Of course, every car owner would like to increase the capacity of its vehicle in combination while maintaining the normal quality of work. This is feasible using the cylinder block boring. The machine with a powerful power unit will immediately show itself on the road. To date, this event is quite popular and make it in every city. However, the boring is not so easy to do. To perform it, it will takes special equipment and skills. About this further in the article.

Content

- Wear block of cylinders, which affects the wear of the cylinder block

- Signs of wear block of cylinders, how to determine

- Cylinder block boring, which gives a boring of a block of cylinders

- Positive moments of boring block of cylinders

- Negative moments of boring block of cylinders

- How to make a boring block of cylinders professionals

- Methods of boring block of cylinders do it yourself

- Council Prof.

Wear block of cylinders, which affects the wear of the cylinder block

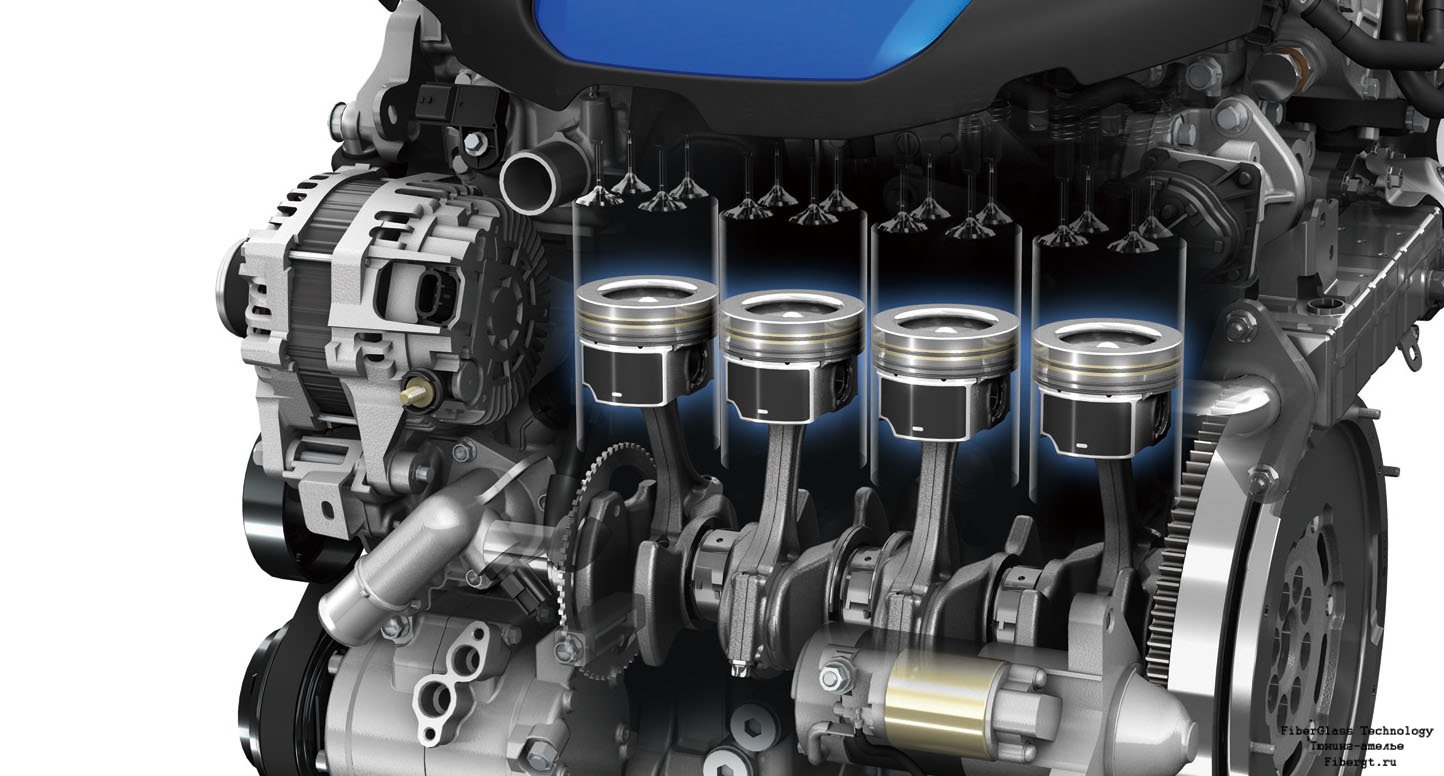

In the process of operation of the power unit on its parts, the load is constantly affected. As a result, gradual wear of the elements occurs. Since the loads in the motor are changing, the cylinder begins to acquire an uneven shape. It is easy to determine using special equipment, but not visually. The piston as a result of deviations on the trajectory can move to the side, and not only up. Because of this, the cylinder has the form of an ellipse (in a longitudinal section). The combustion products also affect the form of cylinders.

In this case, the replacement of the piston to the new will not help. To ensure reliable operation of the motor, such a procedure was invented as a boring of the cylinder block. Milk them due to the substantial wear of the inner surface. To determine the wear, a special degree of evaluation was developed. With the appearance of wear, corresponding to these estimates, it is necessary to perform a boring.

Due to the fact that the cylinder has the form of an ellipse, the piston rings are poorly adjacent, which entails the high consumption of engine oil. In addition, the power unit begins to lose compression, resulting in a serious breakdown, eliminate which will not work. It is very difficult to produce a boring yourself. For the entire event, at least the machine will be required. But it is better to entrust such work with mechanics with relevant experience and qualifications. It is worth noting that the quality of the motor boring directly depends on the qualification of the wizard and the presence of the required equipment.

Signs of wear block of cylinders, how to determine

The first sign of wear is the change in the initial size of the piston ring. If the size changes even by five hundred millimeters, the cylinder should urgently clean. The second feature is the change in size at the points of contact with the cylinder walls with a piston skirt. In this case, even the presence of deviations for three tenth millimeters from the norm is fraught with consequences. As it was already mentioned above, it is impossible to catch such changes to the eye. The presence of wear of the cylinder block is determined using special equipment.

Cylinder block boring, which gives a boring of a block of cylinders

The boring is required to increase the power of the motor. This event gives a power unit the opportunity to get the same size in the block, as well as the symmetric ratio of the holes in it. An additional resource arises that increases the safety of all elements of the motor. In addition, the friction of the piston rings on the wall of the cylinder is reduced, which positively affects the work. As a result, it does not appear enhanced oil consumption. The car behaves better on the road, which gives the driver of confidence.

Positive moments of boring block of cylinders

- Engine power increases.

- Compression increases.

- The car begins to behave better on the road.

- An additional resource appears.

- Movement oil consumption becomes optimal.

Negative moments of boring block of cylinders

- Because of the borsk, the walls of the cylinders become a little thinner. Because of this, during the operation of the power unit, piston rings may overheat.

- As a result of an increase in the working volume of the motor, the efficiency of the vehicle is falling.

- There is a risk that problems may occur during the passage of what is due to discrepancies with the factory motor parameters.

How to make a boring block of cylinders professionals

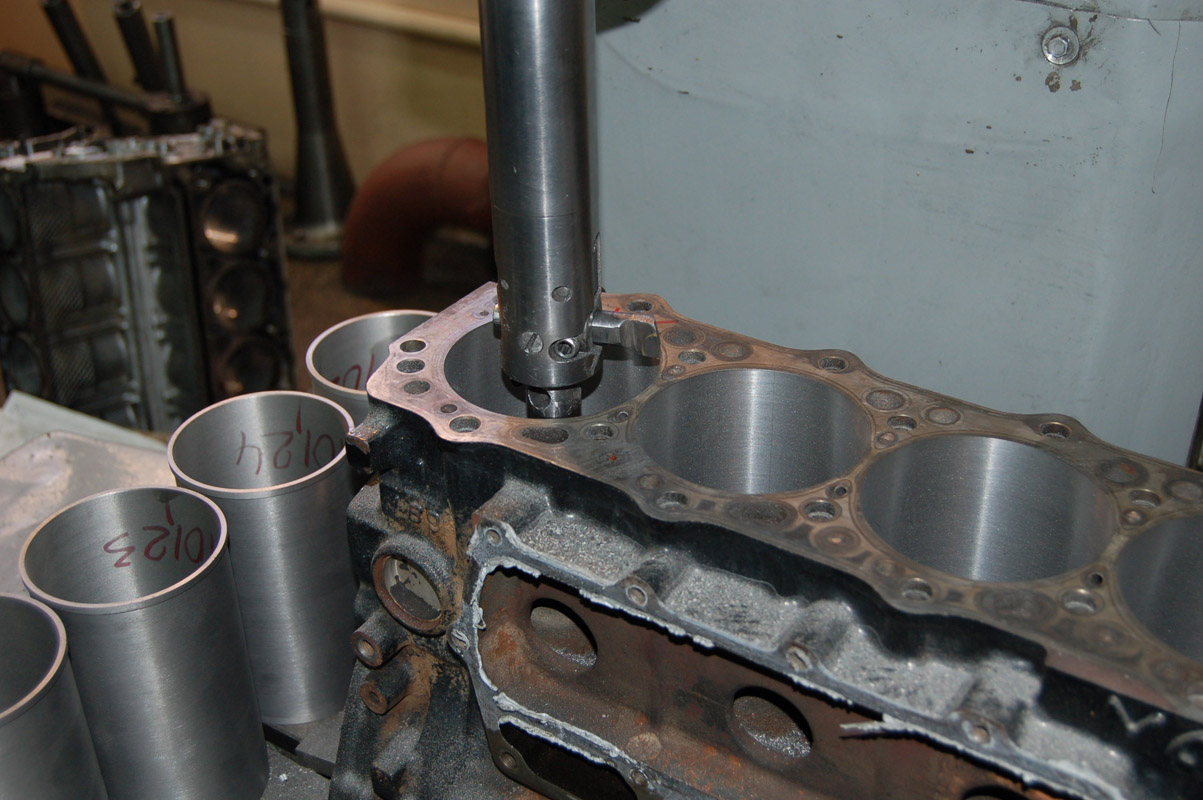

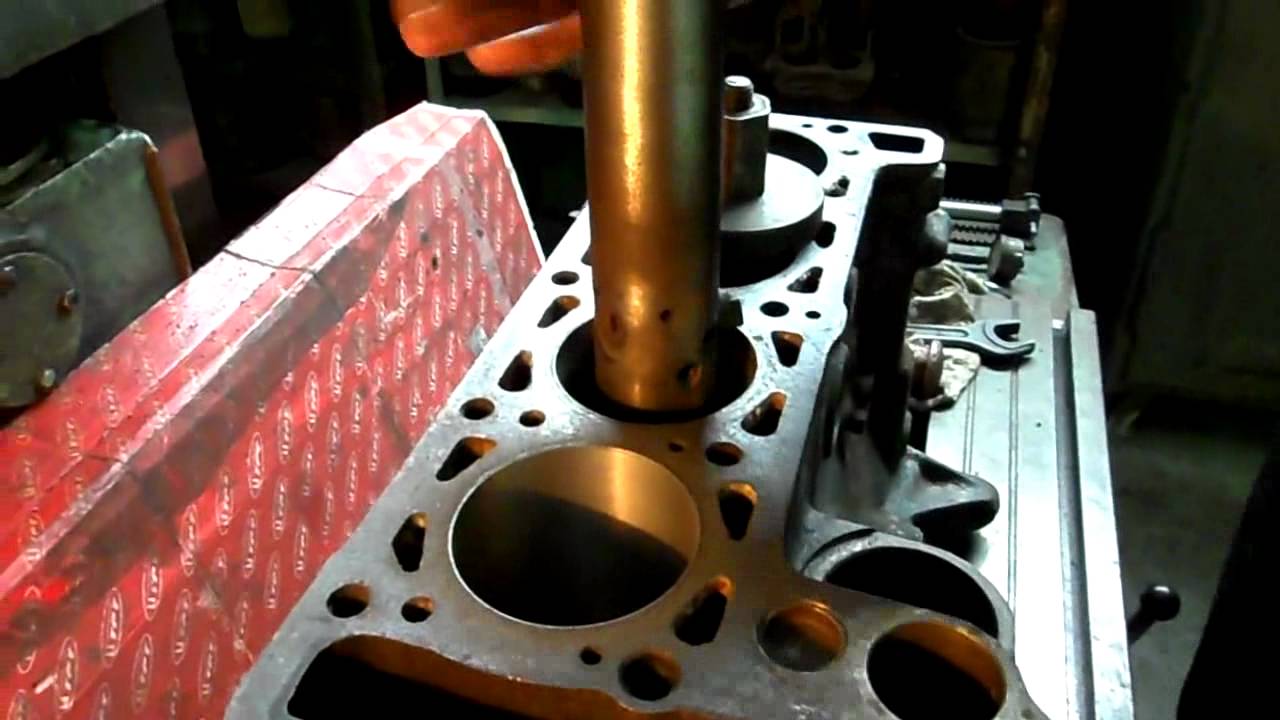

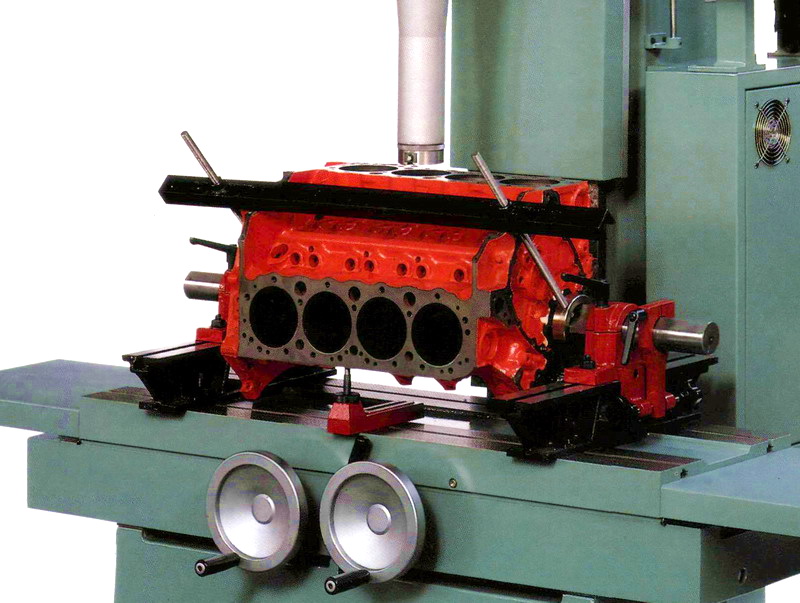

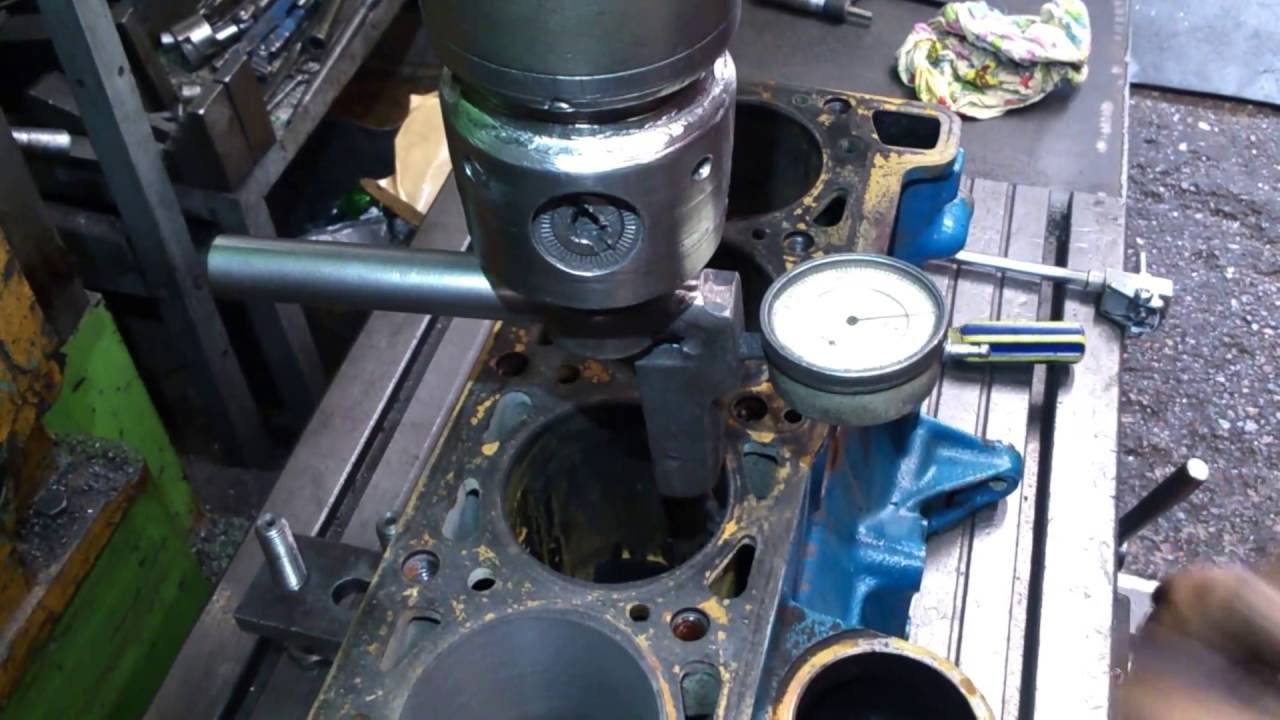

The entire procedure requires the required measurements in order to establish the degree of damage. The boring is eliminated with the taper and ellipse form of cylinders. The procedure requires compliance with all the required conditions and special care. The boring is carried out during major repairs. You need to install the motor exactly without mesh, as this may significantly affect the result. The operation is carried out using a special cutter. A vertical machine is used for boring.

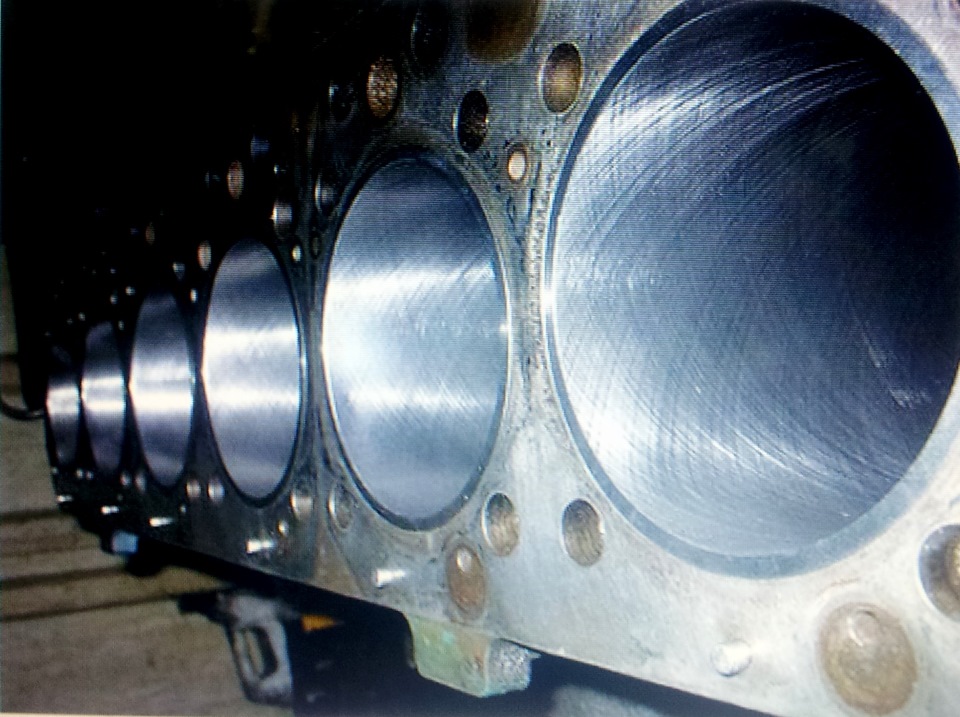

When performing work, everything is controlled using special measuring instruments. Thicketing behind the boring there is honing. Make it on another special machine. As a result, the surface of the cylinder receives additional smoothing.

Methods of boring block of cylinders do it yourself

There are two methods on self-boring of the cylinder block. Methods are complex, therefore requires a lot of effort and free time. Experts advise boring on a special machine.

1 way

For the boring, the usual powerful drill will be needed in the first way. It is necessary to work in such a sequence:

- We take the old unnecessary piston and make a kind of nozzle on the drill out of it. However, pre-cut the incision and wrap the piston of sandpaper.

- Install the cylinder on a flat surface and secure it so that it does not move.

- Put the resulting nozzle on the drill and turn it on on small revolutions.

- We spend the boring cylinder moves up-down. However, make sure that the sandpaper does not fly off the nozzle.

2 way

This method provides a boring with a wooden mandrel:

- It will take an appeal to a specialist to make a mandrel at the required dimensions.

- We supply with a saw or a junction of an incision depth to one centimeter for mounting sandpaper.

- It is necessary to pre-purchase emery paper with small and large grain.

- We establish sandpaper and move to the grinding procedure. We need to make paper with lubricant.

Council Prof.

It is worth noting that it is not always an independent boring brings noticeable positive results. Therefore, it is advisable to contact professionals, which will save your time and strength to save.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments