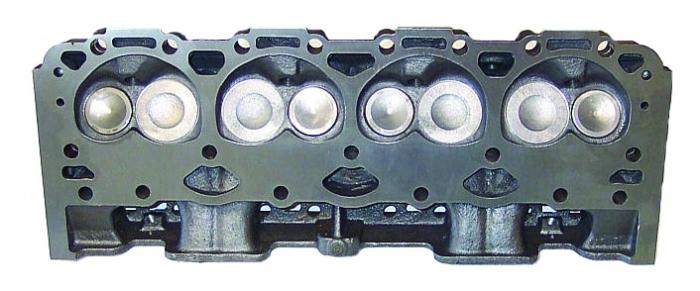

The head of the cylinder block is one of the most important elements of the internal combustion engine. As a rule, this is a monolithic element from cast iron or aluminum alloys, which forms the upper combustion chamber department and is a housing for the gas distribution mechanism. It is usually installed through a gasket on the cylinder block and fasten with bolts.

Content

GBC, GBC device

The head of the block performs such important functions as:

- Provides the maintenance and placement of the elements of the gas distribution mechanism, the components of the removal and flavoring components.

- Provides gas-dynamic characteristics of the air charge, remove combustion products from the combustion chamber.

- Forms a combustion chamber and provides its tightness, brings and removes oil for elements of the gas distribution mechanism.

- Provides the vehicle compliance with environmental standards for emission to the atmosphere of harmful substances.

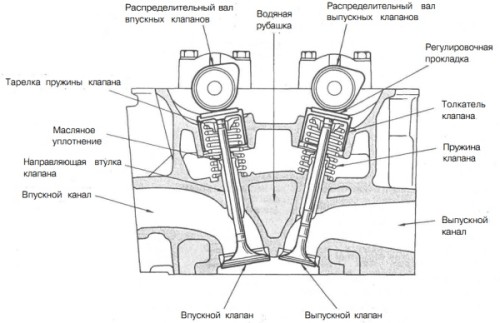

The cylinder head includes:

- Guide sleeves.

- Valve seat.

- Hydrocompensator (can go bundled with a rocker).

- Rocker valve.

- Traverse.

- Spark plugs (for gas and gasoline engines).

- Springs to return to the starting position of the valves.

- Fuel nozzles (usually used in diesel engines).

- Graduation and intake valves.

The material from which the cylinder is made can be aluminum (for example, CFC VAZ 2109) or pig-iron (diesel). As a rule, for manufacturers in priority aluminum heads, as they are the most convenient in processing, manufacturing and repair. However, on some diesel engines, cast-iron heads are used, because the detonation properties of diesel fuel are superior to the strength parameters of aluminum heads, which can lead to a reduction in operating life or to the destruction of the GBC.

GBC can be divided into two types - mono-heads and individual heads. The latter have several advantages that are related to maintainability, low cost and simplicity for maintenance. However, most of the world's vehicles and autoelempics prefers monogols, which also have their advantages.

The principle of operation of the GBC: the camshaft pushes the bar, which presses the hydrocommoventrator, and then on the rocker, which puts pressure on the valve, which opens and penetrates the combustion chamber where the candle is flammable.

Repair assistants tools

- Manual for the maintenance and repair of your vehicle.

- Dynamometric key.

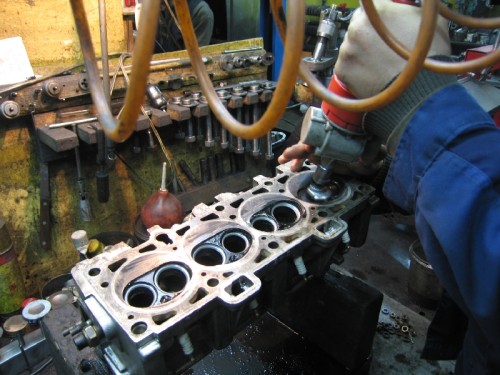

CHBC, how to remove the cylinder headguad instruction

- First you need to disconnect and remove the battery, drain the engine oil and coolant.

- Then you should make dismantling of attachments, in particular, disconnect the ignition wires, disconnect all hoses - cooling systems, vacuum. Do not forget when disconnecting hoses and wires to make them marking.

- Next, dismantle the fuel lines and the accelerator cable.

- After that, we remove the rest of the attached equipment that interferes with removing the block head.

- Now remove the cylinder head cover.

- Then dismantle the casing of the gas distribution mechanism and the pulley belt. The camshaft can not be touched.

- We unscrew the cd fastening bolts and remove it.

GBC bolts, how to remove the GBC bolts according to the scheme

Turning the bolts of the cylinder cylinder bolts simultaneously with the help of a dynamometric key, controlling the state of the bolts.

Do not forget about the compliance with the sequence during the promotion, which should be the return tighten. Removing the CBC bolts must be carried out according to the appropriate scheme, which is individual for each transpotator model and can be found in the car operating manual.

Diagnosis of GBC.

- The visual inspection method it is necessary to detect visible defects - worn out of the valves, sinks from corrosion, broken studs visible to the naked eye of a crack, disrupting the threads, candles, and so on.

- Sealing the cooling system of the GBC, fill with gas under pressure and immerse in hot water. The crack find on emerging bubbles. At the moment, this method of diagnosis of the GBC is the most effective. Ultrasound and X-rays have not yet justified.

Replacing bushings, repair sleeve valve, step-by-step instructions

- Slowly and extremely carefully knock the sleeves.

- Clean the released place.

- It is advisable to blow the sleeve with compressed air.

- New sleeves should be withstanding about two days in the freezer, whatever they have been compressed and smoothly fit in the landing location.

- Heat the GBC on the electric stove to expand the seats.

- We put on the locking rings on the sleeve, insert into the holes and carefully begin to drive them into the holes.

Titted valve saddles, wishes task

To date, in fact do not apply this operation. If the chamfer of the valve and the saddle are accurately processed, then the trigger is not needed at all. Another thing during manual processing of elements by incisive heads and cutters. After repairing the surfaces may have a small roughness.

Print is necessary not only for processing, but also to monitor the quality of the conjugation. If you wipe dry surfaces and turn the valve in both directions several times, pressing the seat, then a shiny line is formed on the chamdes of the elements. If it is closed and pass throughout the circumference, it is good and everything is done correctly.

Tips of professionals

More useful information about the repair of the head of the block you can learn from the video:

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments