The comfort and quality of movement depends on the state of the rear and front suspension, as well as the safety of passengers and the driver. The key function of each suspension is mitigating driving and eliminating oscillations. But, in addition, the running part performs a number of important functions, namely: ensuring a smooth stroke, a decrease in rolls during turns, the provision of sufficiently high informativeness for the motorist on high-speed highway and in the city. To avoid problems associated with the suspension, it is necessary to systematically check it. But to determine the wear of silent blocks or suspension levers, it is absolutely not necessary to resort to the help of specialists - to check the condition of the suspension of the vehicle and on its own. About this further in the article.

Content

- Tools, Fixtures, Diagnostic Consumables

- VAZ suspension, from which the suspension consists, from which the life of the suspension elements depends

- Shrusa boot, bushings and silent blocks, how to determine in what state they are

- The boot of a VAZ scraper when it should be changed, in what cases are changing the rubber bushings and silent blocks

- Suspension cracks, in what cases can be used welding, and when it is only necessary to replace the part to the new

- Auto wheel crack, can you move on such wheels

- Shock absorbers and springs of VAZ suspension, how to find out in what state they are when you can repair, and when only replacement is needed

- VAZ suspension hinges, how to check the condition of the hinges of the VAZ suspension

- Bearings of VAZ suspension, how to check their condition.

- On which models VAZ are allowing the backlash of the bearing, and on what no and why

- What will happen if you turn the bearing when replacing

- Profi advice, if the details were replaced on the front suspension, why it is necessary to perform the collapse

Tools, Fixtures, Diagnostic Consumables

- Lomik.

- Calipers.

- Support.

- Standard tool kit.

VAZ suspension, from which the suspension consists, from which the life of the suspension elements depends

The service life of the pendant components is greatly different in different countries, and the quality of the road canvase.

If the suspension changes abroad rather rarely, then with our roads you have to change the suspension elements several times a year. Probably everyone saw a car that fell in the direction of the front wheel. This occurs as a result of late replacement of the lower ball support or front suspension levers. And well, if the speed was small at the same time.

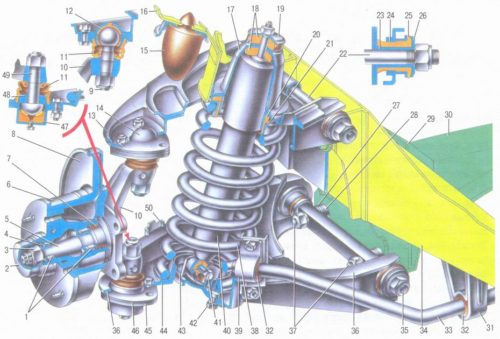

The front suspension of the car VAZ consists of:

Wheel hub bearings (1), hub cap (2), adjusting nut (3) washer (4), rotary fist pin (5), wheel hub (6), gland (7), brake disc (8), ball finger Supports (9), swivel fist (10), case for the protection of the ball finger (11), the bearing of the upper support (12), the upper suspension lever (13), the body of the upper support bearing (14), the compression buffer (15), bracket For compression buffer (16), the support glass of the shock absorber (17), cushions of the shock absorber (18), pillow pillows (19), insulating spring gasket (20), the supporting upper cup of the spring (21), the top lever axis (22), Internal hinge sleeve (23), outer sleeve hinge (24), rubber hinge sleeve (25), support washer (26), adjusting washers (27), remote washer (28), bracket, with which the spar is attached to the crossbar ( 29), crossing the front suspension (30), fastening bracket bar stabilizer (31), stabilizer rod pillow (32), stabilizer rod (33), lo KUZNA RCZON (34), axis of the lower lever (35), lower suspension lever (36), fastening bolts of lower lever axis (37), suspension spring (38), fastening rod stabilizer (39), shock absorber (40), fastening bolt Stabilizer (41), Nut, with which the shock absorber bracket is attached to the suspension lever (42), the bracket by which the shock absorber is attached to the lower lever (43), the supporting lower cup of the spring (44), the bottom support liner (45), Bearing Bearing Bearing Bearing (46), Ball Figure Coupler (47), Lower Support Bearing (48), Ball Finger (49), Wheel Turn Limiter (50).

Shrusa boot, bushings and silent blocks, how to determine in what state they are

Covers (not rarely called anthers) are intended to protect the responsible vehicle components from premature wear (for example, shruses). When diagnosing the chassis, the car must carefully examine the lateral of the hinges covers. Rubber sleeves in the components of the suspension are quenched by strong road blows, not allowing them to get to the body, and, at the same time, they act as hinges, providing mobility of suspension elements.

To diagnose the condition of covers, you need to feel their hands. If the finger shifted to the edge of the center of the faces, then the rubber bushing is broken or very worn. To determine the wear of the silent blocks (rubberometallic joints) of the suspension levers, it is necessary to act with a passage or by assembly to displace the lever relative to the body. The presence of a backlash or knock will indicate the wear of silent blocks. Look, there is no cracks on the protruding edges of the suspension levers, rubber sleeves and face shock absorbers.

The boot of a VAZ scraper when it should be changed, in what cases are changing the rubber bushings and silent blocks

Torn anthers entail a lot of other troubles, since dust and dirt accumulates in them, which in time falls into the node itself. When replacing the node, it is necessary to immediately change the boot - if you do not replace the torn boot immediately, the node quickly fails. If there are cracks on the covers that are speaking the edges of the faces of shock absorbers, suspension levers or rubber sleeves, it is necessary to replace them. If the rubber sleeve broke or worn out, it should also be replaced with a new one. As for silent blocks, they must be changed with their wear (in the presence of a knock or a backlash).

Sometimes the rear suspension rods have a tubercle, protruding the inside of the eye, which is able to quickly wipe the new rubber sleeves. This tubercle needs to run or replace the bar.

Suspension cracks, in what cases can be used welding, and when it is only necessary to replace the part to the new

All nodes and parts that are strongly loaded with vibrations and blows suffer from fatigue and cracks appear on them. For example, the levers of the front suspension VAZ are more likely to be cracked near the silent blocks, under the supports of the springs, as well as near the ball supports. If the cracking of the transverse thrust takes place as a result of the cracks (in the middle, where it is closed by protection, or at the edges, near the fastener bolts of the lower lever axis), then it should be replaced with a new one - to welding in this case it is prohibited.

As for the front suspension, in this case, it is possible to brew cracks in this case, but it is advisable to "back up" the place of repair, imposing patches. In addition, you can take advantage of welding if the bracket of the transverse rod broke on the VAZ.

Auto wheel crack, can you move on such wheels

Wheels of the vehicle cracked either do not bypass the party. Plastic Steel Wheels Over time, it is easy to crack near the ventilation windows or bolt holes. Ride on a cracked wheel is already dangerous. Even more attention is required fragile wheels with light alloy. After any impact, they must be carefully examined.

Shock absorbers and springs of VAZ suspension, how to find out in what state they are when you can repair, and when only replacement is needed

The behavior of the car changes greatly if the state of the springs and shock absorbers of the suspension is not important. When the vehicle comes out from the conveyor, the characteristics of all components of the suspension are carefully chosen - the shock absorbers are quite effective, and the springs are elastic. In reality, the springs are capable of breaking and lose elasticity, and when their condition is very running, they break and crack. As for the shock absorbers, then as a result of the loss of fluid, they cease to extinguish oscillations.

It is impossible to repair the requested springs, so they are changed to new ones. If the shock absorbers are collapsible, they can still be repaired, otherwise - also replacement. You can check the shock absorbers by alternately rolling of all vehicle angles. If the elements of the shock absorbers are good - they will not allow more than one and a half free swing, the defective will remind the swing.

VAZ suspension hinges, how to check the condition of the hinges of the VAZ suspension

The backlash is not only the source of the knocks, but also the key to the further accelerated wear of the suspension elements, so you should not bring everything to the deplorable state. Checking the status of steering hinges is made with an assistant - one of them shake the steering wheel, the second - proves each connection.

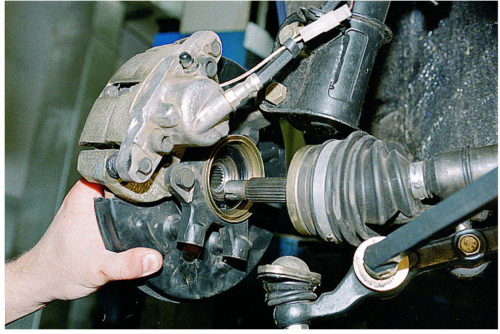

Swivel fist hinges on VAZ are checked differently. One presses the brake pedal, the second - shakes the wheel in the vertical plane. If there are stuffs, get ready for replacement. It will not be possible to check the state of the lower hinge if it is loaded with a spring force. It must be unloaded by submitting a support for the lower lever of the suspension. Next, shaking the wheel, look, is there no backlash in the bottom hinge.

To check the hinge on the actual wear, turn away from the bottom of the hinge threaded plug, after which it is necessary to measure the distance from the spherical head of the finger to the bottom side of the don. Norm - no more than 11.8 millimeters.

On transport with the Mac-Fersson suspension (for example, on VAZ 2110) to check the state of the swivel fist, it is necessary to squeeze the wheel. When the hinge is unloaded, with the help of a lomik, pressed the lever from the hub. If tapping, it means it's time to change.

Bearings of VAZ suspension, how to check their condition.

To check the status of the bearings, it is necessary to hang the wheel and not strongly swing it. If there is a backlash in the bearings, it will immediately be noticeable.

On which models VAZ are allowing the backlash of the bearing, and on what no and why

On front-wheel drive machines with double-row ball bearings should not be a backlash. A small backlash is allowed on the VAZ with roller conical bearings, especially on the old car. If you remove it using tightening the adjusting nut it does not work, then the bearing is strongly worn out and it should be replaced.

What will happen if you turn the bearing when replacing

When replacing bearings, you should not delay them too much. If you are dragging, the hub on the move will be very hot.

Profi advice, if the details were replaced on the front suspension, why it is necessary to perform the collapse

After repair and replacing the suspension items, it is mandatory to perform the collapse, which will improve the following indicators:

- Car handling.

- Car stability.

- Fuel economy.

- Reduced tire wear.

- Reducing car drifts.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments