All TC VAZ-Classics are rear-wheel drive, the movement of the car is performed using the rear axle, which is the leading. The rear axle reducer is the most important element in the transmission, since it is in it the main transmission. It is worth noting that much depends on the gearbox - if he bursts and faulty, the car can at any time stand in the middle of the road. From the PC (gear ratio) of the main pair in the RSM (rear axle gearbox) depends on the speed of the vehicle - than the IF less, the faster the car will move.

Content

- Reducer of the rear bridge VAZ classics, device and principle of operation

- Signs of malfunction of the reducer of rear-wheel drive VAZ

- Causes of the Most Reducer Most of the VAZ Rear Bridge

- Major malfunctions of the rear bridge of VAZ

- Work on adjusting the rear axle gearbox (detail)

- Tools, fixtures, consumables

- Replacement of the rear axle reducer (step by step)

- Tips Prof.

Reducer of the rear bridge VAZ classics, device and principle of operation

To save the car, you need to transmit the rotation of the motor with the wheels. However, the engine has too large revs, and to correctly distribute the torque, you need a mechanism that changes the inverter. Due to the gearbox and different numbers of engine speed, the speed of driving is changing, and the rotation takes on the main pair of the rear axle and transmits it with the wheels through the gears.

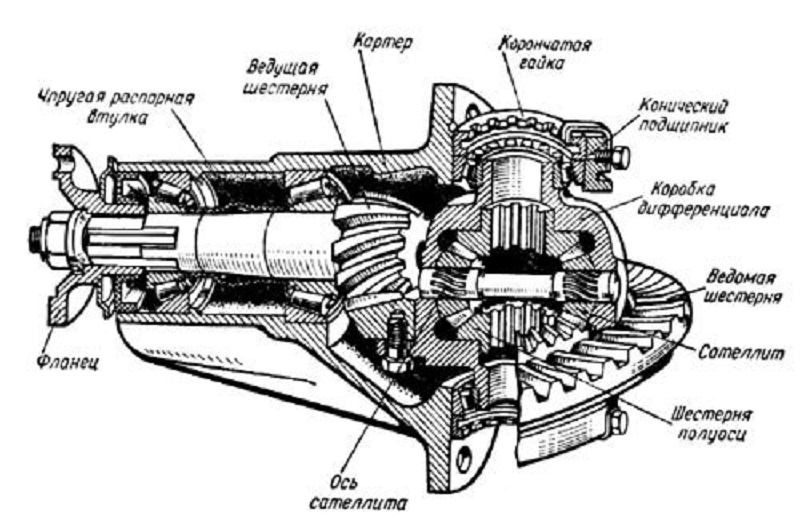

The rear axle reducer consists of such elements:

- The flange, which is fixed on the shank (leading gear) of RSM and is an intermediate link between this gear and the cardan shaft.

- Shank main pair. At his one end there are slots for pressing the flange, and on the other - a conical gear with a small amount of teeth.

- The inter-axis differential, which gives the rear wheels the ability to rotate at different angular speed.

- The driven gear, which forms the main gear in a pair with a leading gear.

Differential device is simple. This mechanism is made of two satellites, satellite fingers and two gear gears. The rotation is transmitted to the semi-axis, where the wheels are fixed.

Signs of malfunction of the reducer of rear-wheel drive VAZ

The main sign of the reduction of the gearbox is its increased noise (hum).

Causes of the Most Reducer Most of the VAZ Rear Bridge

Reducer can be taught for various reasons:

- Bearings were worn out.

- Weakened or died the shank nut.

- Factory marriage of the main pair.

- Gear wear. They have chips and other damage.

- The gap between gears of the main pair is not adjusted.

- There is no oil in the bridge or it is not enough.

Major malfunctions of the rear bridge of VAZ

The main malfunction of the inter-axis differential is to wear the satellites and gears of the semi-axle, when the surfaces of the elements are very worn, the backlash appears between the gears of the differential, but the rear axle is often not cozy as a result of wear of differential gears.

Work on adjusting the rear axle gearbox (detail)

If the main pair is worn, it should be replaced. However, it is impossible to just put the gears in place, the gaps in them are required to adjust. There are two types of adjustments.

- We select the thickness of the adjustment sleeve under the shank. The thickness of the washer can be from 2.6 millimeters to 3.5 millimeters.

- Adjust the gap between the gears of the main pair with the help of two adjusting nuts of the differential housing.

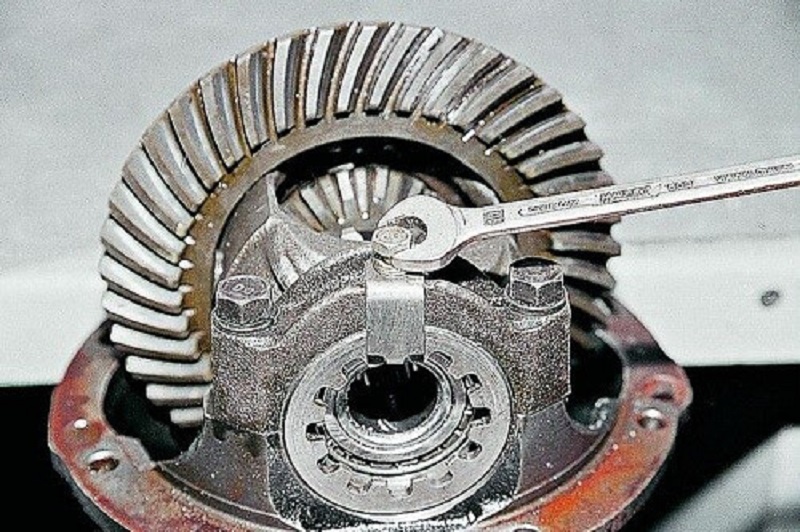

The puck for the shank is selected with the calculation so that the shaft and the leading conical gear be spinning in the gearbox casing with an effort from hand without backlash (0.3-0.4 kg). The shank nut is tightened with a force of 12-26 kg, as a rule, tighten 18-19 kg.

After mounting the shank, the case of a differential with a planetary gear fixed on it is installed. The hull is fastened with two lids. From the beads of bearings, it is necessary to spin the adjusting nuts, and the differential is installed in such a way that the backlash between the gears of the main pair is. It is necessary that the planetary does not be clamped. By moving the adjusting nuts to the left and the right gear shank is supplied to the planetary gear. With the help of adjustment, the moment is selected, in which the gap between the gears actually disappears.

At the last stage, the preload of differential bearings is adjusted, and the adjusting nuts pull up from the sides. Such a robot must be performed with the indicator, the device should show 0.14-0.18 millimeters, the gap between the gears should be 0.08-0.13 millimeters. After the operation performed, fix the adjusting nuts with the plates, in order to avoid turning them.

Tools, fixtures, consumables

To replace RSM, such tools and materials will be required:

- Wooden bar.

- Jack.

- Rubber hammer.

- Embosser for semi-axes.

- Spanners.

- Screwdriver.

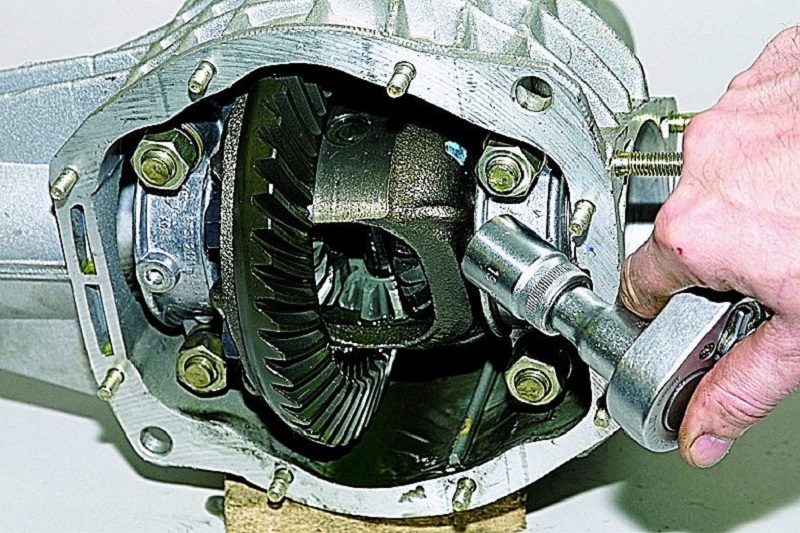

Replacement of the rear axle reducer (step by step)

Order of work:

- Install the car on the lift or pit. Replacing the gearbox on Earth is very uncomfortable.

- If the car is installed on the pit, you should drag both sides, one way or another it is necessary to dismantle the rear wheels. If the work is not performed on the lift, install the stops (in the rear) stops.

- Unscrew the drain plug and drain the transmission oil.

- Remove the rear brake drums, after removing the car from the handbrake. If the drums are poorly removed, dismantle them, tapping from behind the hammer through the wooden bar. It is impossible to knock on the drum with a metal hammer, as it can split.

- Remove the brake pads.

- Each semi-axes of the rear axle are fixed by four nuts. Unscrew them.

- Dispress the semi-axes, for which a special puller will be required.

- Remove the cardan shaft.

- Unscrew the eight rear gear bolts and remove the node.

- Installing the new node and the assembly is performed in the reverse order.

Tips Prof.

We recommend to see the next video:

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments