The safety belt is designed to prevent dangerous movements of a person in the car's cabin during a sharp braking or accident, which reduces the likelihood, as well as the severity of injuries. The seat belt was invented in the last century and for the period of its existence he managed to save a lot of human lives. If the safety belt does not work in the car, it must be repaired as quickly as possible or replaced because it is extremely dangerous to ride with a damaged belt and, moreover, contradicts traffic rules. About this further in the article.

Content

- Safety belt in the car, device and principle of operation

- Jammed the safety belt, reasons

- Tools, fixtures, consumables for repair

- How to clean the seat belt without removing the inertial device, how to clean the lock mechanism

- How to clean the seat belt if the inertial device does not work, step by step instruction

- Council Prof.

Safety belt in the car, device and principle of operation

The seat belt is a tape of a sufficient degree of strength, which, with a sudden stop of the vehicle, either in the event of an accident prevents the movement of passengers in the car's cabin. This is the most simple and popular system of passive transport safety. Safety belts were used in 1885, but only thirty years later appeared in serial cars. Machine manufacturers were alerted the appearance of belts. Installation required the attachments of additional funds, which affected the cost of cars and turnover.

When the USSR adopted a law on the mandatory use of seat belts, it was aggressive enough. Activated a variety of arguments against him. But, disputes over time subsided and today belts received very widespread use. Today, only five percent of motorists doubt their needs.

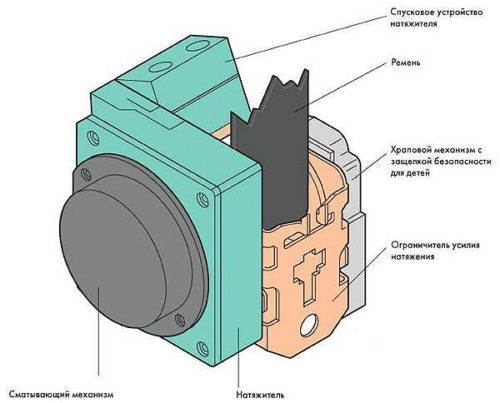

Any belt consists of a retractor device, a lock, fastening bolts and straps. The latter are made from different synthetic materials. Strength of straps directly depends on the quality of the material. A label is sewn to the tape, which has a safety belt marking.

In modern transport, use retractive emergency-locking devices that work on the principle of an ordinary ratchet mechanism. It is blocked using a sensitive element. The basis of the design of this mechanism includes a metal ball and pendulum. When the pendulum is either the ball shift, then the coil is fixed using the lever system.

The coil screw axis has a disk - handwheel. When the driver or the passenger puts on the belt, the strap stretches slowly, as a result of which the drive with the shaft is simply turning. But, in the case of an accident, there is a sharp movement of straps. Overcoming the force of friction, the disk presses on the screw surface and the disk offset occurs, as a result of which it blocks the ratchet.

Jammed the safety belt, reasons

If the safety belt is impossible to pull out the installation slot, then it is likely that he swapped. There may be several reasons for this:

- The reasons are the first - as a rule, the belt is not drawn as a result of its wear. More precisely, wear is not the belt itself, and its blocking systems. This may be due to both the breakdown of the entire system and the malfunction of one of its elements. If the lock is not a fastened belt, it is not drawn, but it cannot be turned off, then it is undoubtedly the case in the mechanism. And half of the beast, if the element was not fastened. It will be much worse when the belt is jammed during operation.

- The bottom of the second is a breakdown of the other component. It concerns, as a rule, it is the fastened strap. If a breakdown occurred or a defect was manifested in the action of one of the elements, it is often associated with the fastened components of the system design. In this case, only repair and nothing else will help you. Well, or, of course, you can always replace the outstanding details.

- Another reason is the blocking after the accident. The design of the strap, as a rule, is designed so that the sickness of the mechanism is triggered when entering accidents. Then the device lock encloses and disable it fails.

Depending on the vehicle model, the driver may receive a message that the belts are jammed. This message can be both light and sound. As for the light signal, it may appear on the dashboard or will be displayed on the onboard computer monitor, if any. But, the warning of the motorist may look different. A loud click that is not characteristic of the security system can be played as a signal. The driver will hear this signal even while driving with loud music enabled. In any case, the car owner will receive an appropriate signal if the vehicle is equipped with "brains".

Tools, fixtures, consumables for repair

- Little gasoline (fuel for lighters is also suitable).

- Syringe with tube.

- Stationery clove.

- Wrench on "17", cape use more convenient.

- Flat screwdriver.

- Conducting screwdriver, better not yet.

How to clean the seat belt without removing the inertial device, how to clean the lock mechanism

- Using a cross-like screwdriver, we unscrew the screws that are fixing the protective lining of the belts.

- If the lock does not work, pull out the belt for the whole length, after which they fix it using the stationery cloves.

- We take a wrench and unscrew the screw fixing the coil of the component. The screw must be removed from the installation site. So that the component does not start wound out, secure it on the coil using the stationery cloves. In any case, to turn off and clean the lock, it should be fixed so that all further actions are made easier.

- Singing the coil to the side, then sit down on the next seat. Next, you need to find a cover behind which the inertial device is hiding. It is usually a little thicker in design. Then you should rub the coil - where the ringing will be heard, the device is located there.

- Now for removing the protective cover, it is necessary to remove four plastic piston. To do this, use a screwdriver with a slotted tip or thin spin. Pistons should be maintained by hand, otherwise they will fly out and you will have to search and collect them all over the cabin. Next, let's upload a screwdriver and dismantle it. Cover set aside.

- Before you the first component mechanism, which is a small box with a cylinder, block block, etc. Rocberry inside. It is he who encourages the castle. This mechanism is freely dismantled from the installation site.

- Check the performance of this rocker - in the perfect version, it should move freely along the axis of rotation. This device should be positioned vertically, otherwise you will also dine. Its upper part must be tilted in the blocking ball area. If you see that the rocker is tight, clean its axis of rotation. To do this, pour some fuel and rinse them the device until it starts to rotate freely, without the slightest jams.

How to clean the seat belt if the inertial device does not work, step by step instruction

- Now we turn to the inertial device, which is made of steel and is located under a gear made of plastic. The gear is dismantled free enough, so we remove it.

- In the center of the toothed hole is an eccentric with kran. It is these cloves that jerks the strap, if it is sharply stronger. To resolve the problem, you need to clean the space under this eccentric. Throughout the opening area, we pour a little gasoline and some fuel add to the center. Simultaneously with these hold the strap, preventing its wigs. The stationery closure is dismantling for a while. Make sure that the liquid gets everywhere, otherwise its cleaning will be useless.

- One hand take a dismantled coil so that the plastic guide along with the spring can be maintained only by one finger. With the help of another hand, we are tightened and wrap the security component several times. Next, pull it several times to engage the mechanism. Then, secure it on the coil one more time. Such actions need to repeat a couple of times.

Council Prof.

This procedure for cleaning the mechanism is completed. Build assembly in reverse sequence. It is important to do everything correctly, because the incorrectly assembled mechanism for regular exploitation of the belts will cause their breakage already in the near future.

You also need to make sure that all components of this node move freely and work correctly. If something is wrong, repeat the cleaning. Only with the right approach you can avoid the main errors and correctly make all actions.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments