadpapers. So their destination is not only comfort, but safety.

Previously, cars were not equipped with shock absorbers. Their functions were performed by springs - the quenching of vibrations was made due to the friction of the sheets from became each other. The speed with which cars could move were constantly growing, as a result of which new systems had to develop for safety and comfort. Thus, the racks existed in the form of a block of compressed friction discs, which worked as follows: Vibrations were quenched at the expense of the effort, with which the discs were rotated relative to each other. After some time, it was necessary to abandon such a design, since the discs were quickly wearing and overheated.

In the 20s of the twentieth century, the output was found. The solution to the problem was the use of a liquid that having the vibration of the body, moving from one tank to another under pressure.

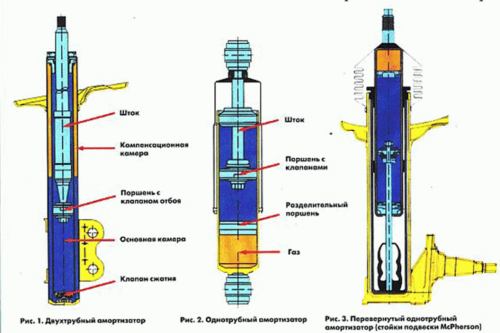

By its design, the rack can be divided into a number of major variations. In structure, they, as a rule, are one-tube and two-pipe.

Shock absorbers are distinguished by the type of fluid, which they are filled - gas (with a gas hydraulic subpode) and hydraulic. There are simply gas shock absorbers, but they are used very rarely. Gas in them is under high pressure (about 60 atm).

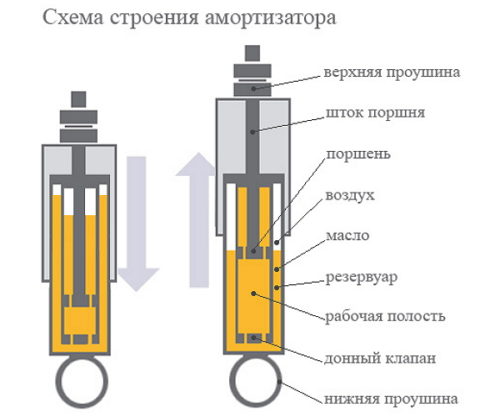

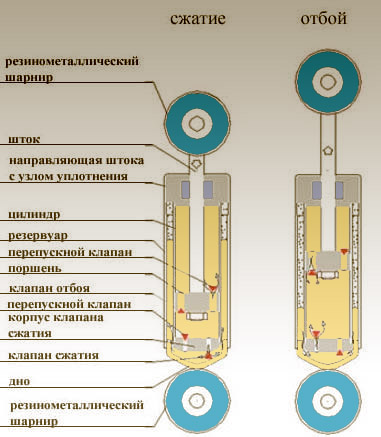

The operation of the shock absorber is the hydraulic resistance or gas resistance. Oil acts as a liquid. There are varieties of racks in which, besides oil, the resistance gives a squeezing and compressive gas.

The shock absorber itself is conditionally divided into piston and cylinder. Inside the cylinder, depending on the modification, there are chambers - or with gas and butter, or with air and oil. In both cases, the piston walks inside the cylinder, dropping and rising. In the second case, the piston resists the pressure generated by a compressive gas chamber. In the first - the piston moves with the resistance, which occurs as a result of the flow of oil by means of valves into another chamber.

Checking the shock absorber, is it possible to split the body, modern auto, check the power of the shock absorber

Earlier, on old models of classic cars with past types and models of shock absorbers, the serviceability of the racks could be determined very simple - with the help of a bunch of body. The complex design of the modern automotive suspension does not allow visually to make objective conclusions about the help of the shock absorber. However, there are a lot of other effective methods that we will consider below.

The shock absorber does not work which troubles threaten the car and the driver if the shock absorber failed

The main malfunction of the shock absorbers is the change in their operational parameters, which occurs as a result of the disruption of tightness, mechanical damage or wear of the working elements (stem) of the shock absorber.

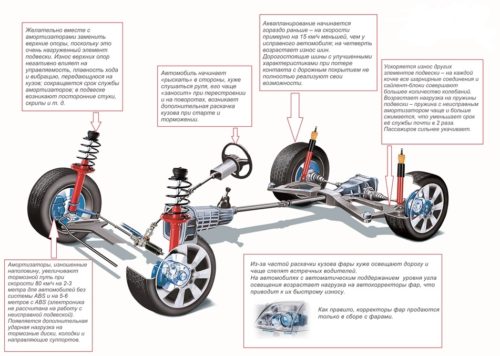

The malfunction of the shock absorbers leads to the following consequences:

- Violation of car manageability. Remember the expression "I did not cope with the control ...". Some drivers sometimes are surprised - well, how can I handle it with him? In fact, everything is simple: when turning the rotation at the speed, the defective shock absorbers made a car spontaneously moving bunch of metal.

- Reducing load capacity.

- Reduced coursework vehicle stability.

- Increasing the brake path, the risk of "care" to the side with extreme or middle braking.

- Acceleration of wear and breakdowns of such suspension components, like supports of racks, springs, silent blocks, hub bearings, shruches, and so on.

- Deterioration of the ride comfort.

Checking the shock absorber, how to check the help of the shock absorber with its own forces without dismantling the shock absorber

It is very important that this method can only check the help of the shock absorber, rather than its performance. The correspondence of the racks by the manufacturer's technical characteristics is a separate conversation.

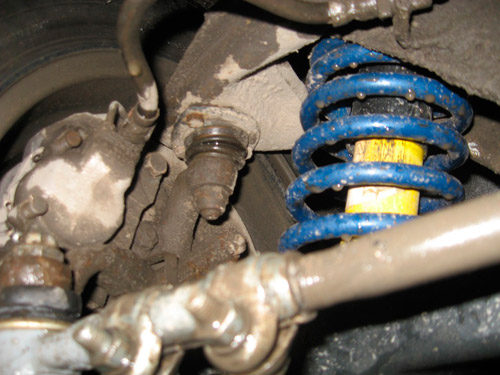

You can independently check the help of the shock absorber without dismantling you can only visually - to diagnose the presence of mechanical damage (i.e. dents) and the goodness of tightness.

If oil leaks and stains are observed on the housing of the shock absorber, immediately draw out the conclusion that the seals were worn out, which indicates the emergence of the shock absorber.

The people there is an opinion that the oil "fog" on the case is a malfunction, but it is not. When the shock absorber is running, this flask is considered a normal phenomenon.

When carrying out the diagnosis of the shock absorber, after dismantling it, it is necessary to pay special attention to the rod - it should not be jackets, traces of corrosion A, especially deformation.

How to check the shock absorber on performance using a device with a movement sensor

This device is "manual". It is attached to the wing of the car, and the sensor is put on the ground. The body rippled produce information. At the same time, factory parameters are introduced into the device, which are the speed of the shock absorber. The performance of the rack is diagnosed in percentage ratio.

Shock Test (Shock-Test) Diagnostics of the shock absorber

Shock test produced on a special stand. The wheels of the axis should be lift and drop sharply. The computer registers the attenuation coefficient of rack oscillations.

Express diagnostics of the shock absorber

Express diagnostics provides sharp braking. It is carried out on a stand with special platforms. At the same time, the brake system is checked. The car must enter the platform and brake sharply. The car body fluctuations are fixed, as well as the load on the platform sensors. Although the accuracy of this method leaves much to be desired.

Checking the load of the shock absorber amplitude-resonant way

Checking the shock absorbers amplitude-resonant method is based on the analysis of amplitude (that is, the values \u200b\u200bof movements) of the platform with a vehicle wheel mounted on it. The platform is reported by oscillations whose frequency is about 16 Hz. As the data is attenuated, the oscillations occurs resonance - an increase in the amplitude of oscillations when the frequency of the fluctuations of the platform and the own frequency of the vehicle suspension. The larger values \u200b\u200bof the amplitude reaches, the worse extinguishes the oscillations of the shock absorber. Next, the stand compares the measurement results with the reference data, after which it issues the conclusion about the performance of the shock absorber.

New shock absorbers, how to check the shock absorber at the place of purchase from the seller

- Outdoor, visual inspection. Check marking. It must match the manufacturer's catalog. Next, you need to check the shock absorber for the presence of various mechanical damage to the glands, housing, rod and so on. Check threaded connections. Of course, there should be no inclusions of oil.

- Checking geometric compliance. You need a caliper and ruler. It is necessary to check the length in the shift state, the rod diameter and the rod move (orient or on the manufacturer's recommendation, or to deviate from the nominal value - ± 5 mm).

- Checking the performance of the shock absorber. Single tube are checked without prior preparation. They should be compressed and stretched for about 3-5 times. The rod must move smoothly, without sharp jolts and jamming, with the same effort. There should be no extraneous creak and noise, in addition to the natural "suggestion", which is the result of the flow of fluid inside the rack. Dual-pipe must be prepared to pre-prepare - pump out several times (3-5), put up vertically, after which it does not turn the shock absorber.

Tips Prof.

Diagnose problems that are associated with the work of the shock absorbers is very simple - the car is noticeably shaking when it hits the bumps, the characteristic tapping is heard. The main problem associated with the arrival of this device into disrepair is that this process occurs gradually (the exception is the gas and oil shock absorbers, which are due to its design, are able to fail instantly). So, the motorist can adapt to such behavior of the machine and do not rush to repair. However, in the meantime, the wear of the tires and the braking path increases, the steering is worse. It may seem to you that these are little things, but, on the other hand, in emergency cases, the malfunction of the shock absorbers can significantly affect their outcome.

It is worth noting that in transport, which is equipped with electronic braking systems (EBD, ABS, and so on), defective shock absorbers will not rarely lead to malference failures.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments