To facilitate the control of the car in modern transport on the steering column, the hydraulicer is mounted. One of the key components of this mechanism is a pump, pumping hydraulic fluid on the GUR system. In the course of operation, it is subjected to high loads, so the need to repair the pump gur systematically appears. About this further in the article.

Content

- Types of steering wheel amplifiers

- Gur device and principle

- Pump gur why he fails

- Causes of the failure of the pump GUR

- Signs of failure of the pump GUR

- Remkomplekt pump GUR, which is included in the kit, where to purchase it

- Preparation of workplace

- Tools, fixtures, consumables

- How to remove the pump gur, step by step

- How to remove the bearing in detail

- How to check and clean the details of the pump GUR

- How to assemble the pump gur step by step

- When and how to change the pump GUR to a new

- Tips Prof.

Types of steering wheel amplifiers

Currently, there are five types of steering amplifiers:

- Hydraulic steering wheel (GUR).

- Electric power steering (EUR).

- ElectrohydroSiller steering wheel (Egur).

- Pneumatic steering wheel.

- Mechanical steering amplifier (steering mechanism with an increased gear ratio).

Gur device and principle

The purpose of the steering hydraulic power plant is not only facilitating the motorist control of the vehicle during maneuvers, A and soften the blows from the damaged road linen and irregularities. It is especially important that the GUR significantly reduces the risk of an accident in the conditions of a tire break, especially on the front wheels.

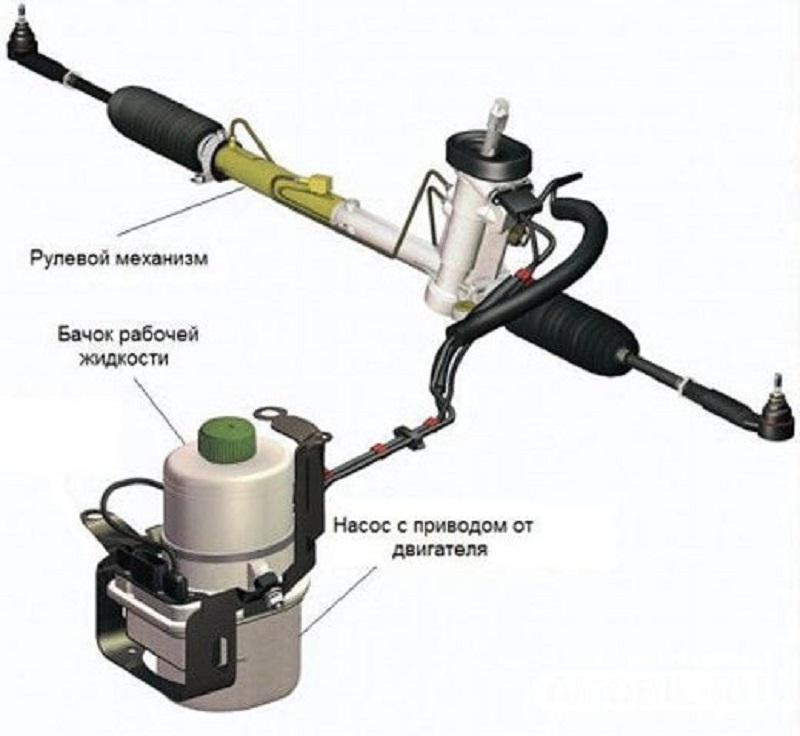

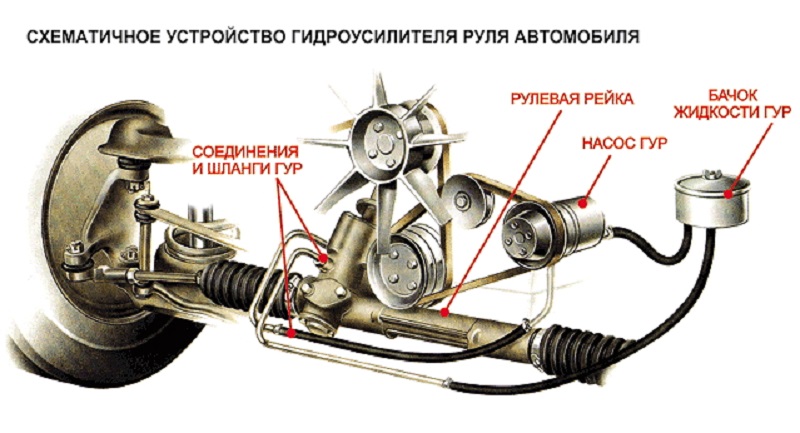

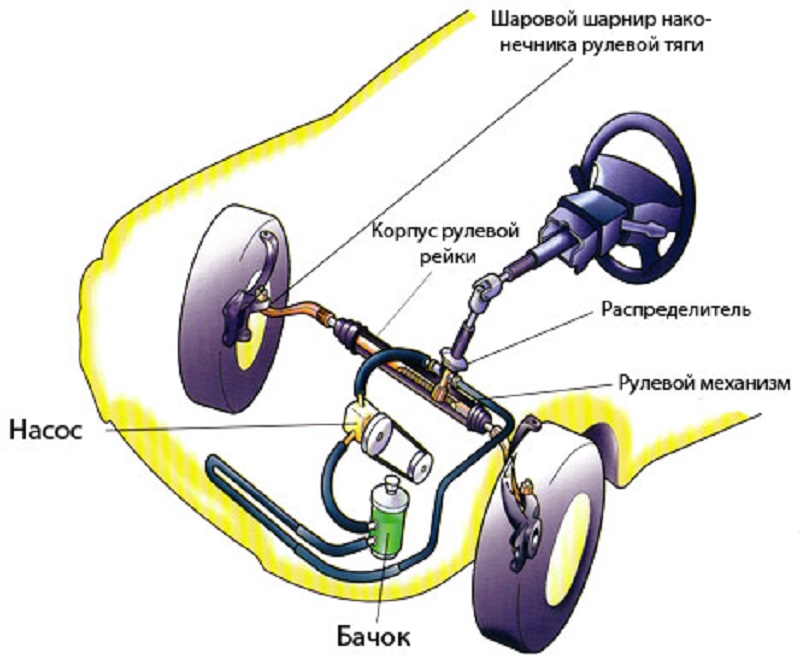

The hydraulicel is a closed hydraulic system, which includes:

- Power cylinder. Also called a hydraulic cylinder. Performs the rotation of the wheels. The liquid in the GUR pressure under pressure on the piston and makes the stock shifting that it entails the rotation of the wheels. To slip back the rod, the liquid presses on the piston from the reverse side, and the wheels are returned to the original position. The hydraulic cylinder may be or on the steering mechanism, or between the vehicle housing and the steering drive.

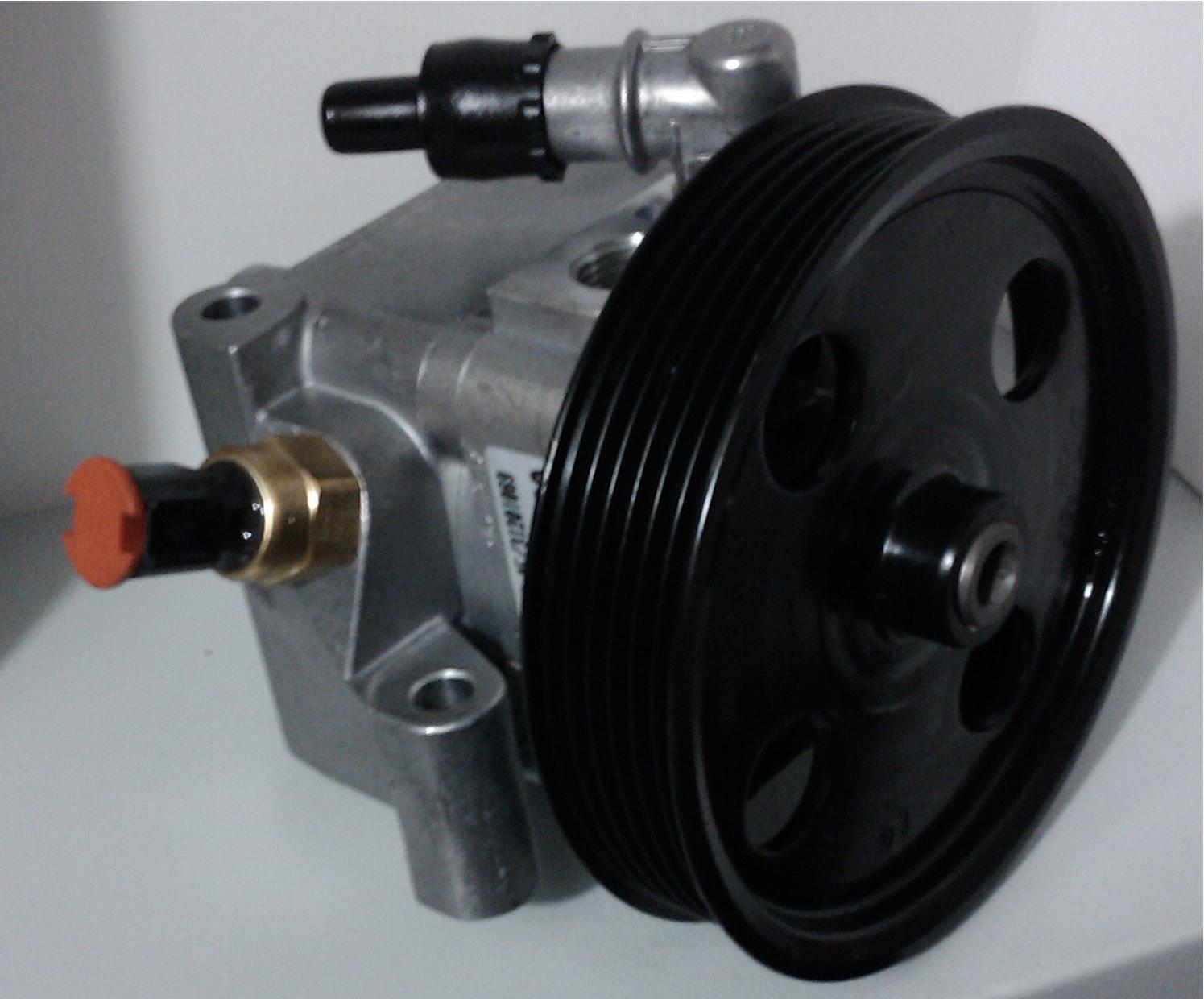

- Pump. It is the main part of the structure of the steering wheel hydraulic. With its help, pressure is created in the hydraulovel and circulation in the oil system. It is attached near the motor and operates from the crankshaft using a gear or belt (drive).

- Switchgear. A kind of adjustor, guiding oil from a tank to a hydraulic cylinder, and then back. Mounted or on the shaft of the steering mechanism, or on its other parts. There are two types of distributors: a rotary (a spool performs rotational movements) and axial (translational).

- Tankwhere the hydraulic fluid is refilled, ensuring the functioning and lubrication of all components of the hydraulic agent. It has a special filter to protect against dirt from entering, since the distributor is very sensitive to this. Oil level is checked by a special probe. The tank has a cylindrical shape and is located under the hood, as a rule, in the prominent place near the tank with antifreeze.

- High and low pressure hoses. High pressure hoses provide the circulation of fluid between the hydraulic cylinder, the pump and axial or rotary distributor. Low pressure hoses return this oil from the distributor to the tank, as well as from the tank into the pump. It is necessary to monitor the state in which the hoses are located, in order to avoid leaks of liquid, as well as breakdowns of the entire mechanism.

Pump gur why he fails

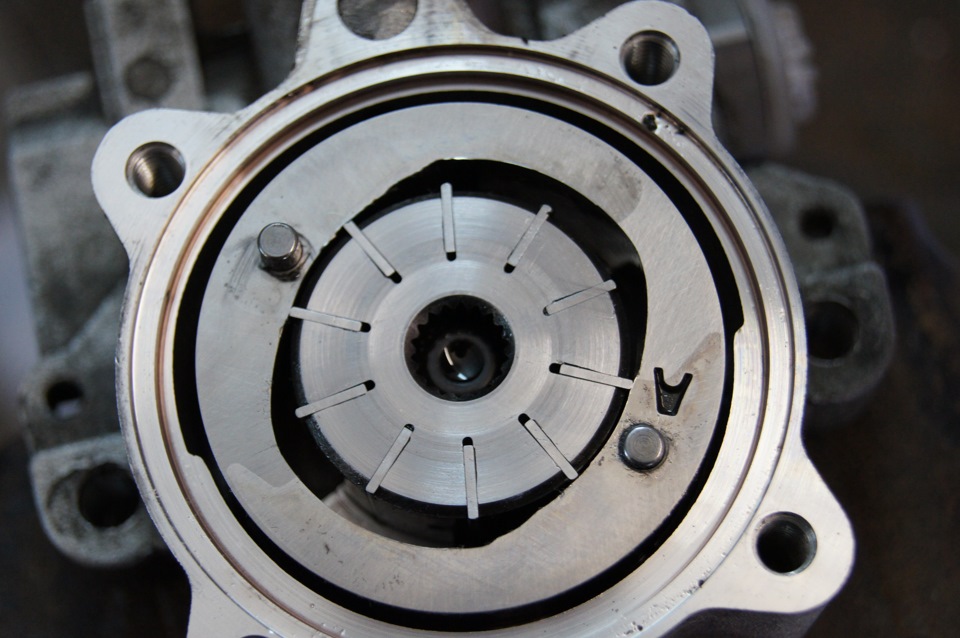

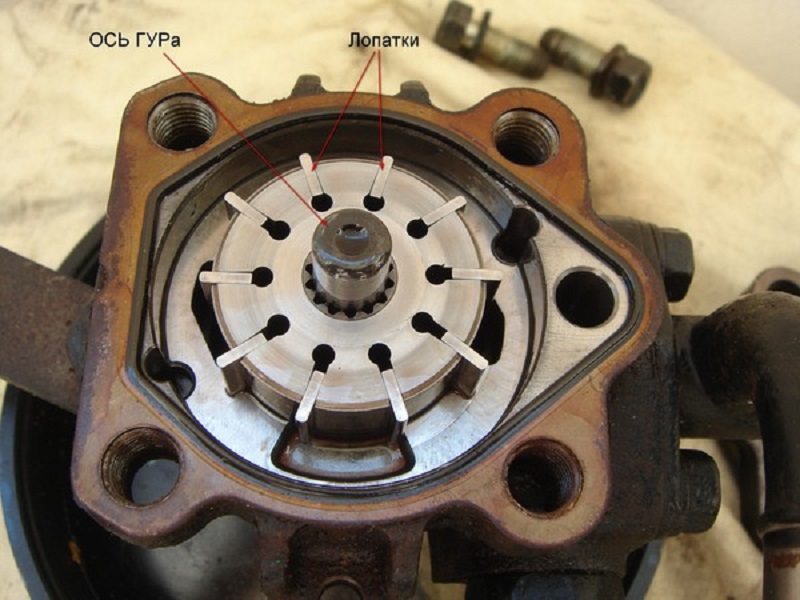

The most common type of pump is blade, as a rule, a plate, providing a large efficiency and high wear resistance. But it has a weak link - the bearing, as a result of which he has to repair it. Pressure in such pumps is very high - 150 bar.

Causes of the failure of the pump GUR

- Possible overheating of the hydraulic unit and the absence of fluid movement.

- Foreign impurities hit the system.

- Lowering the liquid level in pipelines and a tank, fluid leakage.

- The working fluid does not change for a long time, and the material is used that does not correspond to the recommended unit.

Signs of failure of the pump GUR

- There is a whistle bearing. If you dismort the belt and swipe the pump shaft, the backlash is detected.

- Specific spots on the elements of the motor or road canvase, the leakage of the working fluid is found.

- During the rotation of the steering shaft, an unpleasant sound appears.

- At idle or small revolutions on the steering wheel, elevated, compared to the usual ride, efforts in the process of rotation of the wheels appear. With increasing revolutions of the power unit, efforts disappear.

Remkomplekt pump GUR, which is included in the kit, where to purchase it

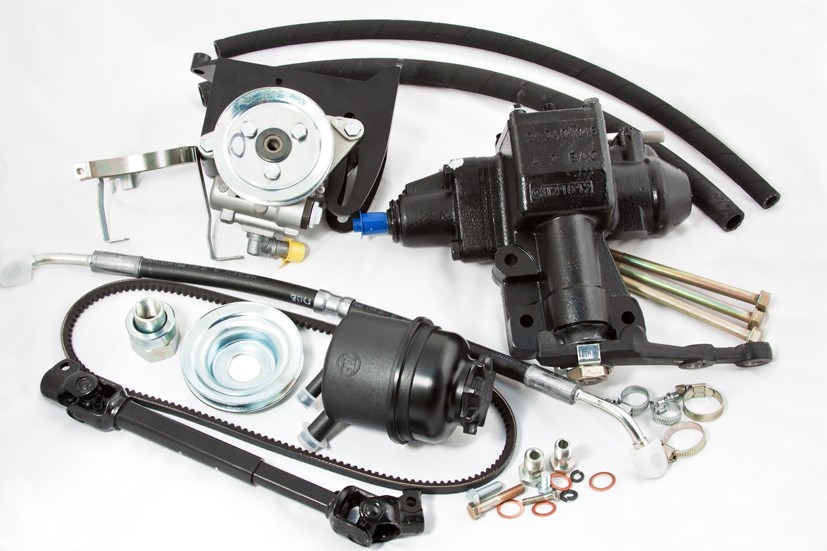

The following elements include two sealing rings, two copper washers, gland and gasket for rear casing. You can buy it in any auto shop.

Preparation of workplace

Repair the pump GUR follows in the garage or another room in which there is a workbench that needs to be cleaned and covered with cardboard is necessary for disassembling the pump.

Tools, fixtures, consumables

- Small sandpaper.

- Ribs for wiping.

- Capacity.

- Big syringe.

- Bearing with an external 35 mm diameter and "6202" marking.

- Remkomplekt.

- Puller for locking rings.

- Heads on "24" and "14".

- The key to "12".

How to remove the pump gur, step by step

- Slightly release the axial bolt fastening the pump unit using a hole that is available in the pulley. Fully unscrew the tensioner lock and dismantle the belt.

- With the help of a syringe, throw out the hydraulic fluid from the tank. Turn the steering wheel left-to the right until it stops until the oil is completely out of the system.

- Loosen the clamp on the hose, which goes from the expansion tank, and remove this pipeline.

- Unscrew the bolt fixing the high pressure hose, which comes from the pump unit into the system.

- Remove the axial bolt that locks the pump to the bracket, then insert a screwdriver or a metal rod instead, which is suitable in diameter. It is necessary to stall the pulley. Then unscrew the nut fastening the pump pulley.

- Pull the released hydraulic power pump.

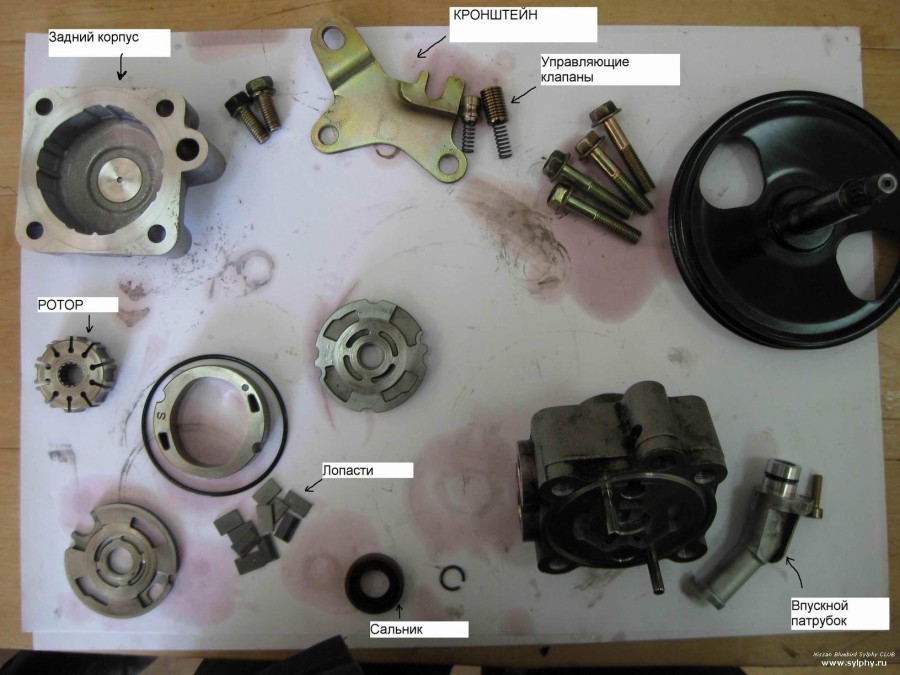

How to remove the bearing, detail

- When the pump is removed, put it on a pre-prepared place. Remove oil and dirt from the unit housing.

- Taking advantage of the puller, remove the retaining ring of the bearing.

- Unscrew the bolts securing the back cover. Carefully find it with a small screwdriver and remove. It is necessary to do so carefully, to avoid dropping from the housing of the rotor blades.

- Pull the blades and put on numbered papers that need to be prepared in advance so that when assembling nothing to confuse. It is important to remember the location of the blades, when installing, their rounded part must be wrapped out.

- Remove the plate and all the items that are under it.

- Carefully tapping a screwdriver, bulk the shaft.

- Press the bearing pump from the pump.

How to check and clean the details of the pump GUR

Check the pump elements for wear and defects. Clean the surface from pollution and roughness. Professionals argue that the usual cleaning of internal elements reduces the gaps and makes it possible to extend the operation of this unit without resorting to the replacement of some parts.

How to assemble the pump gur step by step

The assembly is carried out in reverse order. It is mandatory to replace the gland, sealing rings and the washers to new, prepared in advance.

When and how to change the pump GUR to a new

If for some reason you cannot independently repair the hydraulic power supply pump, you should replace it. To do this, dismantle the pump GUR according to the scheme described above and install a new one.

Tips Prof.

Of course, it is better to see once than to hear ten times, so it is desirable to watch the video on this topic.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments