The steering power steering is installed on the steering column in fact of each modern car and is designed to facilitate the control of the vehicle. One of the key elements of this mechanism is a pump that pumps hydraulic fluid through the hydraulic system. In the course of operation, it is subjected to huge loads, so from time to time the need arises to repair the pump GUR. About this further in the article.

Content

- GUR - design, why need gur

- What is the component of Gora most often fail

- Pump gur device and destination

- Types of pumps gur.

- Pump GUR, the causes of the outlet of the pump

- Pump gur, probable malfunctions

- Signs of failure of the pump GUR

- How to pump gur if there is an air traffic jam

- Tools, fixtures, consumables

- Spare parts for repairing pump GUR

- Choosing a workplace

- Pump repair GUR (step-by-step instruction)

- Tips Prof.

- How to find and order a pump Gur and gaskets, auto parts at a table price and free shipping

GUR - design, why need gur

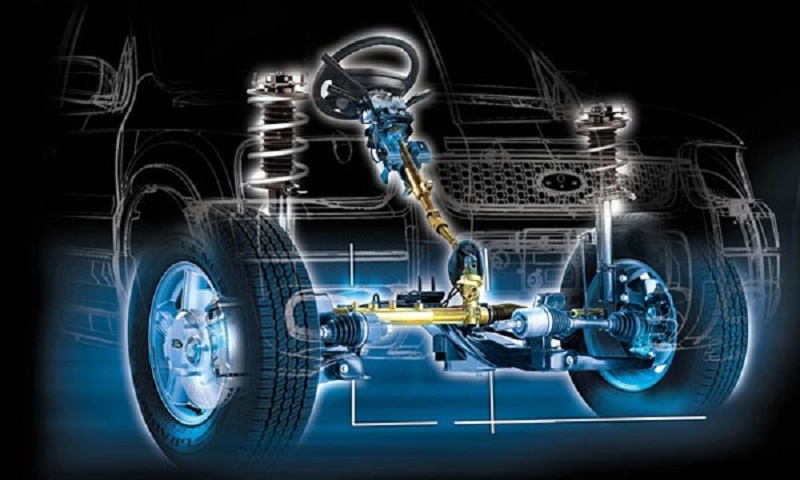

The steering wheel hydraulicer is designed to facilitate the car control of the car during maneuvers on the roadway, and to mitigate the blows from the damaged road surface and irregularities. It is especially important that this device significantly reduces the risk of an accident at a tire break, first of all it concerns the front wheels.

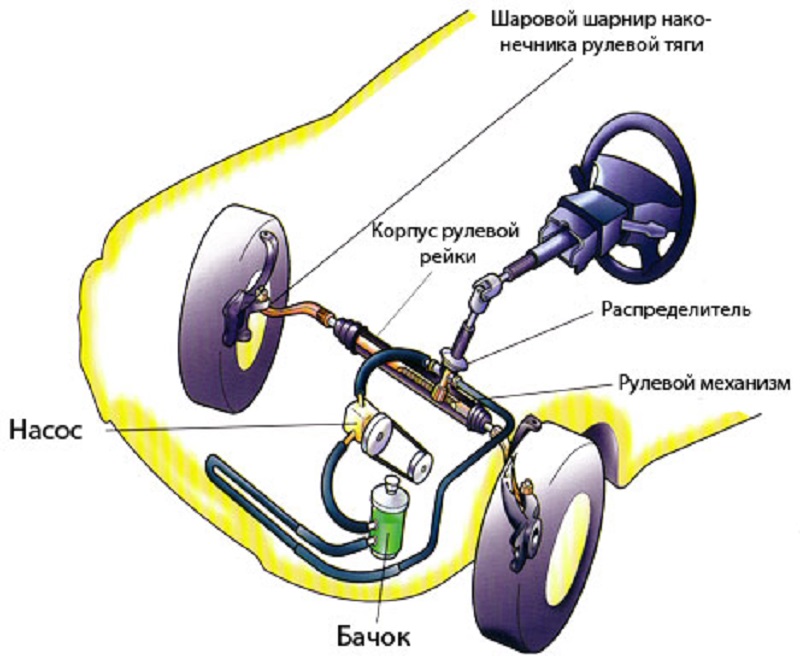

The hydraulic power steering is a closed hydraulic system that consists of:

- The tank in which the hydraulic fluid is refilled.

- Pump.

- Pressure regulator.

- Managing spool.

- Power cylinder.

What is the component of Gora most often fail

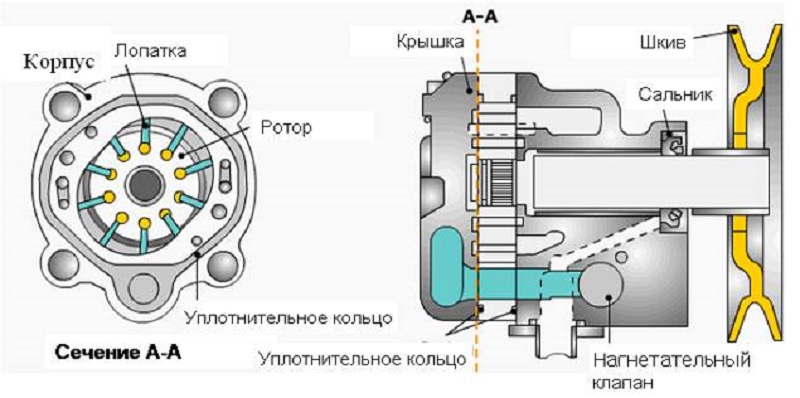

The main unit of the structure of the hydraulicer is the pump that provides the pumping of the liquid from the tank to the pipelines, as well as its further movement over the ring under high pressure. Type of mechanisms used - Plastic or Sewer units. They are distinguished by a sufficient efficiency of efficiency and small wear of work surfaces. At the same time, they have a weak link - there is a possibility of failure of the bearing, which entails the repair of the pump of the hydraulic agent.

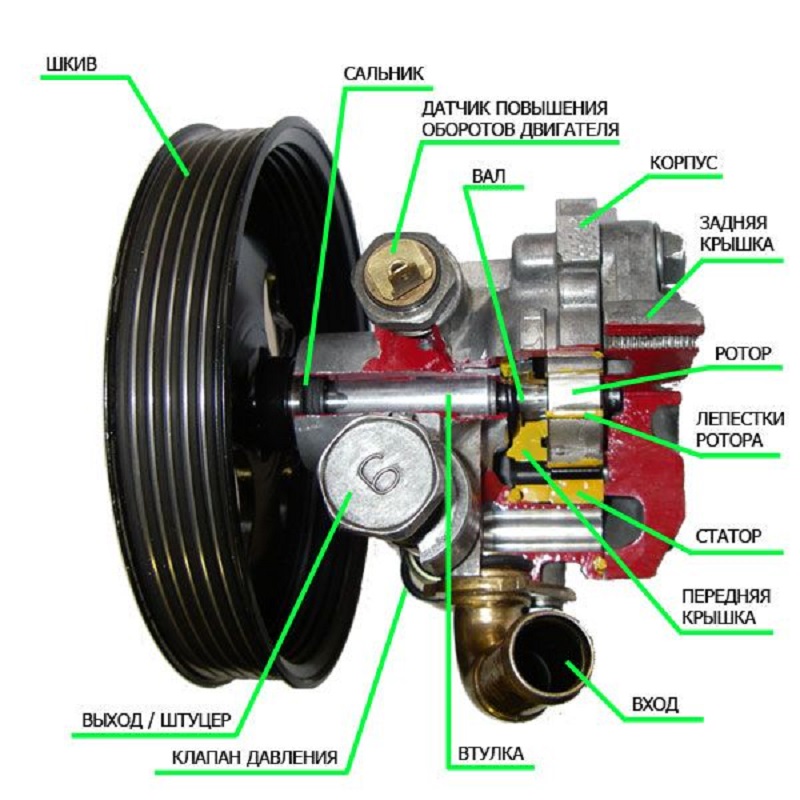

Pump gur device and destination

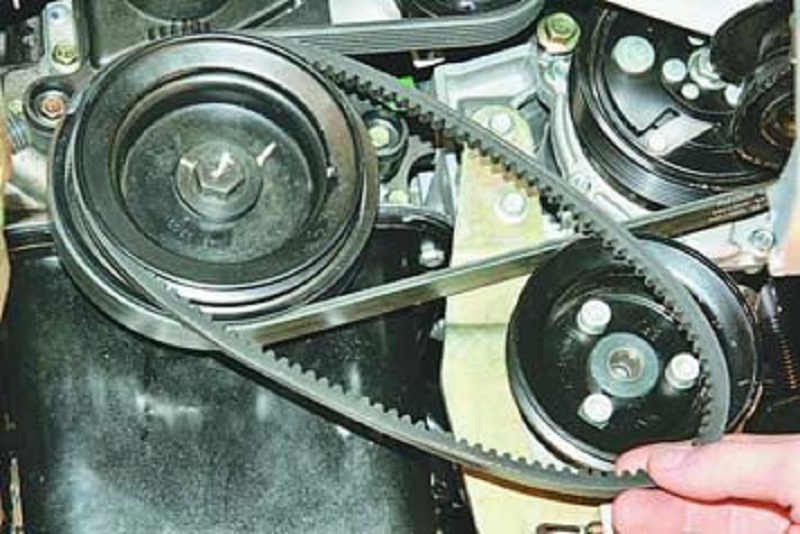

In the pumps of this type intended for the hydraulicel, a sufficiently high working pressure, a maximum of 150 bar. This unit is driven by a belt, which simultaneously turns the pump and the generator. The gaps installed at the factory during the assembly should be saved within 0.005-0.01 millimeters. If the gap increases and exceeds a permissible to 0.01 millimeter, there is a risk of a pressure drop in the system on small revolutions, which is felt on the steering column as an increase in the load or by the language of specialists - "tight" steering wheel.

Types of pumps gur.

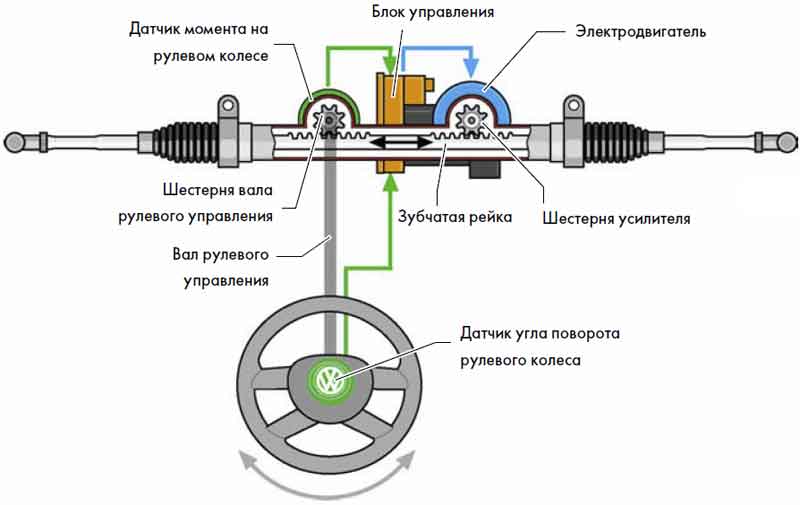

As already mentioned above, there are two types of pumps GUR - Sewberry and lamellar. The lamellar pumps were widely distributed, as they differ from high performance, reliability and ease of maintenance. As a rule, the pump is located on the power unit.

Pump GUR, the causes of the outlet of the pump

The plate unit is considered a durable mechanism, but during its incorrect operation, various emergency cases may occur. The yield of the pump unit is out of order for a number of reasons, namely:

- Falling into the system of extraneous impurities.

- Lack of fluid movement, as well as possible overheating of the hydraulic unit.

- Liquid leak and reduce its level in pipelines and a tank.

- Working fluid for a long time does not change or use the material that does not correspond to the instruction for this unit.

To prevent such a situation, it is necessary to control the fluid level in the tank weekly, as well as check compounds and pipelines for the objects.

Pump gur, probable malfunctions

One of the most common power of the hydraulic fracture is the constant unscrewing pulley. The problem lies in shafts that may well be with certain defects. There is also a risk of a loose contact of the hoses with other components of the system.

Signs of failure of the pump GUR

The yield of the hydraulic pressure pump is defined quite simply. These symptoms are immediately determined by the driver:

- Bearing begins whistle. When swaying the pump shaft and the leaf removed is detected.

- The leakage of fluid is detected according to the characteristic stains on the road surface and the engine elements.

- When rotating the steering wheel, an unpleasant foreign sound appears.

- At idle or small speeds on the steering wheel, elevated, in comparison with the usual ride, efforts during the rotation of the wheels appear.

If such signs occur, the bus owner has to inspect the entire system of the hydraulic agent and decide whether the repair of the hydraulic pressure pump is required, or it is necessary to pay attention to other parts of this design.

How to pump gur if there is an air traffic jam

Before carrying out repair work, it is necessary to test the presence of fluid in the tank, as well as the compliance of the brand of working fluid allowed to use on this car. It is not rarely the reason for the appearance of malfunction symptoms, there is an occurrence in the system of air traffic jams, to remove which it is necessary to pump hydraulics. In this case, the performance of the GUR will be fully restored.

To remove air traffic jams, run the power unit, open the lid of the expansion tank and pump the system, turning the steering wheel several times from one extreme position to another. As the system is pumping, the fluid level in the tank will decrease. The procedure must be repeated until the fluid level is fully stabilized. Then decrease the liquid to the required level.

Tools, fixtures, consumables

- The key to "12".

- Heads on "14", "24".

- Puller for locking rings.

- To pump oil from a tank, a container and a large syringe will be required.

- Ribs for wiping.

- Small sandpaper.

Spare parts for repairing pump GUR

- Bearing with labeling "6202" and an external diameter of 35 millimeters.

- Two copper washers, gasket for rear skin, seal, two sealing rings. All this can be replaced with a remak complex of the pump of the hydraulic agent.

Choosing a workplace

The repair of the hydraulic switch pump must be carried out in the garage or any other room, where there is a workbench that should be cleaned and covered with clean cardboard. It is necessary for disassembling the pump unit.

Pump repair GUR (step-by-step instruction)

To dismantle the hydraulic power pump and repair it independently, you need to perform such actions:

- Lightly release the axial bolt, filling the pump to the bracket, applying a hole that is in the pulley. Fully unscrew the locking nut of the tensioner, after which we dismantle the belt.

- Using a syringe, pump the hydraulic fluid from the tank. Turn the steering wheel to right-left until it stops so that the lubrication fluid is completely out of the system. Do it several times until the pipelines are completely cleansing.

- Weaken the clamp on the hose coming from the expansion tank. Then remove this pipeline.

- We unscrew the bolt fastening the high pressure hose, which goes into the system from the pumping unit.

- We take out the axial bolt that crepts to the pump bracket, and insert a screwdriver instead of it or a metal rod, suitable in diameter to put the pulley. Next, we unscrew the nut that crept the pump pulley.

- I pull out the released pump up and put it on a specially prepared place. We remove oil and dirt from the body of the apparatus.

- With the help of the puller we remove the retaining ring of the bearing.

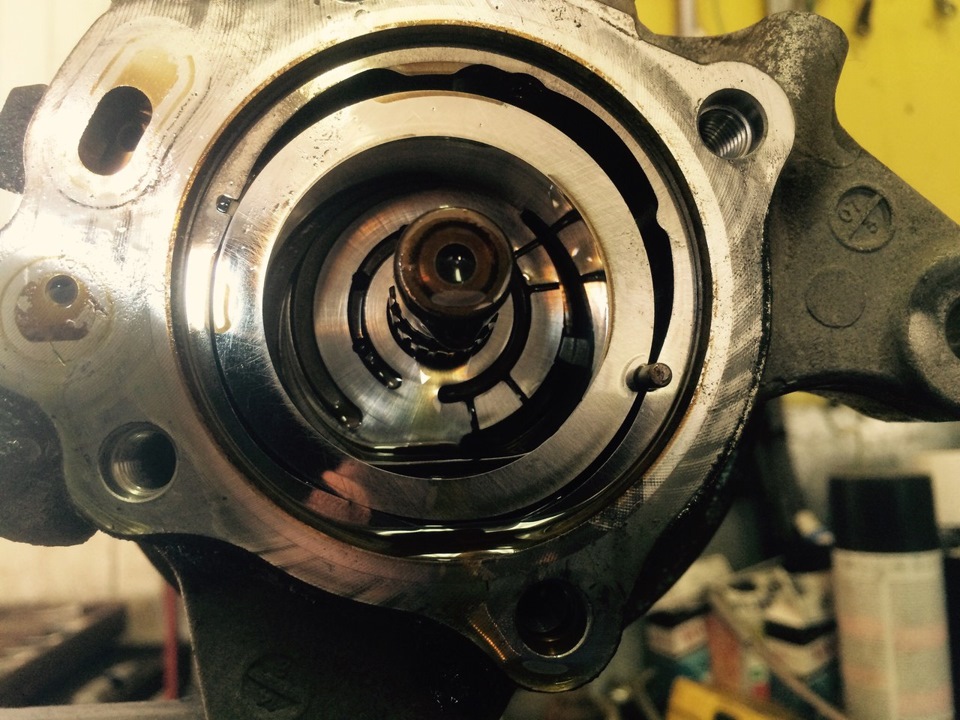

- Remove the rear cover mounting bolts. Gently use it with a small screwdriver and dismantle, controlling that the rotor blades do not fall out of the housing.

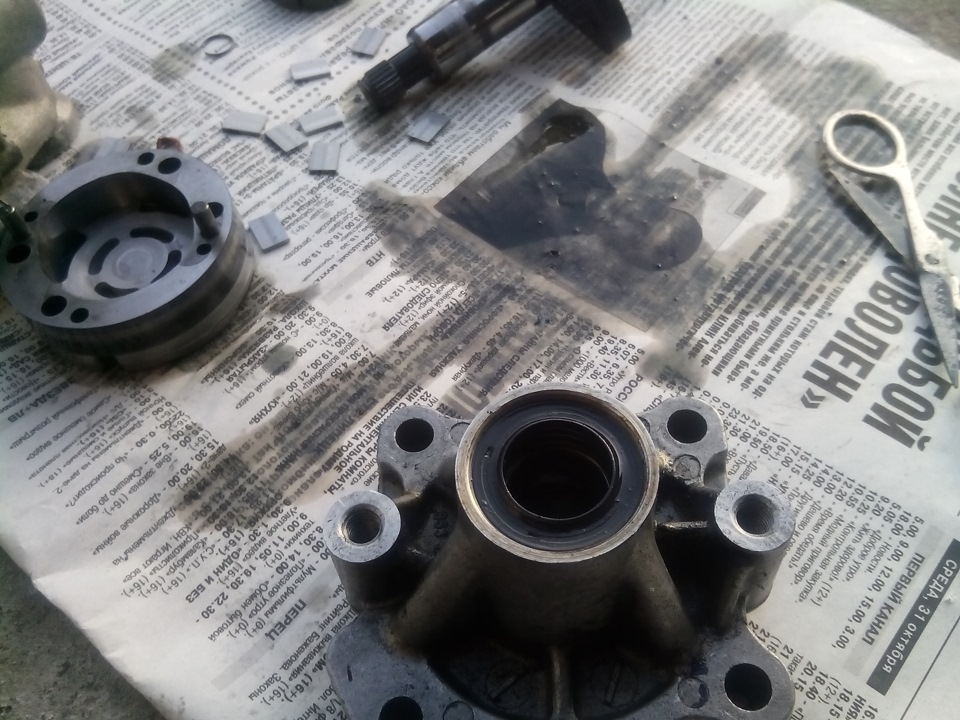

- Pull the blades and put on the pre-cooked numbered paper on the pre-prepared papers, so that during the assembly do not confuse anything.

- Attention! Remember the location of the blades in the assembled form. It is necessary that in the process of installation in the housing, the rounded zone of these blades was turned outward.

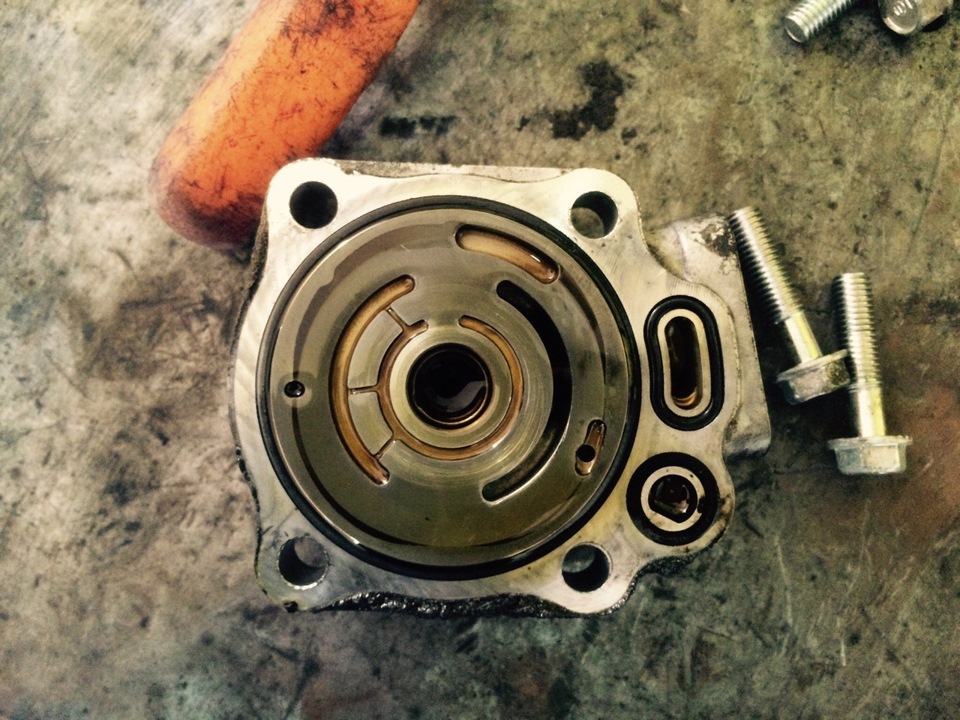

- Remove the plate and all the details that are under it.

- We knock out the shaft, carefully tapping a screwdriver.

- From the pump shaft, the bearing is pressed.

- We change the unsuitable bearing for pre-prepared.

- We check the details of the pump for wear and defects. Clean surfaces from roughness and dirt. According to experts, the simple cleaning of internal parts is able to reduce the gaps and shedding the work of this unit without replacing some components.

- The assembly is done in reverse sequence. Be sure to replace the gland, sealing rings, as well as washers to new, prepared in advance.

Tips Prof.

If it is difficult for you to independently fix the pump of the hydraulicel or you do not have time for it, replace the pump Gur to a new one, which will significantly reduce the repair time.

How to find and order a pump Gur and gaskets, auto parts at a table price and free shipping

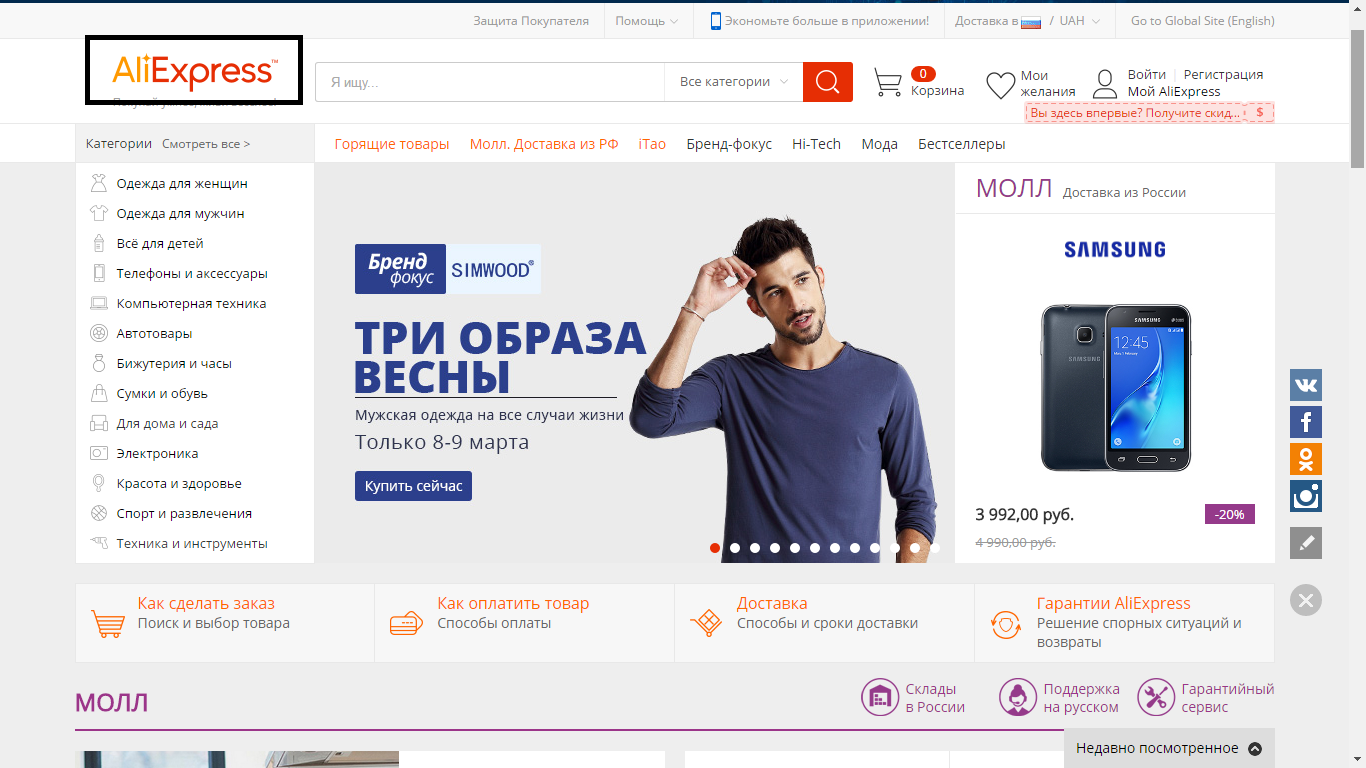

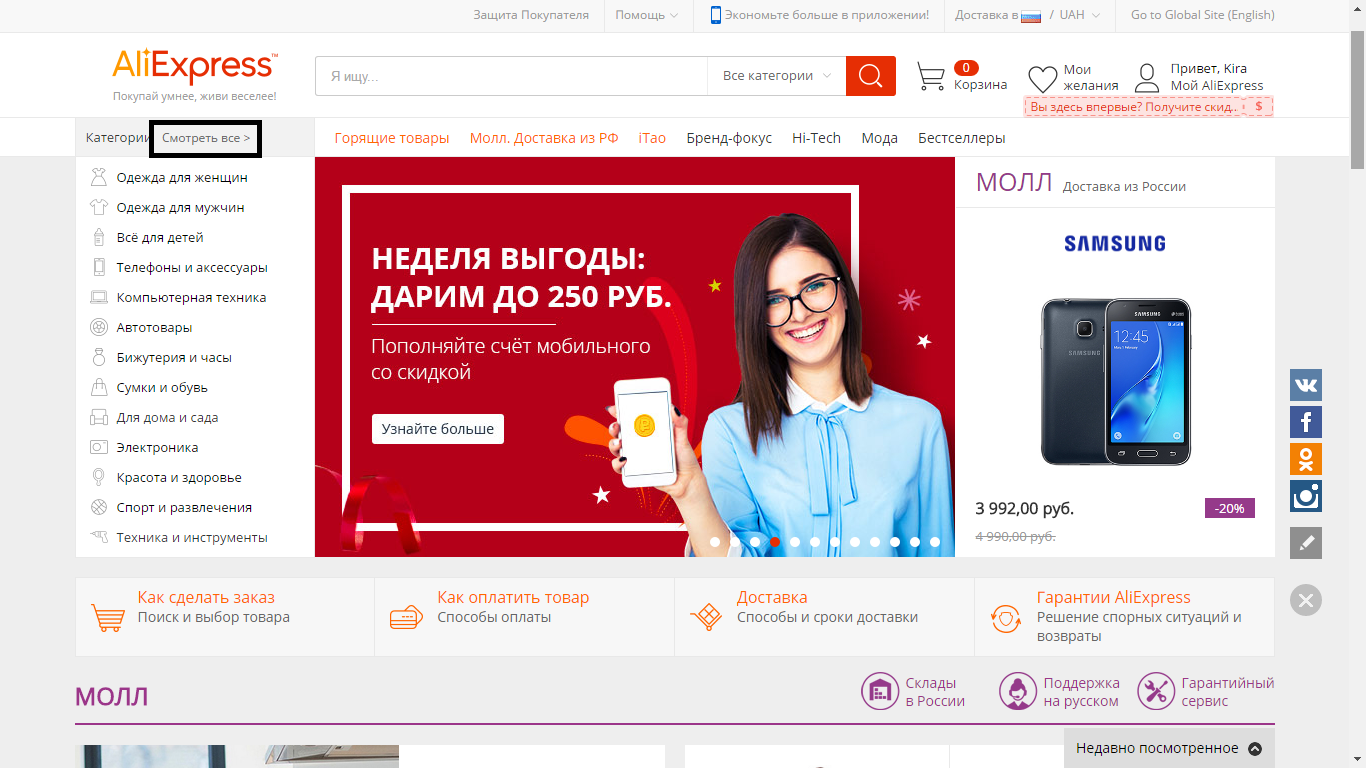

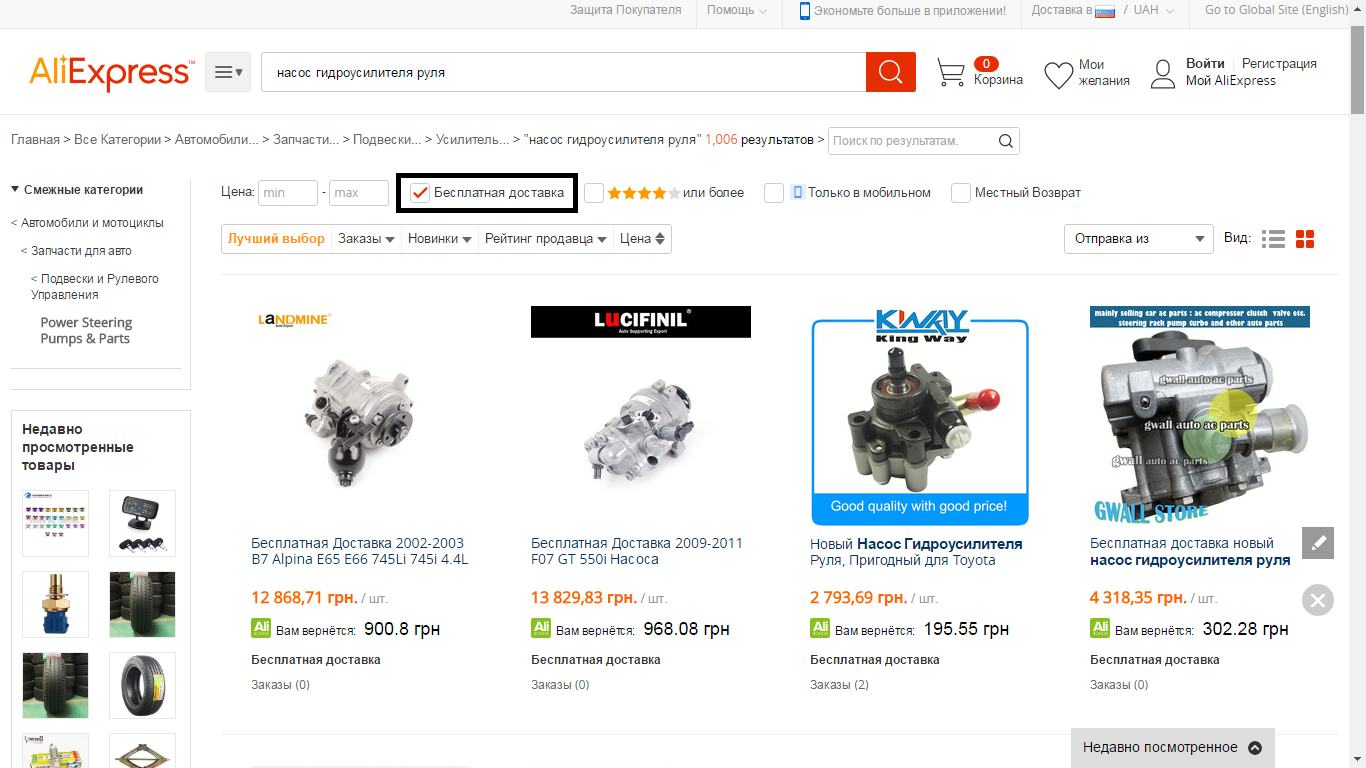

- Go to Aliexpress.

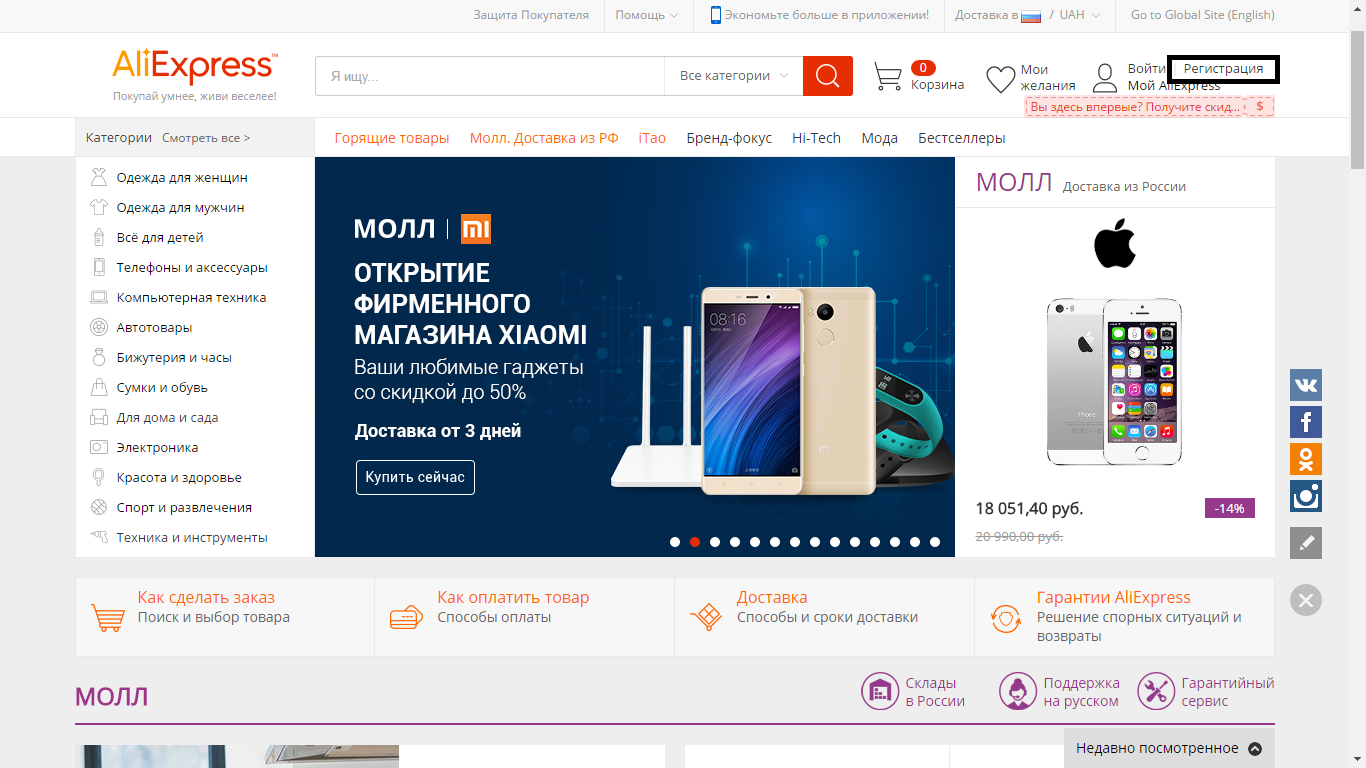

- Pass register. To register, click on the appropriate link in the upper right corner of the site. If you are already registered, log in to your profile using the password and login.

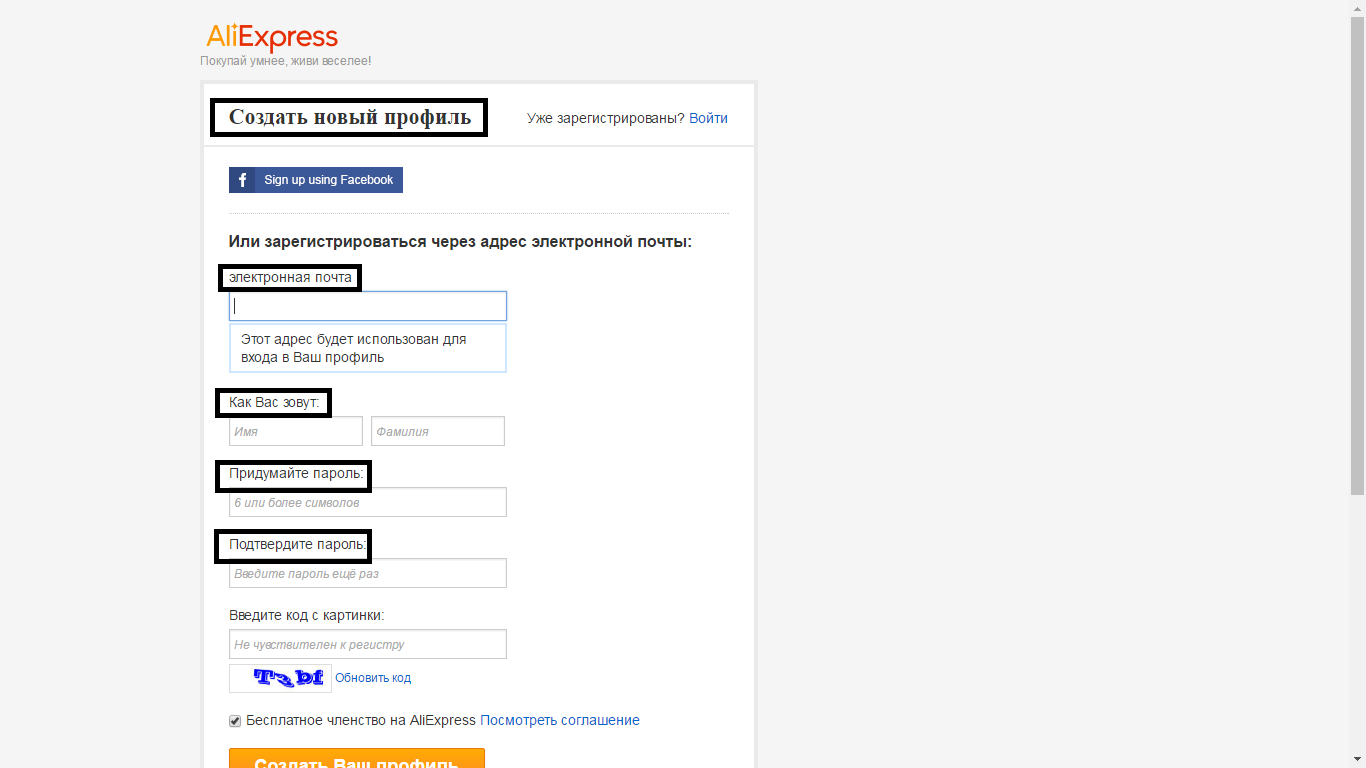

- Fill in a special registration form to which you want to enter: email, surname, name, and also come up with a password. It is very important to confirm the email address during the day, in order to avoid blocking your account.

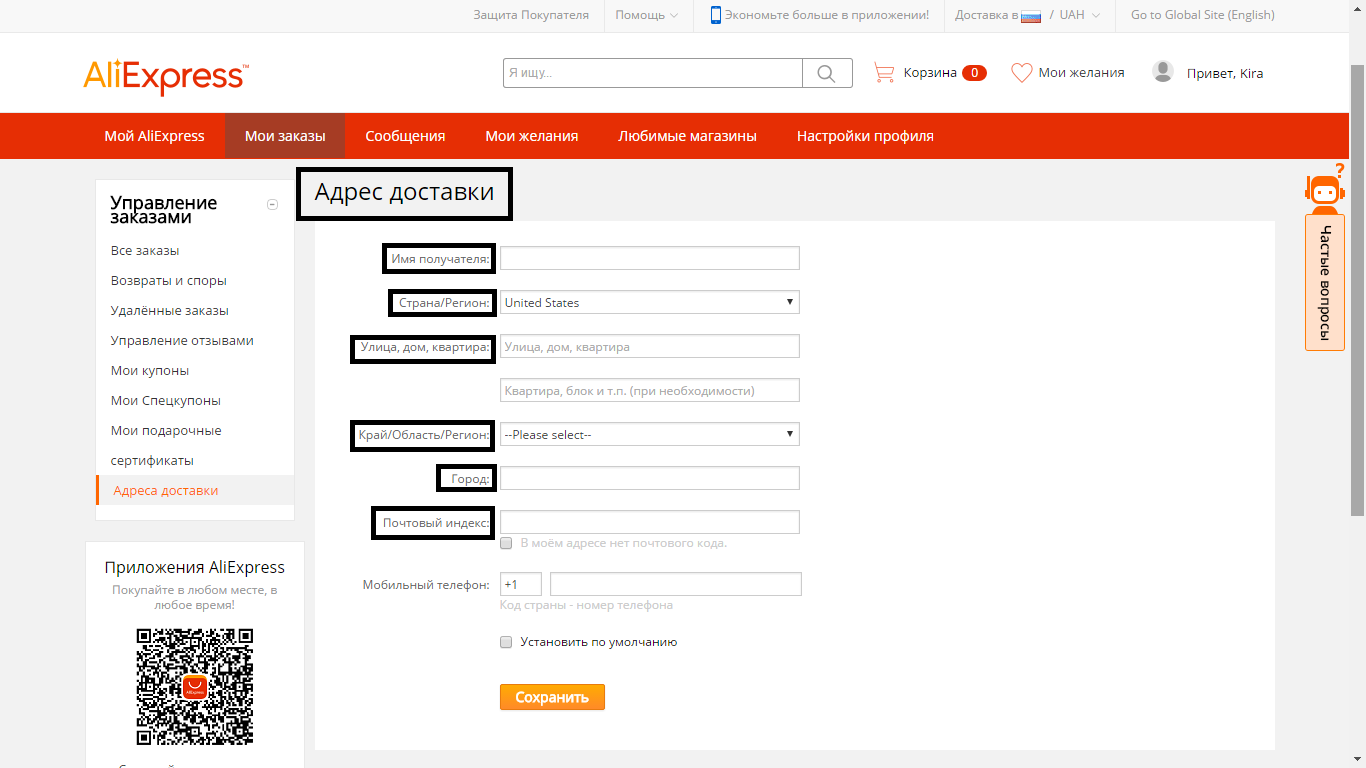

- Go to your profile, where it is desirable to immediately fill the shipping address so that you do not return to this when ordering goods. It is important to know that the shipping address is filled with Latin letters.

- Near the "Categories" row, click on the "Watch all" link.

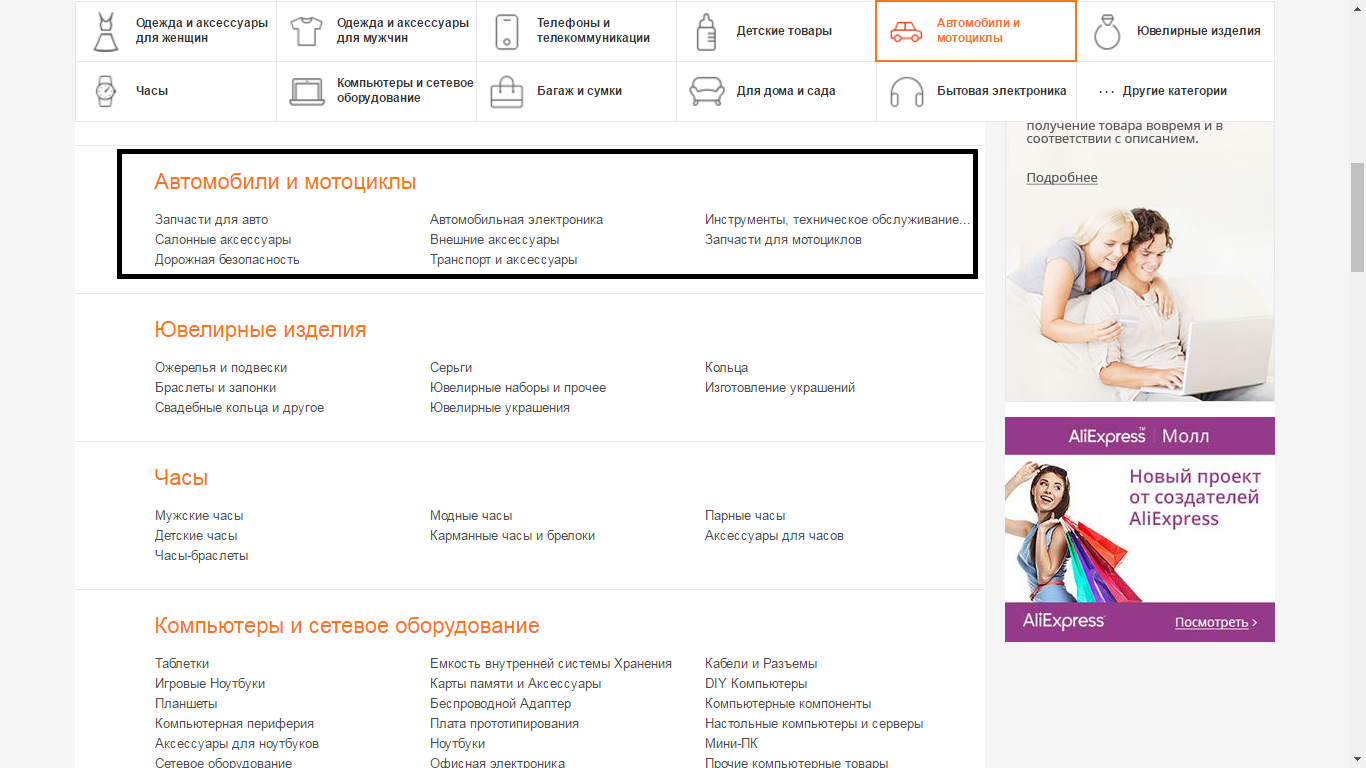

- Select the category "Cars and Motorcycles".

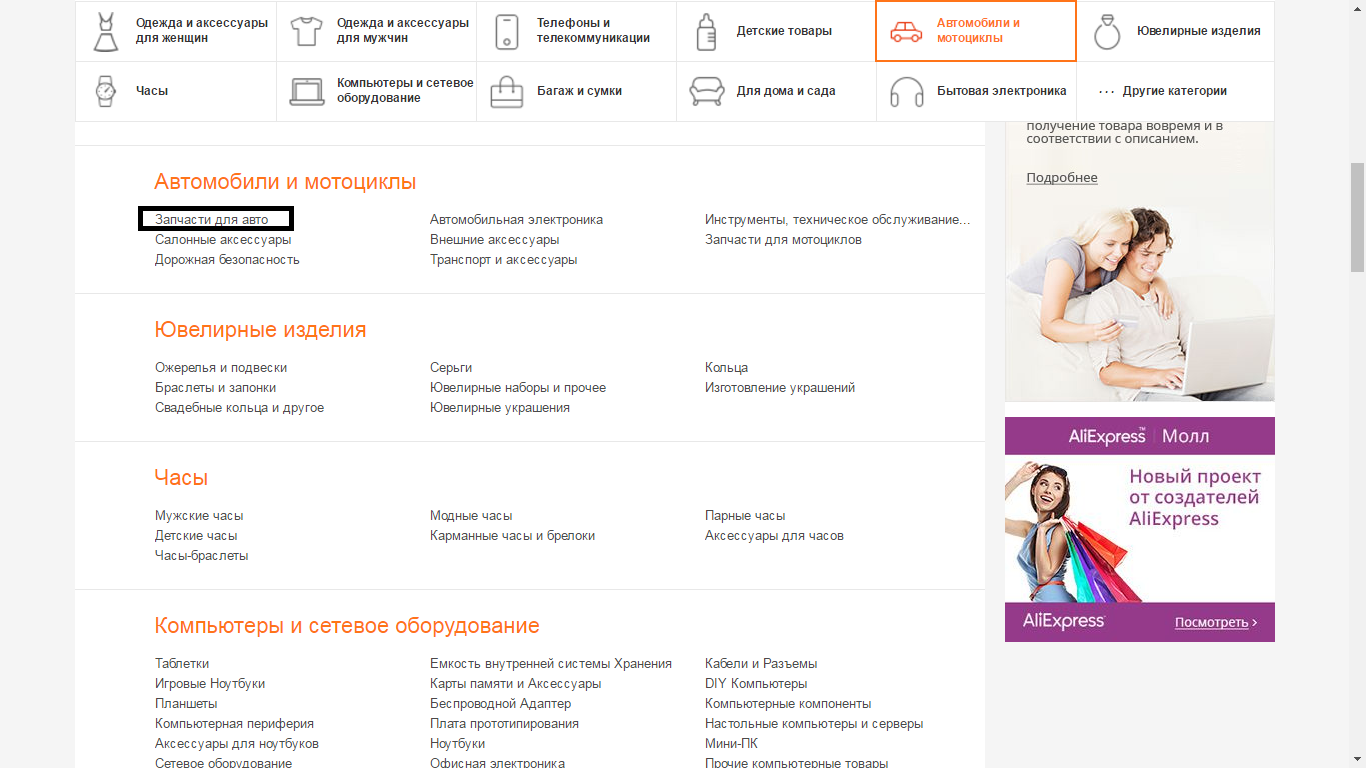

- Click on the "Auto Spare Parts" link.

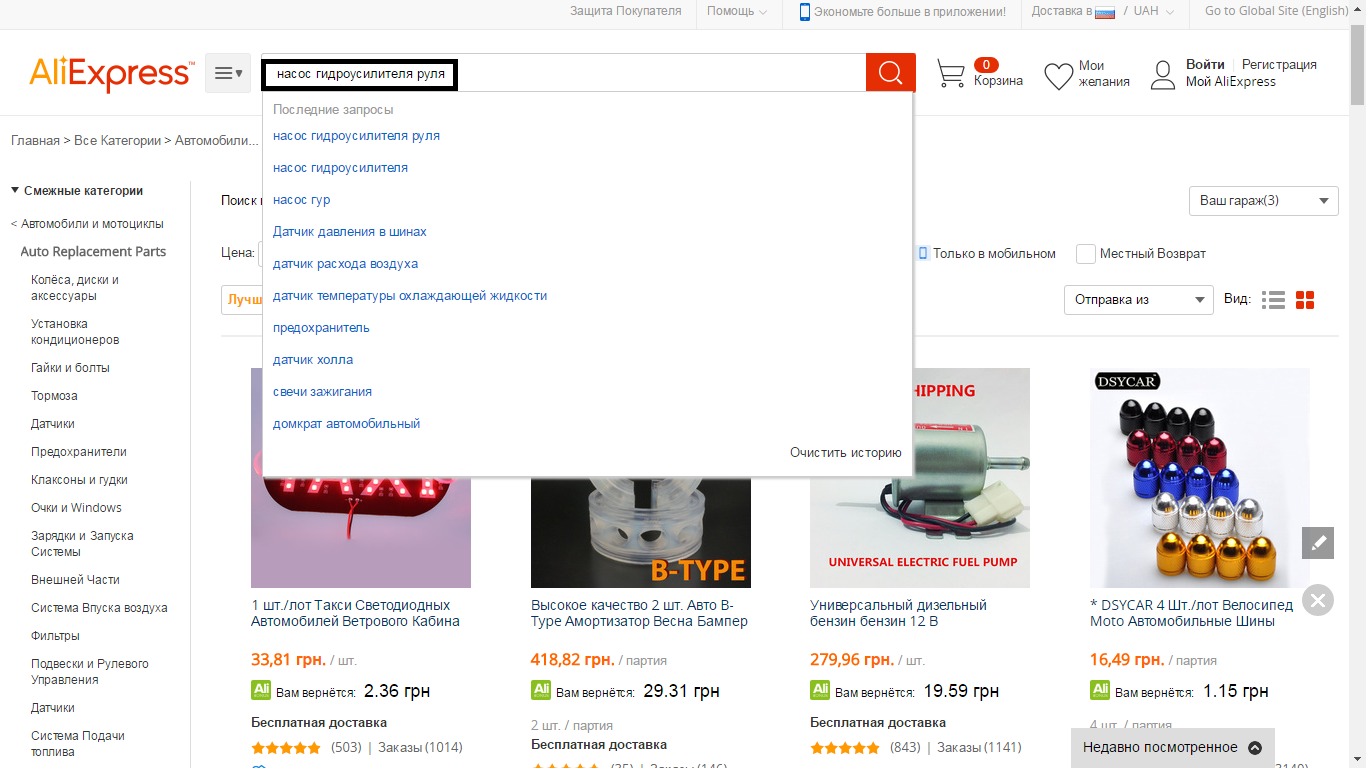

- In the search string, enter the name of the desired product, for example, the power steering pump.

- Choose goods with free shipping.

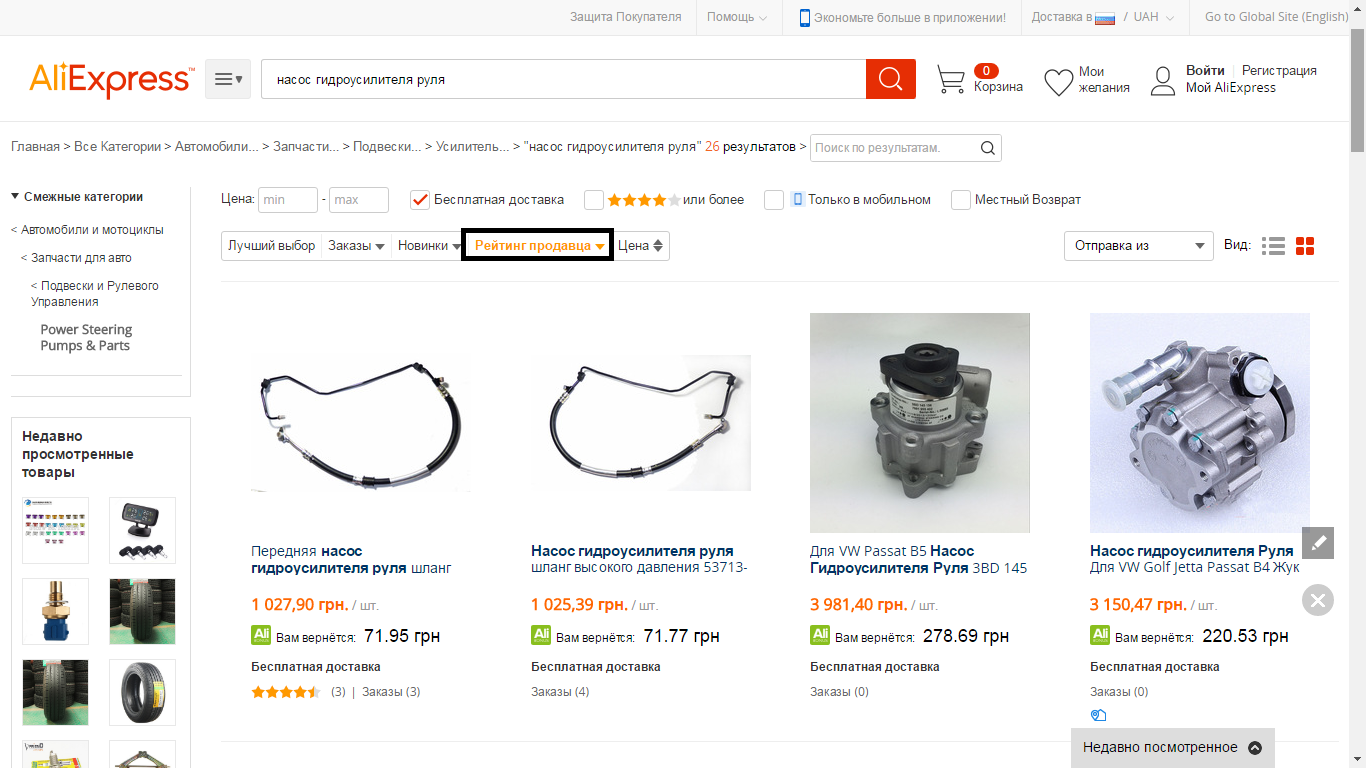

- Tear from sorting the seller rating.

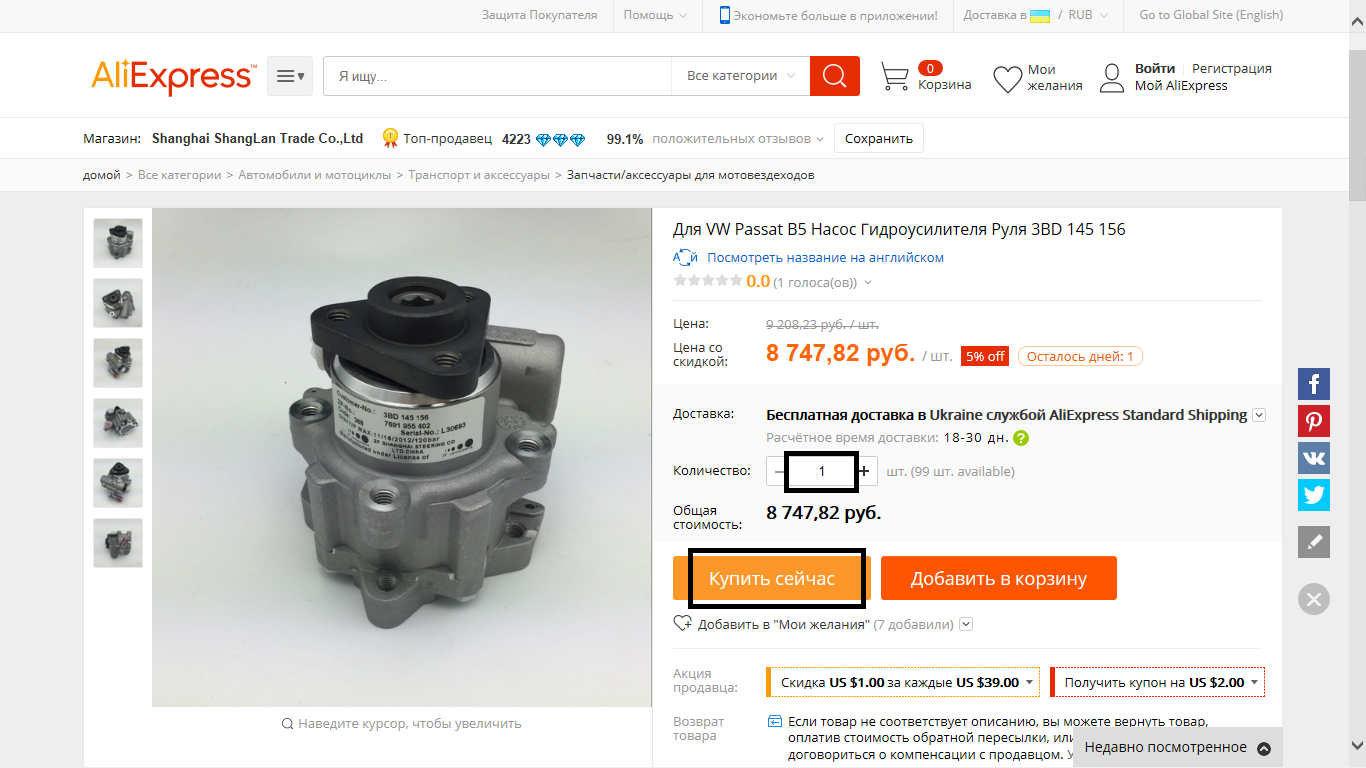

- Go to the product description page, where to select the required amount and click on the "Buy Now" icon.

- Pay for the order.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments