PPC VAZ 2109 is quite "leaving" with their own hands. Of course, provided that the "garage master" has the necessary experience and skills, as well as tools and equipment, otherwise you can only aggravate the situation. If you have never previously repaired the gearbox, it is better to contact the pro, or at least read this material to the end.

Content

- PPC VAZ 2109 Device and action principle

- Signs of faults PPC VAZ2109

- Possible causes of damage gearbox VAZ 2109

- How to eliminate faults PPC VAZ 2109

- Picking gear with your own hands

- The service life of the PPC VAZ 2109, when the replacement of the CAT

- Which oil is poured into the PPC VAZ 2109, the advice of the pro

PPC VAZ 2109 Device and action principle

A box of nine is a complex unit designed to change the torque that is served on the wheels of the car, as, however, and any other checkpoint.

Specifically about the unit installed on "nines", we can say the following:

• PPC may be four and five-speed.

• The entire system is combined with the main transmission, as well as with differential, so the number of gears can be different.

• Primary shaft is, in fact, a set of leading gears, they engage for the driven gears of the front turn.

• Torque with the CAT is transmitted to the front wheels of the car.

This is what concerns the main indicators of the CAT, thanks to which the device turned out to be quite reliable and durable.

The main elements of the VAZ 2109 box:

• Carter.

• Two synchronizer.

• Primary and secondary shafts.

• Axis and reverse gear.

• Main gear.

• Differential.

• Case cover.

The gearbox flange is connected to the gearbox of the main transmission device. The KPP 2109 drive is as follows:

• The transmitting torque switch.

• Spherical bearing.

• Tract.

• Speed \u200b\u200bswitch lever.

• Rod working as a gear shift mechanism.

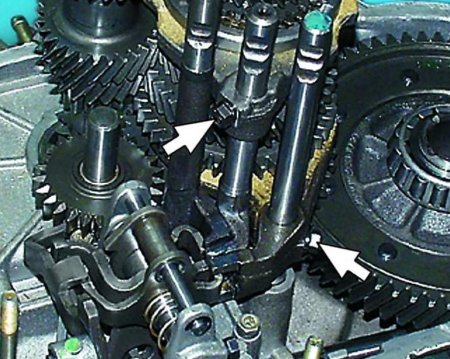

All of the above elements are a separate node that is attached to the clutch. Inside the gearbox are two axes. One of them is installed: two blocking brackets, a three-way lever and a sleeve - to increase the reliability of the device. The second axis passes through special holes in blocking brackets, preventing their turning.

Purpose of shoulder levers:

• The first shoulder includes front transmissions.

• Second shoulder - reverse.

• The third shoulder is intended to interact with the switching lever of transmitting elements.

• Lever switch hub has a special retainer.

• A plug is fixed on the axis to turn on the rear speed.

Signs of faults PPC VAZ2109

The most common "symptoms" of the gearbox faults "Nine" is as follows:

• Transmission turns off on their own.

• Noise box when working on neutral transmission.

• The speed turns on with a crunch, the inclusion of the transfer is difficult.

• The transmission turns on fuzzy.

• The backlash gearboxes - the switch lever is chatting.

• "Ring" Kulis.

• Oil level falls.

Possible causes of damage gearbox VAZ 2109

Like any other device, the gearbox "Nine" eventually begins to fail. A considerable role at the same time also plays the quality of spare parts that are used during repair. If you adhere to the manufacturer's recommendations, then the repair of the CAT (including prophylactic, in the absence of breakdowns) should be made every 50,000 km. Consider the main causes of the breakdown of the gearbox, respectively, listed above "Symptoms":

"Careful Transfer"

Most likely, the gearbox is strongly worn out. Castle wear on a coupling or gear, these parts will be replaced. The main reason is a systematic violation of the rules of operation, incorrect selection of speed mode, too sharp switching, incorrectly adjusted grip.

noise box when working on neutral transmission

Any gearbox has a certain threshold of noise, which cannot be a damage indicator, no box works absolutely silently. Increased noise level may indicate the need to replace oil in a box or its insufficient level. In addition, noise may increase when the engine is unstable. For example, if a sports camshaft was installed on the car, and the PPC is not included in the resonance with it.

For more accurate diagnostics, it is recommended to take on the nearest service station, since the box can make noise for a variety of reasons, including those not related to the PPC itself.

transmission turns on with a crunch, the inclusion of the transfer is difficult

If the PPC has a decent mileage, then the reason is most likely in the wear of the synchronizer. It must be replaced urgently, since the situation is fraught with the failure of the entire gear unit. When the box is new, or the synchronizer has recently changed, then the transmissions can also turn on tight - this is normal.

transmission turns on fuzzy, inclusion requires effort

Difficulties when switching on the transmission can be explained, as mentioned above, the synchronizer is replaced. Over time, the details are being developed and switching is done without effort. Immediately after replacing the synchronizer, it is not recommended to sharply enable transmissions, withstand small pauses when switching. The transfer still did not turn on - use double out. If the transmission is switched on unfortunately, this may indicate a malfunction in the transmission selection mechanism as well as improperly adjusting the scenes, or its supports. To accurately determine the reason, the scenes are needed.

gesther gearboxes - Switching lever

First, check the condition of the "cardanchik" (KPP hinge). Very often, the luft is the cone bolt of fastening that can be unwound.

The backlash may occur in the cooled itself as a result of its wear. In this case, it is necessary to replace the Kulis. In addition, a return spring can burst. This item is in the gear selection mechanism - it will be necessary to repair the gearbox with the springs replacement.

"Ring" Kulis

It should be noted that this is a very common drawback of all domestic cars, very often arising after repairing the chassis. Sometimes it happens on the contrary - after repairing clashing disappears (if he took place on a new car). The reason may be in the factory defect, which is recognized even representatives of AvtoVAZ.

In addition, the reason may conclude in the vibration of the engine + box, which is transmitted to the scene. The ringing can be associated with a car body or an incorrect choice of support points. In such cases, attempts are being made to eliminate ringing by installing a sealing ring near the scenes (relevant only for VAZ 2108-2115).

oil leakage from box

Possible causes are a bad fastening of the crankcase cover, loss of tightness of the shafts. In addition, you may need to replace the boxes of the box or tritely spin the drain plug. It does not interfere also to inspect the CAT hull for damage and cracks.

How to eliminate faults PPC VAZ 2109

So, above, we listed the main fault of the PPC VAZ 2109, how to determine the fault and how to fix it, we will tell below.

it is difficult to turn on the transfer

Cause:

1. Error when adjusting the clutch.

2. Hold the cable or drive drive.

3. Hold the fork rod, speed switching rod.

4. One of the details of the checkpoint: fork, slider, synchronizer.

5. Non-centered clutch crankcase.

6. Maslo is chosen incorrectly.

7. Instructed blocking rings of the synchronizer. The conical surfaces of the slave gears extended.

Solution:

1. Adjust the clutch.

2. Determine the cause, lubricate.

3. Check the lever hinge fastening. Check whether the bolts on the control mechanism are tightly tightened. Be sure to explore the rods, as well as the holes of the rods in the crankcase, the glands, the rear section of the crankcase. All identified faults - repair.

4. Disassemble the box, inspect the details. Worn or damaged - replace.

5. Disassemble, check the checkpoint. Worn parts replace items.

6. Replace oil

7. Check the gap between the gear teeth and the blocking ring. If everything is fine, then the gap should be at least 0.77 mm. If the clearance is normal, check the conical planes of the blocking ring and gear.

crushing when switching

Cause:

1. The clutch is incorrectly adjusted.

2. Lands or drive cable.

3. Incanticized clutch crankcase.

4. Fell the oil level or oil is incorrectly selected.

5. Was worn or failed to switch the gear or synchronizer.

Solution:

1. Adjust the clutch.

2. Lubricate the cable or traction, eliminate faults.

3. Check the mounting of the holes in the back of the crankcase.

4. Replace or add oil, check the availability of leaks.

5. Disassemble the PPC, check the items if necessary.

elevated noise level

Problem:

1. Carter bolts, gearbox or clutch are unscrewed.

2. Inside the checkpoint hit foreign particles.

3. I wear out or damaged the internal parts of the CAT.

4. Non-centered clutch.

Solution:

1. Check bots, if necessary, tighten

2. Fully drain the oil, wash the crankcase thoroughly, change the oil.

3. Remove and disassemble the box, check the items damaged to replace.

4. Check the centering of the holes in the rear of the clutch (on the crankcase).

translations "fly out"

Problem:

1. Weared to fasten the gear lever.

2. Failed the liner of the scenes or weakened the nut scenes.

3. The primary shaft of the box or roller bearing was worn out.

4. I wear out or failed one of the elements of the gear mechanism - a fork, slider, coupling, a fixator, etc. Perhaps the lid is damaged.

5. The gear or synchronizer's teeth were worn out or failed, resistant washers or driven gears of the secondary shaft were damaged.

6. Fastered the bushing of the guide bearing.

Solution:

1. Check the wear attachment, pull the fasteners if they weakened.

2. Remove the gear lever, inspect the nylon liner of the scenes, pull the nut or replace the liner.

3. Disassemble the CAT, replace the primary shaft or, if necessary, the roller bearing.

4. Remove the top cover of the box, check the details of the switching mechanism. Damaged details replace.

5. To completely remove the box, disassemble, inspect, if necessary, replace damaged parts.

6. Change the guide bearing sleeve.

it does not turn off one of the gears

Cause:

1. Distressed or failed stocks (rod), weakening the screw slider, weakened the spring of the average retainer.

2. The teeth of the gear of the intermediate, primary shaft or the shaft of the rear speed gear were extended.

3. The gearshift lever itself or one of the details of the switching mechanism are faced.

Solution:

1. Check the items, replace broken.

2. Remove and disassemble the checkpoint, if necessary, install new details.

3. Check the lever status, eliminate malfunctions, remove the gearbox, check the gear shift mechanism.

Picking gear with your own hands

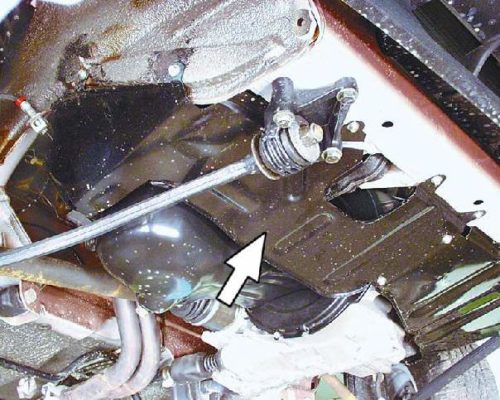

Dismantling box must be made in the observation pit on the overpass or on the lift.

To remove and disassemble the VAZ 2109 box, the following tools, fixtures and consumables will be needed:

• Screwdriwer set.

• Rubber and metal hammers.

• Impact screwdriver (required).

• Chisel.

• Set of cape heads with "cracks".

• The key designed to remove locking rings.

• Clean rags.

• Sandpaper.

• gasoline, solvent (to wash the case after dismantling).

• Butter.

• Gaskets.

The choice of the workplace depends only on the convenience and personal preferences. A good option is a wide strong table (workbench). All manipulations can be done on the smooth floor, although it is not entirely convenient. In general, everything you need to work is a clean smooth surface and good tools.

dismantling gear

• First of all, all the oil is drained from the box.

• Remove the bolts that are fixing the crankcase protection.

• Turn off the clutch wire from the clutch.

• Weaken the nut on the drive cable tip.

• Turn off the block from the traction relay.

• Disconnect drive thrust from the hinge tip (speed traction).

• Disconnect the speedometer cable.

• Remove the fastening of the ball hinge steering thrust.

• Next should be pressed the finger of the hinge steering thrust from the rack lever.

• Suggest the shank of the wheel drive shrus and assign it a bit to the side.

• Disconnect the second ball support.

• We dismantle the clutch crankcase shield.

• We will weaken fasteners, remove the box.

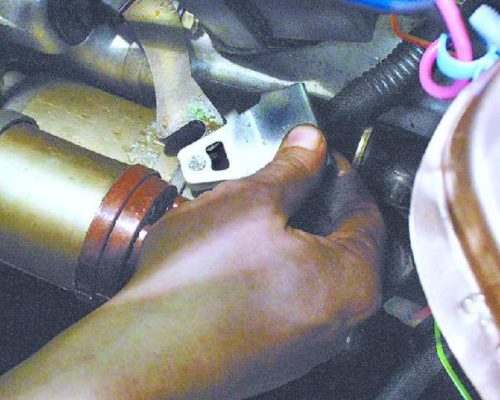

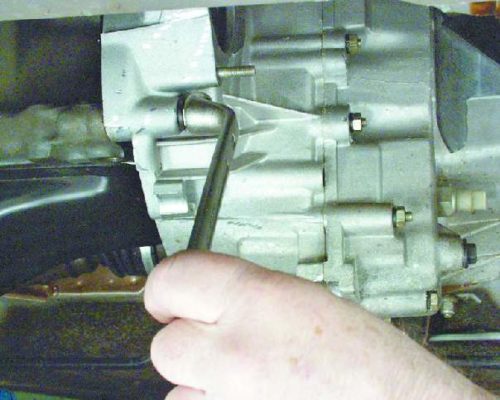

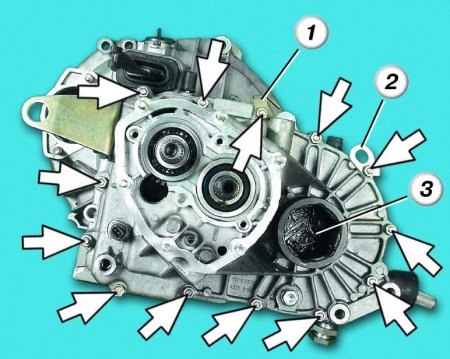

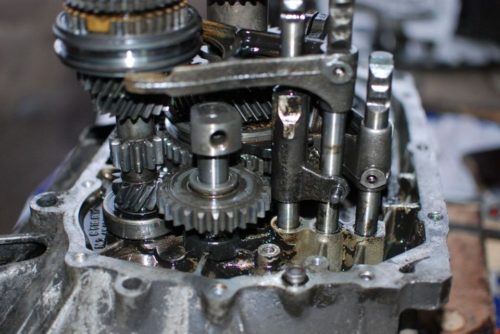

disassembly boxes

To begin, it is necessary to clean the surface of the box from dirt and oil, after which it is washed with solvent, gasoline or kerosene.

• Install the box vertically and gently remove the back cover.

• Remove the clutch cable bracket, after that rubber hammer run the back cover of the box.

• Remove the old gasket. It can be thrown away.

• Turn on 3 and 4 transmission.

• Remove the bot that holds 5 transmission, turn it on.

• We unscrew the nut first on the secondary shaft, then on the primary one.

• Remove the transmission synchronizer 5 with a fork.

• Take the plug from the coupling. At the same time, follow the spring-loaded balls that hold the synchronizer, did not fall.

• Remove the transmission synchronizer block 5 ring.

• Give the driven gear 5 speeds from the secondary shaft.

• We dismantle a stubborn ring of needle bearing, get the bearing itself.

• We dismantle the leading gear of the primary shaft.

• From the secondary shaft, we remove the sleeves that remain from the needle bearing, dismantle the stubborn puck.

• Give the fixing ring of the primary shaft bearing, then remove the ring from the secondary shaft.

• We unscrew the locking cork, remove the ball and spring.

• We dismantle the rear engine support.

• We unscrew the rear transmission lock (plug), slightly tilted the box housing and get the bulb of the lock and the spring.

• We relax and completely unscrew the clutch crankcase bolts, as well as crankcase boxes.

• Disconnect the gearbox.

• We unscrew the bolt to which 1 and 2 transmissions are attached.

• We dismantle the rod and plug.

• Remove the fastening bolt 1 and 2 transmissions.

• Hold off the rod head from the lever, then remove it from the boxes together with the fork.

In the process of disassembling the checkpoint, carefully study all the elements. If it is possible to detect the wear part in time, it can be replaced immediately, thus avoiding expensive repair. The assembly of the PPC VAZ 2109 is carried out strictly in the reverse order. At the same time, the gasket must be replaced by a new one.

The service life of the PPC VAZ 2109, when the replacement of the CAT

As practice shows, the service life of the CPP VAZ 2109 depends, in most cases, on operating conditions. With gentle handling, timely repair and oil replacement, the box can work as much as the engine. As a rule, the synchronizers of transmissions are most often the first. They need to be changed immediately to avoid more serious breakdowns. The service life of the CAT also depends on the quality of parts and assembly - the box can "die" and after 350,000 mileage, and after 10,000 - there is no unambiguous answer. In addition, each car owner, with one or another malfunction, decides itself - to repair the checkpoint or change the entire one.

Which oil is poured into the PPC VAZ 2109, the advice of the pro

Choosing oil for "nine" is not particularly experimenting, it is enough to read the car operating manual. You can also ask the opinion of the owners of this brand, which are very much. As for the recommendation of the plant, the manufacturer recommends using mineral all-season stamps:

Rexol T - SAE 80W-85 class GL-4.

Omskol Trans P.

Owners TM4 - SAE 80W-90 class GL-4.

The manufacturer's plant almost always flooded in the boxes of Mineral oil LUKOIL. It is enough for the first time. However, for operation in winter it is not very suitable, so after purchase it is recommended to replace the oil to any of those listed above.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments