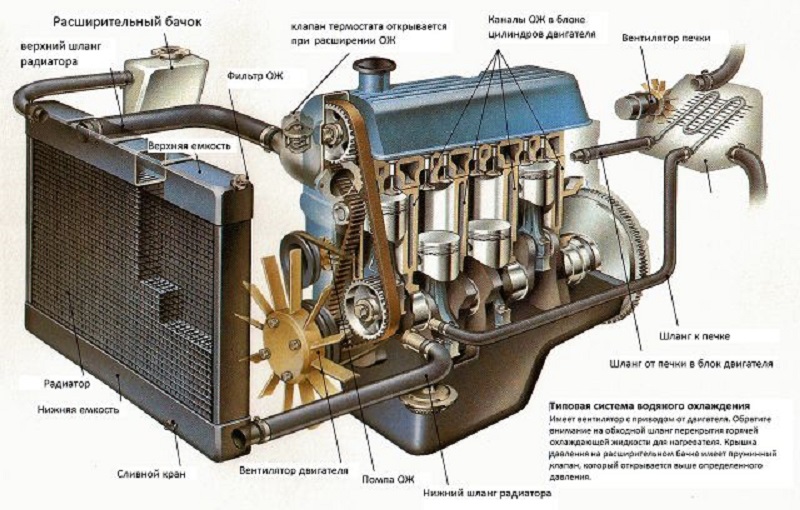

Like any engine, the car motor during work is heated, so it is necessary to constantly cool it. To do this, a cooling system is provided in the car's design. According to the principle of operation, they are two types: air and liquid. Liquid gained the greatest distribution, although they are more complex constructively. Air systems with their simplicity are much more prone to overheating.

Since all the motors are currently functioning with liquid cooling, a small plastic container with a lid is located in the motor compartment of any car, which is designed to fill antifreeze. It is called an expansion tank. In different engines, the expansion tank volume varies within 1.5-8 liters. About this further in the article.

Content

- Expansion tank of the car, where installed, why need

- How does a car expansion tank running

- Expansion car car: causes of a plastic expansion tank breakdown

- Ways to eliminate cracks of expansion plastic tanks

- Tools, fixtures, consumables

- Dismantling of the expansion tank of the car (step by step)

- How to pour a crack in a plastic tank (in detail)

- What sealant can be eliminated to flow in a plastic tank

- Tips Prof.

Expansion tank of the car, where installed, why need

Why do you need an expansion tank? The bottom line is that any fluids during heating are increased in volume. Thus, when water is heated to 100 degrees Celsius, its volume will increase by 4.5%, toosol and antifreeze - up to 6%. So that the coolant does not splash out when heated from the system, an expansion tank is required, which is a kind of compensator or buffer.

In the last century, there were no expansion tanks under the hood, since ordinary water was used as a coolant, and the top tank of the radiator was applied as a compensator, which was not taped under the string. When the cooling fluids based on ethylene glycol appeared, that is, antifreeze, which have a greater extension coefficient than the water, additional expansion tanks appeared so that the radiator does not have to increase.

Thus, the expansion tank (hereinafter referred to as RB) is designed to compensate for the volume extension of the coolant with an increase in its temperature. Located RB in the engine compartment so that the fluid level is approximately in the middle of the height of the tank. In this case, fluids in the tank and the radiator are at one level. Since the RB is above the radiator, the role of the filler neck is played by the RB cover.

How does a car expansion tank running

The expansion tank of the lid, polypropylene housing and two nozzles for connecting the hoses of the liquid system. With the help of the lower hose, the device is connected to the cooling line, and the top will take the pair and air bubbles from the system. At modern models, float sensors of the coolant levels are not rarely mounted.

For this option, the RB is equipped with another throat, which is designed to mount the sensor. On the side of the tank are control risks: from the bottom min and to the top MAX. In this interval, there must be a level of coolant.

To understand how the device works, consider the temperature modes of the functioning of modern engines. As you can see, the motors are functioning in critical temperatures.

| Motor temperature | Working temperature | Briefly | |

| 80-100 ° C. | 120-125 ° C. | ||

| Fluid boiling temperature (atmospheric pressure) | antifreeze | 120 ° C. | |

| tosola | 105-110 ° C. | ||

| water | 100 ° C. |

To raise the bar, the permissible temperature constructors increase the pressure in the coolant, due to which its booster temperature increases. For this, the system is sealed, and maintain overpressure in it. For different motors, this value varies in the range of 0.1-0.5 bar.

At the same time, a substantial vacuum in the free space of the expansion tank is unacceptable, since the air suits will occur in the system, which will lead to air traffic jams, which make it difficult to circulate the coolant and can lead to overheating. The pressure of the coolant supports a special regulator, which is in the filling lid.

In addition to protective function, the cover of the Republic of Belarus still performs the task of the pressure regulator. For this, two valves are collected in the lid: vacuum and safety. The latter is a rubber spring-loaded diaphragm, pressed outside and triggered when the pressure will exceed the spring force. Vacuum consists of rubber washers with a small spring, which is installed inside a large.

Expansion car car: causes of a plastic expansion tank breakdown

During operation, the car and its individual components acquire different defects. The Republic of Belarus is also susceptible to breakdowns, which lead to its depressurization with further leakage of the coolant as a result of such reasons:

- Strokes and other mechanical exposures.

- Long stay in boiling antifreeze tank.

- Plastic, from which the container is made, has an insufficient thickness, which leads to cracking of the walls.

- Increase pressure in the cooling system.

If you occur, you need to determine the location of the leakage and perform the repair of the expansion tank.

Ways to eliminate cracks of expansion plastic tanks

During the operation of the tank plastic undergoes multiple deformations: expansion and narrowing due to temperature differences. Functioning in conditions of limit pressure and temperature values \u200b\u200bentails cracking material.

Plastic, which is used in the manufacture of RB, is not able to join the reaction with glue of any brand, which is why it is impossible to perform high-quality gluing. The most widespread use of motorists have found such solvication of cracks:

- Plug the places of depressurization with special sealant, cold welding, epoxy resin.

- Seet the gaps in the RB housing using the reinforcement metal grid.

Epoxy resin and cold welding are used to close the gaps in the tank for a short time, for example, to get to a hundred or garage.

Tools, fixtures, consumables

To dismantle RB, materials and tools will be required:

- Capacity for fusion of coolant.

- Set of wrenches.

- Screwdriver.

Dismantling of the expansion tank of the car (step by step)

Order of work:

- First of all, loosen the fasteners that hold the plastic container.

- Drain Oh

- Disconnect the hoses and nozzles

- Remove the tank.

- Watch a problem space on the housing.

How to pour a crack in a plastic tank (in detail)

Order of work:

- With the help of a napkin, carefully clean the plastic in the fracture site from the residues of the toosol.

- Decrease the place of welding with acetone or solvent, dry.

- Cut the brass mesh strip, which consists of small cells, the length of damage.

- Take a mesh pay on the embedded junction.

- Evenly solder the grid to the edges of the joint so that the reinforced layer is formed throughout the grid area.

- We carry out the grinding of the seam.

- We apply a putty, primer and perform staining.

What sealant can be eliminated to flow in a plastic tank

For soldering, a soldering iron is used with a power of at least 40 W. In the absence of a metal mesh and soldering iron, the masters are used to repair the body of the tank, a special red polyathhese sealant for plastic DONEAL.

This agent has high heat resistance and resistance to the effects of oil liquids. Before applying a polyathizing in place of the defect, you need to perform thorough operations on stripping and degreasing, as well as removing traces of substances used earlier.

Tips Prof.

We recommend to see the following video:

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments