If the driver on the drive driver will feel the insecure movement of the car at the specified course, if the rubber on the wheels of the car is erased unevenly - the car gives a signal about the need to check the angles of the wheels. In modern times there are a lot of ways to check the correct placement of the wheels, let's try to figure out these methods.

Content

The collapse of the convergence, where to verify the correct installation of the wheels

If the car serves a lot of years, the driver must pay special attention to the rotation of the wheels on the car.

If the wheel alignment in the wheels corresponds to the norm, the driver feels more comfortable on trips, the car consumes fuel much less and the rubber serves much longer.

Therefore, it is necessary to check the collapse of the alignment at maintenance stations.

Modern maintenance stations have new equipment and are interested in clients.

At some maintenance stations, you can still find optical stands for regulating the collapse of the car wheelbarrow. More often than optical stands at maintenance stations use laser installations.

The principle of operation of laser installations is similar to optical stands, but laser installations give fewer errors.

The leader of the adjustment of collaboration is a computer analysis. Computer analysis is a few species.

Alignment-convergence, types of computer analysis of collapse

In accordance with the title, all sizes and results performs a computer.

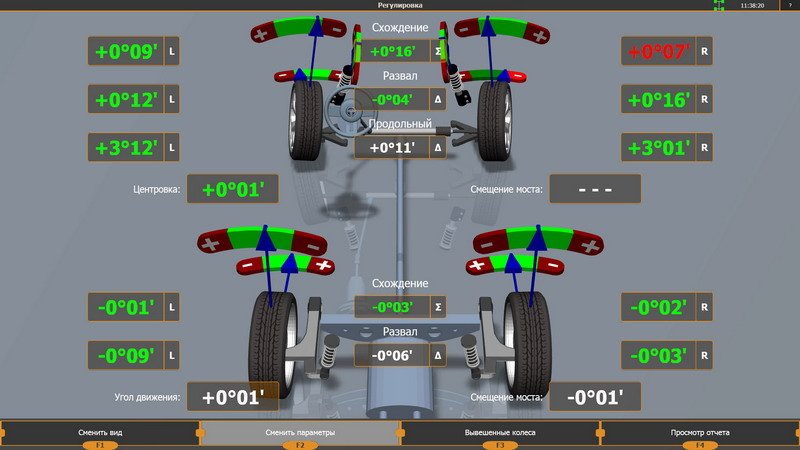

The computer stand has numerous sensors that transmit the operator to the removed data from the car in the form of a graph or diagram.

Based on these graphs or diagrams, the car is configured.

Depending on the sensors and principles of their interaction, computer stands are separated on various subspecies.

The first computer bench that determined the magnitude of the collapse was a cord stand.

During operation, the sensors were attached to the wheels and with the help of wires connected to the computer.

In addition to wires, there are cables that connect the measuring heads among themselves.

Cord stands have greatly proven themselves in work due to the fact that they were easy to use and issued accurate results.

Because of its, relatively, not high costs and good work, in many workshops and in modern times they use a cord stand.

Then a computer infrared stand appeared.

This stand has an infrared beam, it is the basis of the stand.

The beam directed from the sensor freezes the corners of the collapse.

But the new system had low noise immunity.

All that came across the way of the infrared beam, even the sunshine could lead to large errors.

Since the infrared stand had great errors, specialists developed a radio channel stand.

The principle of operation of the radio channel bench is similar to the work of the infrared stand. But, in this case, the signal is transmitted via Bluetooth, this made it possible to increase noise immunity.

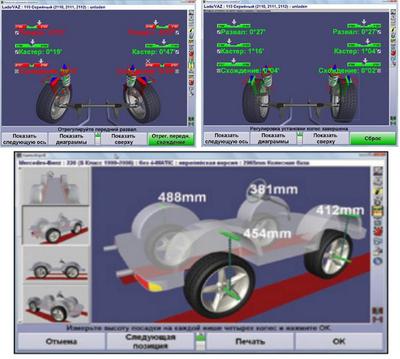

The following computer bench was 3D - stand. 3D - the stand allowed to create a three-dimensional model.

The three-dimensional model has expanded the ability to adjust, made it possible to improve the results and created the ability to diagnose the entire chassis of the machine.

Currently, in diagnostics, a contactless stand is used.

The car is simply drunk on the contactless stand, no sensors on the machine are fixed, as everything is located on the stand itself and is remotely working.

Disorder convergence, which gives 3D diagnostics

If contactless stands are still quite rare at maintenance stations, then 3D diagnostics are available at each major maintenance station.

Diagnostics 3D wins on the background of all previous diagnostics due to the speed of diagnosis.

Due to the fact that the diagnostics occurs quickly, the queues are excluded, since the stand does not need to constant calibration.

3D equipment can issue an accurate result, as it has high noise immunity and the unevenness of surfaces does not affect the accuracy of the analysis.

3D diagnostics is able to make additional information over the entire chassis of the machine.

3D diagnostic playground is equipped with a lift, a pit and a special platform.

Contrast targets are fixed on automotive wheels, the cameras with high sensitivity are followed by these targets and transmit results to the computer.

Having collected all the data, the computer conducts an analysis, issues a 3D model, reconvene the results with the factory values \u200b\u200bof your car. As a result, the computer is issued the result, according to these results, the errors are corrected, the computer is able to issue recommendations on all shortcomings. Modern 3D technology has very high accuracy and are able to issue reliable results.

Almost all factory values \u200b\u200bof existing car models are included in the computer database, it allows the operator to quickly and accurately determine which work you need to do on your car.

Since the equipment is high-quality and reliable, it has become highly popular with Russians and because of the rapid payback price of 3D technologies, quite democratic.

Those motorists who acquire the car on the secondary market should not neglect 3D diagnostics before making a purchase.

3D diagnostics gives you the opportunity to receive information that the previous owner will not voiced.

After all, if the car was in a major accident or was actively used on off-road - the collapse of the convergence can no longer be adjusted.

Only volumetric 3D diagnostics is able to issue an accurate diagnosis.

Of course, if the driver is interested in knowing only the values \u200b\u200bof the corners of his car, this question will help solve him and simpler stands.

And if the driver has many questions to his car, 3D equipment will allow you to resolve all problems.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments