On time, the observed and eliminated problem will allow you to save the owner of the vehicle from many problems, including from sudden damage at the most inopportune moment and later expensive repairs. In addition, high-quality spare parts installed on the car will significantly increase its life without possible damage.

Content

- The main clutch cylinder, where installed and how it works

- Construction of the main clutch cylinder

- Signs and Causes of Malfunction of the Main Cylinder Clutch

- How to purchase a high-quality clutch cylinder, to pay attention to

- Tools, fixtures, consumables

- How to dismantle the old clutch cylinder and how to install a new clutch cylinder (step by step)

- Leakage of connections when replacing, than threatens the car

- Possible faults of the main clutch cylinder and how to eliminate them

- Repair kit for repair of the main clutch cylinder from what it consists

- Removelectheck installation with your own hands (step by step)

- Reliable spare parts manufacturers of the main clutch cylinder

- Tips Prof.

The main clutch cylinder, where installed and how it works

Many car owners, looking under the hood of their car, pay attention only to visible problems that can independently discern, evaluate and give a preliminary conclusion. The level of automotive oil in the engine and its condition, the presence of coolant in the system, the presence of brake fluid, etc. This is what can visually identify even the most inexperienced driver. Also very often, car owners assess the condition of their car according to the presence of different lects of liquids and the presence of mechanical damage.

In order for the car to be in motion, there must be a correct interaction between the work of the "heart" of the machine - its motor and chassis. It is the clutch that allows you to temporarily disconnect with the power transmission of the engine crankshaft. This makes it possible to calmly switch gear inside the gearbox. Also, the clutch functions are used during partial braking of the car with its full stop.

One of the most important elements in this system that performs all of the above functions is the main clutch cylinder. Knowledge of its location, basic functions and possible faults will give the opportunity to independently diagnose the malfunction and work to eliminate.

Alone to determine the location of the main cylinder of the car clutch is quite simple - it is almost in all ground vehicles, it is immediately behind the clutch pedal, or between the gearbox and the engine, depending on the brand and model. While pressing the pedal, the clutch is turned off and the operating engine is disconnected from the gearbox. After the clutch pedal returns to its original position - all connections also become on their places and the power supply of the engine crankshaft is again connected.

Construction of the main clutch cylinder

Despite all its importance in the continuous and proper operation of any car, the design of the main clutch cylinder is quite simple and does not have a large number of parts. This allows in the event of a malfunction of this node quickly and independently diagnose a malfunction, reveal the possible breakdowns and troubleshoot problems.

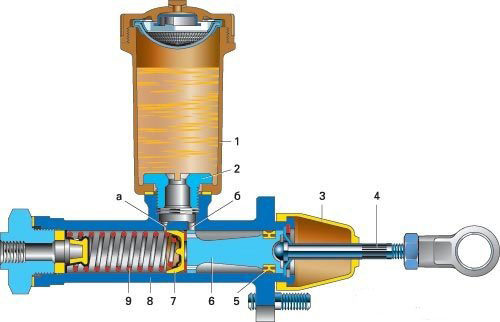

The design of this car detail is very simple and does not require great knowledge in the car mechanic:

1 - a special tank, which can be located both in one design with the main clutch cylinder, and separately from it, supplied through the tubes. The tank serves as a container where the brake fluid is located.

2 - bypass fitting performs the transmission function of overpressure from the system in the tank and back.

3 - Protective cover - does not allow moisture, dust and dirt to the rod of the pusher.

4 - Pusher stock - transmits effort from the clutch pedal (when pressed it) towards the hydraulic drive system.

5 - outer cuff - is the main sealing element, has a round shape and does not allow the output of the brake fluid on the side of the pusher rod.

6 - rod (piston) gives an effort from the pusher further into the system through the springs and discs to the flywheel mechanism.

7 - The inner sealing cuff creates a tightness and is one of the barriers that prevents spontaneous fluid outlet from the clutch system.

8 - The cylinder housing is a reliable and durable part of the main clutch cylinder, inside which all design elements are located.

9 - The return spring allows you to return the rod of the pusher and the inner piston in the initial position after the cessation of the force from the clutch pedal.

Signs and Causes of Malfunction of the Main Cylinder Clutch

A malfunction in this element can lead to very unpleasant consequences, among which is the easiest - discomfort while driving.

In order to independently diagnose malfunctions in the main clutch cylinder, you should understand the device and the principle of its operation. Only after which it can be proceeded to study the health of the cylinder, as well as the definition of any faults.

One of the main types of faults in the clutch system can be determined by a gradual decrease in the level of brake fluid in the tank. Since the hydraulic clutch system is absolutely hermetic, therefore the level of fluid should always be at one level. Otherwise, you should visually seek the reason for the reduction of fluid.

First, all connecting tubes should be examined on the possibility of formation of leakage, after which check all sealing cuffs. In the absence of visible damage in these elements of the clutch system, it is necessary to examine the pusher stock and the main piston of the main cylinder for wear. With constant friction of the piston and pusher about the body, metal parts of the structure can wear out, which subsequently entails the system tightness disorders.

The next cause of clutch problems may be rare or permanent failures of the clutch pedal, which in turn demonstrates the appearance of the breakdown in the system. It happens most often in the investigation of the disruption of the tightness, which burst the hoses or with the complete absence of brake fluid in the tank. This leads to a gradual suction of the air and is one of the most frequent types of faults.

Crunch from KP while switching speeds can be one of the most unpleasant fault species of the clutch system and the main cylinder in particular. On time, the not eliminated this problem can lead to more expensive repair of the car. The same "crunch" can cause possible breakdowns of the return spring in the main cylinder, or a piston malfunction.

Any of the above signs of breakage of the main cylinder of the clutch system must be eliminated as quickly as possible and not delaying with it. Careful inspection and verification of all major elements of the clutch system will significantly reduce the risks of the occurrence of more complex breakdowns. It is worth noting that not in time the eliminated problem can lead both to the gearbox breakdown and the most expensive repairs.

How to purchase a high-quality clutch cylinder, to pay attention to

The first thing to pay attention should be paid when choosing a high-quality clutch cylinder is its cost. Unfortunately, today in the automotive market it is quite difficult to choose high-quality spare parts for the car whose value will be significantly lower than the average selling price. Before you go to the car shop at the new item, it is recommended to explore the market and all possible offers. Only after that, focusing in the proposals boldly go to a more convenient automotive store for the necessary clutch cylinder.

In fact, the acquisition of a high-quality clutch cylinder is a rather difficult task, because it is possible to fully check it only after installation in the car, pumping and testing. However, the selection of the cylinder must be proceeding with visual inspection for visible damage. Clamps should be inspecting that do not allow the brake fluid output from the system. They should be tightly planted and have no visible damage.

Next, it is possible to close as much as possible to press on the rod and see how quickly it will return to the opposite position, after the end of the impact on it. The rod should instantly return to the place, thereby confirming the normal operation of the return spring.

You can also independently check the tightness of the system at low pressure. To do this, close the graduation and intake fittings, through which the brake fluid under the system passes. By pressing re-stem, it should not burn the air from the joints of the design and a hermetic cuff.

On the case itself, there should also be no visible damage - chips, shocks, cracks, dents. Since this part of the car is quite often under the influence of internal pressure when pressed on the clutch pedal.

Tools, fixtures, consumables

When repairing or replacing the main clutch cylinder, elementary knowledge of its device is needed, as well as location. During the work themselves, at their disposal a small set of tools and often the cross screwdriver and a wrench can be enough. This will be enough for self-dismantling of the cylinder, eliminate possible faults or its complete replacement, as well as installations in place.

Additional tools that will be needed for repair work can become dry and clean rag, syringe, container for the brake fluid fusion, as well as a long hose, the diameter of which will allow you to wear tightly on the air valve.

From the consumables immediately should take care of the acquisition of the brake fluid of the same brand, which was filled before. In the absence of information about the old liquid, it is necessary to purchase an additional special flushing, which will avoid possible trouble due to their incompatibility.

How to dismantle the old clutch cylinder and how to install a new clutch cylinder (step by step)

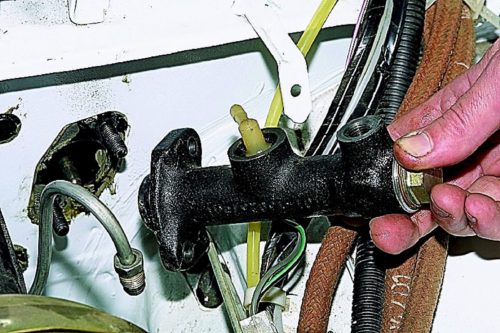

First of all, unscrew the tank cover with the brake fluid, remove the rubber gasket, which prevents the air in the system and creates overpressure. After that, with the help of a syringe, it should be removed the entire brake fluid in it, which will avoid splashing it during the removal of the cylinder. At the second stage, it is necessary to determine the place in which the clutch pedal is attached to the main cylinder. The process itself is very difficult because it is very difficult to get to this place. It is always more often in the car's cabin in a place where the cylinder goes into the engine compartment.

Pre-prepare special plugs, with which it will be possible to clog hoses with fluid flowing from them. Now you should disconnect the hoses from the fittings and unscrew the tubes from the cylinder, after which all hoses should be dried.

Next, you need to unscrew the nuts, with which the main clutch cylinder is attached to the car body. The process is easy, but not very convenient to operate a wrench. After this stage, we take out the old brake cylinder and install a new one in its place. Installing and connecting it is carried out in the reverse order of dismantling.

When the new main clutch cylinder is in its place and all hoses are connected, it is necessary to pour the brake fluid into the clutch tank and proceed to pumping the system.

Pumping begins with the fact that the hose is selected, which are tightly dressed on the air valve. The valve is on the clutch working cylinder, and the reverse end is lowered into a predetermined container. Using a suitable key, the valve is unscrewed and the pumping process itself begins.

The process of pumping is carried out by two people, one of which will be under a motor compartment, the second - on the driver's seat. A man in the cabin of the car several times to the end presses the clutch pedal and holds it down. At this point, the second mechanic for several revolutions unscrews the valve and allows you to exit the fluid from the system and looks at the presence of air bubbles. After that, the procedure is repeated several times until the air bubbles stop leaving the system.

Periodically, it is necessary to check the level of fluid in the tank and prevent its complete flowing. Such a relatively simple procedure is the replacement of the main cylinder of the car clutch.

Leakage of connections when replacing, than threatens the car

The clutch system itself should be absolutely hermetic, which allows it to function normally and have no failures. However, it often happens that the car owner is simply neglecting the periodic maintenance of its vehicle and misses the moment when it should be repaired or replacing individual parts of the design.

Also, the tightness of the system can be violated due to the incorrect replacement / repair of the clutch cylinder, or in case of installation of a deliberately poor-quality part.

The gradual leakage of the compounds when replacing the clutch cylinder leads to the flow of hydraulic fluid from the system and suction. This occurs during pressing the press of the clutch pedal when an additional pressure of the hydraulic fluid is created in the system. Even the slightest air bubble, which fell into a leakage system can lead to the fact that the failures in the clutch work appear. The pedal move becomes softer, and the clutch itself becomes less effective - a crunch appears, the speed is more complex. On time, the wrong problem will be able to lead not only to not comfortable driving, because it will have to squeeze the clutch pedal several times to switch the speed, but also to the possible failure of the entire gearbox.

With a leaning system, the parts transmitting torque from the engine on the required shaft of the gearbox can fail.

Possible faults of the main clutch cylinder and how to eliminate them

The main cylinder clutch allows you to significantly reduce the degree of impact on the release bearing and improve the smoothness of the pedal stroke and switching transmission. However, when any malfunctions appear in the work of the main clutch cylinder, it begins to perform its functions much worse.

Only 3 main cylinder malfunctions can be distinguished:

- mechanical wear of individual structural elements;

- enforcement of the clutch system;

- reducing the level of hydraulic fluid in the system.

In case of depressurization of the clutch system and entering it, this can lead to a nuisance that will affect normal operation. This may occur as a result of entering the air system through small cracks in connecting tubes and hoses, as well as sealing rings.

In time, the problem did not find the most inappropriate moment to lead to partial or complete output of the entire clutch system. In order to correct this situation, a visual inspection of all connecting elements should be made, as well as their joints, then make the replacement of problem areas, after which it is to pump the hydraulic system. Such a malfunction is made quite easily and does not require any special equipment and high level of knowledge. Most of the car owners are perfectly versed in pumping both the brake system and the clutch system.

In the case when the level of the hydraulic fluid in the system is constantly decreasing, it should be more carefully examined the entire system for possible mechanical damage through which the brakesuch comes out. The absence of fluid in the systems will not allow creating the necessary pressure to transmit effort from the clutch pedal to the release bearing. Thus, the driver of the car simply will not be able to disconnect the engine and gearbox.

The problem with depressurization can be as a result of the breakage of the connecting tubes and hoses, as well as the wear of the movable elements of the main clutch cylinder. To solve problems with leakage through the connecting elements, it will take some time to completely replace them. If the problem was detected in the cylinder, it should be dismantled, examine the possibility of damage and decide on its full replacement, or using Remkomplekt.

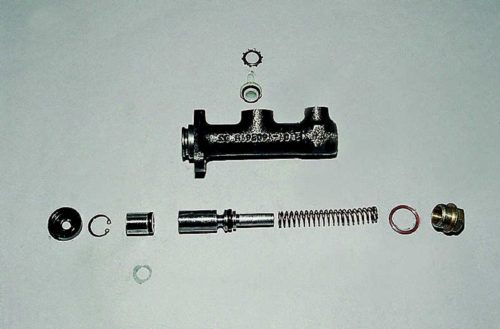

Repair kit for repair of the main clutch cylinder from what it consists

In essence, Remkomplekt is a set of details most necessary for the repair of a certain assembly of the car unit.

The most common remkomplekt for the repair of the main clutch cylinder consists of 4 parts. The set contains 1 protective cap, 2 pcs. Rear brake pressure regulator piston sealing heads, one clutch shock hose hose cap. By buying such a set, every car owner will be able to not only save a certain amount of personal funds for the purchase of a new cylinder, but also return the performance of this vehicle.

Removelectheck installation with your own hands (step by step)

At the first stage, it is sorting out how to remove the cylinder from the car. Most often, this item is directly immediately behind the clutch pedal and does not require special skills to dismantle it. However, learning the design of the car still follows.

After the cylinder is determined with the location of the cylinder, you should disconnect all hoses and tubes that are suitable for it, and then unscrew them and shut up using special plugs. This will save the system from the leakage of a large amount of hydraulic fluid. Next, the cylinder itself is unscrewed from the car body and so it is dismantled. It should be carefully taken to disassemble the main cylinder, so as not to apply additional damage. And despite the minimum number of parts of which the cylinder consists, it is recommended that the minimum experience of the car repair work is recommended.

During dismantling and disassembling this part of the car, it is recommended to memorize each operation produced, because the assembly will occur exactly in the reverse order. It is also recommended to record phased work, or to make step-by-step photographs of the whole process. It will save from possible errors.

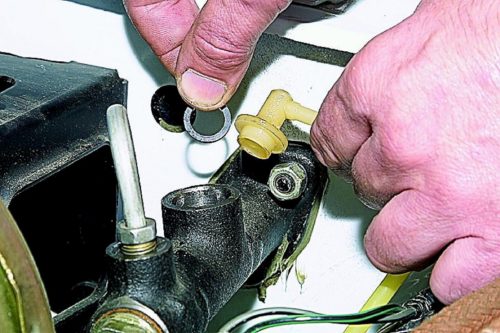

When the cylinder is completely removed from the car, it must be carefully disassembled and it is recommended to do it on a bright and clean workplace. To do this, it is necessary to unscrew the locking bolt in its front part, after which it is necessary to pull out all the details and rinse them thoroughly with the help of brake fluid. Use of any other liquids - gasoline, acetone, solvent, etc., is strictly prohibited. Rinse in the brake is needed and all parts from Remkomplekt before they are replaced.

When the main cylinder is completely disassembled, you can safely begin to visual inspection of the state of all parts that have already been washed in the brake fluid and dried. At first, the piston, the pusher and the inner walls of the cylinder should be inspecting. Since they are most often formed by corrosion. To eliminate such a problem, it is thoroughly, but carefully clean the finely emotional paper. However, if the corrosion surface left deep damage, it is recommended to think about the complete replacement of individual parts of the structure or the entire cylinder. As this may soon manifest itself as a disorder of the hydraulic system sealing.

Next, all the sealing parts of the cylinder should be inspecting, in the case of the detection of any miniature damage, you need a mandatory replacement for parts from Remkomplekt. Even if the smallest damage is visually noticeable, they can pass the hydraulic fluid at the slightest increase in pressure.

When all parts from Remkomplekt were installed instead of worked, it is necessary to install the main cylinder of the clutch in the reverse order of its removal. Next pumps the system in order to avoid its delight.

Reliable spare parts manufacturers of the main clutch cylinder

Producers from Spain, Italy, Germany, Great Britain are popular with popularity. Choose the optimal version of reliable manufacturers is quite difficult, as some of them specialize only on certain brands of cars.

In Spain, the most popular manufacturers are Autofren Seinsa, in Italy - LRP, Brembo, in Germany - Sachs, TRW, FTE. However, despite such an abundance of the most popular manufacturer, for our car owners is Feredo (United Kingdom). This company produces a huge number of spare parts for different car brands.

Tips Prof.

The main clutch cylinder is one of the most important elements of any modern car. For this part of the car, it is also recommended to closely, as well as at the work of other important organs of the car. A normally functioning cylinder will save the owner of the motor vehicle from unpleasant situations on the road, such as the failure of the clutch pedals, poorly switched transmission, or the full failure of the entire system.

The chief advice is not to leave any problem that has arisen easily and use only proven spare parts from well-known global manufacturers.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments