The belt of the gas distribution mechanism or abbreviated the timing belt is a binding element, between the distribution and crankshaft. As the rules in the instructions attached to the car, the replacement of the timing belt is strictly regulated. In addition to the replacement, the timing belt must be periodically verified, the entire service life is not only for external damage, but also for tension. The weakened or strongly stretched timing belt is able to deliver a lot of trouble by the car owner.

Content

How to check the timing belt tension

The belt tension of the gas distribution mechanism must be checked when replacing the strap itself, after working with the removal of the belt and periodically, the entire period of its operation.

Checking the tension of the belt of the gas distribution mechanism is elementary, does not take much time and die almost every car owner. Checking the timing belt tension is performed using hands to check the tension is necessary on the longest plot. Rotate the timing belt with two fingers. If the timing belt is hardly rotated by about 70-90 degrees, it means that it stretches normally.

When the belt is too easy to turn or vice versa it is impossible to do. It says, about improper adjustment of the belt of the gas distribution mechanism. The first case means that the belt is weakened, and the second that it is strongly stretched. In any of these cases, immediate adjustment of the timing belt is required, otherwise it threatens serious consequences for the car and considerable financial costs for the car owner.

Important! Properly stretched timing belt, fluctuates in the tails of 1 centimeter, from its own axis.

There is another way to check the timing belt tension. To take advantage of this method, you will need manual spring scales and caliper. To acquire all necessary manual scales, it is necessary to hook with a crochet in the middle between the camshaft pulleys and pull the scales to the mark of 10 kilograms. Having achieved the required mark, it is necessary to measure deviations from the standard position of the belt of the caliper, it should be 5.5 + - 0.2 millimeters.

timing belt tension norms

- Normal tension of the belt of the gas distribution mechanism, it is customary to consider the maximum point of rotation of the belt 90 degrees at an effort of 2 kilograms or 19.6 Newton.

- Deviation when exposed to 10 kilograms of 5.5 millimeters.

Tools assistants for tensioning belt timing

To adjust the tension of the timing belt, we will need:

- Special key for adjusting the timing belt. If it is not available, you can use two nails and a screwdriver or make a similar key from the steel plug;

- Standard set of keys.

Interesting! In the absence of a special key to adjust the timing belt, it can be made with your own hands from a conventional steel plug. To do this, break down two central teeth, a little shorten the side and bend them.

Tension belt timing with their own hands, work stages

To get all necessary, you can proceed directly to the stretch of the belt of the gas distribution mechanism:

- Open the car hood;

- Remove the protective flap from the timing belt;

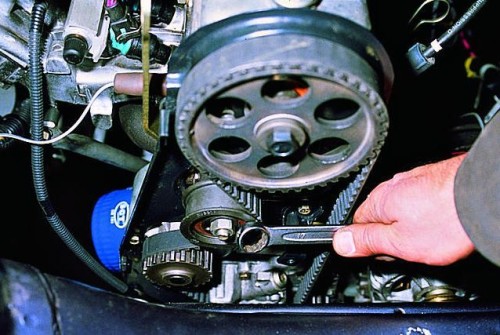

- Weaken the nut, which is attached to the tension roller;

- With the help of a special key, we adjust directly the tension roller itself. Clockwise weaken the timing belt, and counterclockwise pulls respectively;

- After adjustment, fixing the roller in the required position, you need to tighten the fastening nut of the tensioner directly;

- Checking the tension of the timing belt;

- If the belt is adjusted correctly, install the protective flap in its place.

Replacing the timing belt, work in stages

To replace the belt of the gas distribution mechanism, we will need:

- Standard set of keys;

- Special key for adjusting the timing belt;

- Tool for checking the timing belt tension;

- Directly new timing belt.

Replacing the timing belt with their own hands can only be performed by people with sufficient experience and knowledge. Improper installation of the timing belt will certainly lead to additional financial costs.

Prepare everything you need can be proceeding directly to replacing the belt of the gas distribution mechanism:

- Open the hood;

- Remove the protective shield of the timing belt;

- For the pulley mounting bolt, with the help of the key turn the timing belt so that the piston of the first cylinder stood in the upper dead point in the compression tact. To do this, it is necessary to set the labels on the gear of the camshaft and the timing cover opposite each other.

- By installing the piston of the first cylinder into the required position. With a screwdriver, lock the crankshaft in the desired position. To do this, it must be inserted between the flywheel's teeth in the clutch crankcase;

- Now remove the pulley of the generator drive. To do this, unscrew the bolt that crepts it;

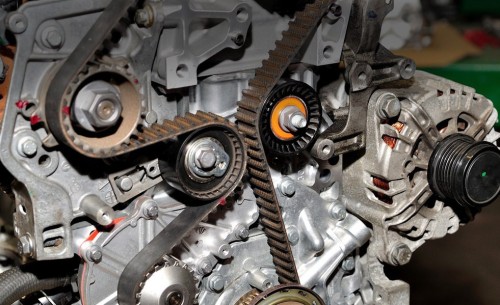

- We relax the fastening of the tensioner and turn it to maximize the timing belt;

- Remove the old timing belt;

- We put a fresh timing belt on the crankshaft pulley, and then on the pump pulley;

- We bring the fresh timing belt directly for the tension roller;

- We put on the fresh timing belt on the camshaft pulley;

- Now we produce adjustment of the timing belt tension, as described above;

- We put in your place a protective shield of the timing belt.

Professional advice

- Experienced specialists are recommended to test the tension of the belt of the gas distribution mechanism every 13-15 thousand kilometers. The crash of the timing belt is able to get the valve, according to statistics, this occurs in 87% of cases.

- In no case should not operate a vehicle with a worn or incorrectly strained belt of the gas distribution mechanism. Replacing the timing belt or adjust it stands at times cheaper than the consequences of his cliff.

- The timing belt tense is too long in reinforcing wear of the belt itself, as well as rollers and bearings. A weakened timing belt is able to jump, while it bends the valve and tears it also directly the belt itself, which leads to considerable financial costs.

- In the case when the belt of the gas distribution mechanism is pulled, the screech is clearly heard.

- You should not allow any lubricants to the timing belt - this significantly reduces its service life.

- When replacing the timing belt, it is also necessary to make a thorough inspection of all rollers. According to experts, the replacement of all rollers should be performed on each even replacement of the timing belt, that is, every second replacement of the belt of the gas distribution mechanism changes and rollers.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments