From most professionals, you can hear that carburetors are a relic of the past, but, nevertheless, a lot of motorists still ride vehicles with such a device. Since the Solex carburetor periodically begins to clutch, its adjustment becomes inevitable. To cope with these works yourself, you should learn all the nuances of this vehicle knot.

Content

Device Carburetor Solex.

In the domestic production machines, carburetors of several manufacturers are installed. For example, manufacturers such as Weber, Solex or Ozone. However, Solex models differ significantly from their analogues and were specifically designed for VAZ 2108 cars.

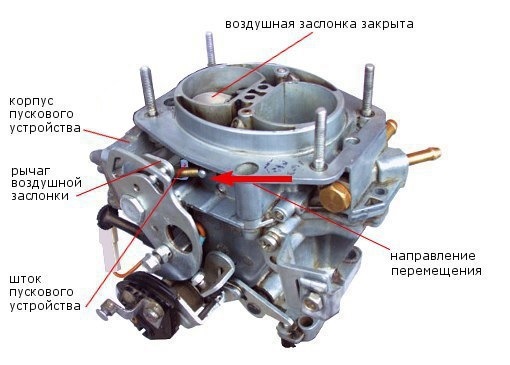

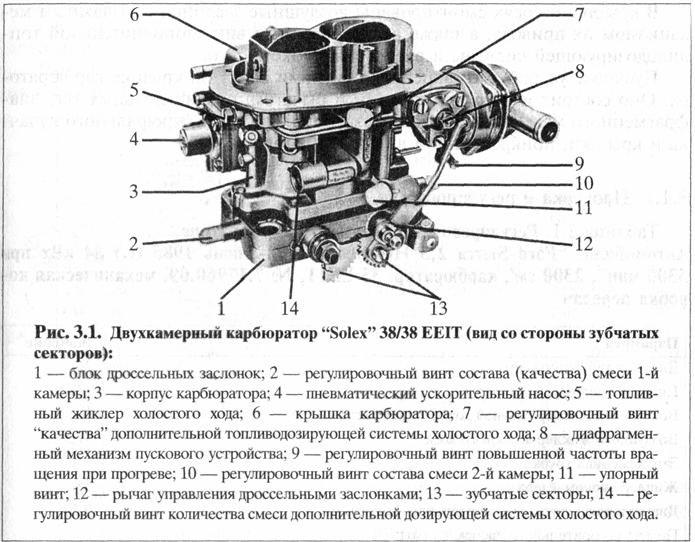

All Solex carburetors are essentially consisting of two main parts - covers and housings. In the housing there are mixing chambers (first and second) with diffusers, emulsion wells, an accelerative pump, eco-status, throttle valves with a starting device and a mechanism of their drive, adjusting screws "quantity" and "quality", economizer, air and fuel channels of carburetor systems, Float camera.

The cover is fastened with five screws to the housing through the cardboard gasket. The lid are fuel fitters, an EPHH solenoid valve, air supply channels to major air jets, a needle valve, an air damper, an eco-bearing sprayer, balancing eyelashes of a float chamber, a neck of mixing chambers and air filter fixtures.

The carburetor has a number of such systems, devices and mechanisms:

1. Playing mechanism.

2. Transition system of the first chamber and the second.

3. Economyer forced idling.

4. EcoPostat.

5. Starting device.

6. Carter ventilation unit fitting.

7. The opening of throttle valve.

8. Acceleration pump.

9. Economizer power modes.

10. System of idle.

11. The main metering mechanisms of the first and second chamber.

The carburetor works badly, why

Just like other details and mechanisms, the carburetor is able to sometimes fail. I propose to consider the main reasons for such a problem:

1.If the quality of the fuel is low.

2. If the vehicle is daily operated in poor conditions, for example, if the technical content of the motor is inactive - excessive moisture, dirt and so on or if you choose a motion mode with large loads for the motor.

3. If the fuel system is incorrect.

The correct diagnosis is to pay attention to

Put the correct diagnosis of the following obvious interruptions:

1. After the speed - if after pressing the gas pedal, the vehicle loses the speed of some time interval, and then slowly slowly accelerated.

2. If jerks occur, which cause twitching the entire vehicle.

3. If overclocking is weak. It may be impressed that someone holds a car for the rear bumper.

4. If speed failures are repeated and go cascading.

The problem may also provoke the inconsistency of the octane number (if it is excessively high or too low) technical characteristics of the motor.

Refinement of the carburetor how to improve efficiency

If you want to improve the efficiency and efficiency of the carburetor, it is necessary to perform its upgrade. There are several options for such refinement:

1. To stabilize the level of fuel, it is necessary to build a locking needle that has greater reliability in operation.

2. Change the level in the float chamber by replacing the valve needle. This gives an excellent effect and ensures the maximum stability of level indicators. In addition, such tuning guarantees an admission to the motor of a balanced mixture of fuel at various transient and high-speed modes of engine operation.

3. You can also withdraw the EPHX system, which will significantly increase the reliability of the engine. In this case, the only negative point is to increase the consumption of fuel in approximately five or more percent.

4. Throttleproof will help achieve several advantages, in particular, improving a more uniform and smooth distribution over the fuel mixture cylinders (such an improvement is needed to work at idle turns) and a significant reduction in carbon dioxide emissions. Such refinement reduces the consumption of fuel to two percent.

5. Polishing diffusers is able to increase the flow rate and reduce aerodynamic losses. In this case, the necessary effect will be achieved only when polishing to the perfect and even state.

How to set up a carburetor, work step by step, in detail

After installing a new carburetor or in its improper operation, there is a need for its accurate configuration. In this case, the exact sequence of all steps of work should be observed. First you need to put the correct level in the float chambers.

1. For this you need to start a motor, warm it up for about five minutes (you can add a pedal a bit of gas) and drown.

2. Maximally, carefully disconnect the fuel hose, whatever the flammable.

3. Then remove the carburetor cover. To do this, we carefully unscrew the five upper bolts, so that there would be no distortion.

4. Remove the tray cable.

5. Now you raise the lid that would prevent breakdown breaks.

6. Next, we measure the height from the bustal surface (with the help of a roulette or caliper) to the level of gasoline. In the first and in the second chambers, the indicators must be 2.4 - 2.5 centimeters. At the same time, it is necessary to take into account the fact that such levels may differ, as the collector does not need exactly the horizontal way, this is necessary to take the average.

7. If you have noticed deviations to a smaller or most side, you need to be adjusted to the desired side of the pump tongue. At the same time, it should be removed from the chamber a little fuel, so that the repeated measurement was more accurate.

8. Now you need to assemble the carburetor back, start the motor and carefully look at the carburetor camera (use to highlight the flashlight). For thirty or forty seconds from small diffusers should not be seized fuel. This should be an obvious indicator that there is no gasoline overflow. However, it is not necessary to gamble, so that there was no splash of gasoline.

After the level is set, the idle setting should be set.

1. Going in the eye of the soles of the carburetor screw quality of the mixture.

2. We take a flat screwdriver and wrap it clockwise until you stop. You should not use force, but you can thread.

3. Turn back to five or six revolutions from this position.

4. We bring the motor, we remove the sublicas and set the minimum speed of the amount of the amount of the mixture, so that the motor work is steadily and the sputum fitting has a minimum discharge. The serviceability of the carburetor speaks revolutions within 500-1200.

5. Slowly wrap the quality screw until the engine starts to work unstable and turn the screw back to one or one and a half turn, thereby returning his optimal work.

6. I exhibit idle speed of the amount of about 850-900. If the motor starts to be stuck, you should slightly unscrew the screw of the quality, adding revolutions.

7. The fifth and sixth items need to be repeated until the optimal relationship is achieved, during which the motor will work steadily, and the discharge in the tube will be minimal.

During the installation of a idling, a number of problems may occur, for example, the motor may not respond to the screw screw. This means that a very large amount of gasoline is received in the XX channel and the quality screw cannot overlap it. There may be several reasons:

1. Almosted too large idling jaws.

2. The plug or solenoid valve is loosely twisted, which is why gasoline passes by a idle gibber.

3. Deformed idling boiler or its seat.

Tips for experienced motorists

The carburetor is a rather important assembly of the motor and the uninterrupted and efficient operation of the entire motor depends on its adjustment. As you yourself were convinced, configure the carburetor Solex can every motorist, but for this you need to perform all work in the exact sequence.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments