The main transmission and differential are the main elements of the rear axle gearbox. The task of the main transmission is to increase the gear ratio of the transmission of the machine. In this article, we will try to figure out why the rear axle reducer can fail and try to eliminate the problems with their own.

Content

Rear axle reducer, rear axle gearbox

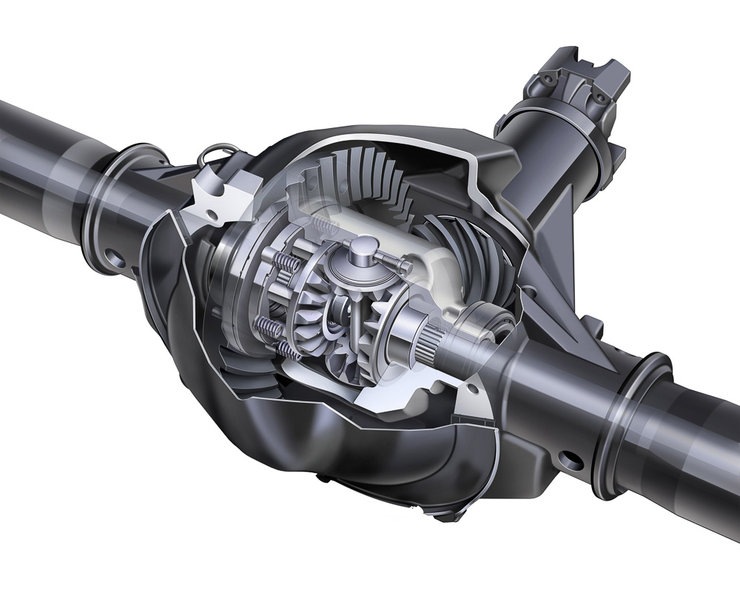

As we indicated above, the rear axle reducer consists of two main parts.

One of these parts is the main transmission.

Depending on the device, the main transmissions are divided into single and double.

Single main gear transmits torque from the motor motor to the wheels with a single toothed pair.

Accordingly, the double main transfer has two toothed pairs. Double main transmission can be like a central (more simple design, has a large gear ratio, but also a large load on system elements), and spaced (this is a more complex design, it is compact and more efficient in operation, compact allows you to increase the car a lumen ).

Consider in more detail the same main gears, they are of different modifications:

- When the location of the gear of the water plane, single main gears are called cylindrical. These gears have a maximum efficiency and a gear ratio of 3.5 to 4.2;

-If gears are perpendicular to each other, such single main gears are called conical. The conical transmissions have a high efficiency, but more bulk design and occupy a lot of space;

-Forny single main programs have proven themselves to be silent work and compactness. The disadvantages include low efficiency and complexity in manufacturing;

- Hypoid single main gears have a small size, so the design is light. Such transfers reliably transmit engine force to the rear axle, but have an average efficiency.

The next component element of the rear axle gear is differential.

Before the differential is the task of distributing the torque between the leading wheels and leading bridges.

If the machine begins to slide or bucks, the differential will help with the help of different rotation speeds.

Rear axle reducer why he can fail

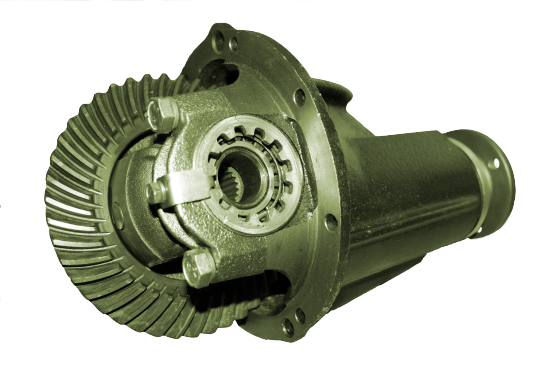

The weak link, which is primarily the gearbox to fail, are bearings, the bearings themselves are made of bronze and are in stockings, stockings are directly attached to the reducer itself.

If the bearing fails, respectively, stockings are outlined. All this leads to the bending of the shaft, and because of the bend of the shaft, the main gear can shift.

Due to the skew in the gear, teeth may be alleged or to form chips. For this reason, the reducer itself can be jammed, and in case the shaft flies from its place, it can break the gearbox body.

Professionals believe that if you do not pour oil in the rear axle reducer, then the absence of oil or poor oil quality, due to late replacement, can cause a gear breakdown. The car owner should not lose sight of the timeliness of service and the oil replacement every 35,000 mileage kilometers.

Rear axle reducer, how to detect a malfunction and make repair with your own hands

If noise occurs in the rear axle area, noise occurs when the machine speed is set, with a sharp slowdown or when turning - most likely the gearbox has any malfunction.

Car enthusiasts who do everything with their own hands will be able to repair the rear axle reducer on their own.

As an example, take the classic car VAZ.

Put on the pit, merge the transmission oil from the rear axle gearbox, with the help of a jack raise the back of the car, secure securely.

Further:

- a cardan shaft, pre-taking the positions of the position of the cardan shaft;

-The rear wheels;

-Tee the brake drums;

-Production dismantling of the semi-axis;

- Recruit the bolts of fastening gearbox with the bridge;

-Tee the gear itself;

"Store a new gearbox, use a sealant when working and put a new cardboard gasket.

Next, we make work in the reverse order, pour oil into the gearbox.

We pay special attention to the gearbox flange and bearings, everything should get up tightly, in your place.

Soon the fairy tale affects, but no sooner is done. Difficulty with removal of brake drums may occur.

During the operation in this place, rust may occur and the metal can be very pressed (to burn).

How to remove the brake drum without damaging it, look at the video:

Rear axle reducer how to adjust it

If the rumble begins to disturb you from the rear axle of the rear axle, this hum usually appears at a speed of 30 km / h.

The hum may appear due to large overloads, due to trailer trips or due to any mechanical damage.

In case of the appearance of the roast, it is necessary to inspect the gearbox.

If some kind of component element (seals, flanges, bearings, satellites and their axes) were worn out, all these elements should be removed, inspect and replace with new ones.

After inspecting all the details, we start collecting the gearbox in the following order:

- the lead the lead gear is put;

-regulatory washer;

- exposure sleeve with bearings;

-flange.

The nut is tightened with a tight, with a special switch, which is built into a dynamometer.

The nut must be tightened to 1N, the flange must stand motionless (it is fixed using a specialized key with spacers).

After the nut is tightened, the driven gear is put in place (in the differential body) and the bolts are tightened.

Now it is necessary to adjust the backup.

After installing the entire mechanism, the nuts need to be tightened to the minimum stop and turn the driven gear.

We draw attention to a small backlash, for this gear we swear from side to side.

The backlash must be mandatory, but small.

During the movement, the gearbox heats up and the small backlash creates a stock for the expansion of the metal.

The final stage comes.

With the help of the calipers, the distance between the bolts is checked, everything must be accurately verified, the nuts must be tightened to the same value so that there is no skew, tighten the gradually, for example, one groove.

Check the gear on the backlash, after a tightening of the bolts, the backlash should remain the same as you set it up.

You have finished work, congratulations!

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments