To date, the turbochargers are mounted in most vehicles, although earlier, this device has met only on dynamic machines having highly struken motors. However, this item is not particularly reliable, since it is necessary to repair it once every 100-250 thousand kilometers, depending on the care of the vehicle, its power and style of movement. It is worth saying that the turbine repair is internally impossible. The cause of the final breakdown of the node can be even the minimum shaft imbalance or the dirt inside the instrument. However, for each motorist, to replace the gaskets, rubber, bushings and other consumables on their own, without the help of service centers. In addition, each driver can wash the turbine independently, for which only ordinary car tools and repair kits are needed.

Content

Turbine - signs of malfunction

As practice shows, you should not disassemble the turbine if you are not sure of its malfunction. The consequences of such a rash action can be very sad. At a minimum, you will spend a lot of effort and time, and the breakdown will actually be completely in another part of the vehicle. And as a maximum, it can lead to a breakdown of a node, which will entail huge costs for the complete elimination of the problem.

The diagnosis of the turbine is a rather complicated process, but it is worth paying attention to some signs of her breakdown:

1. If the oil consumption is increased, and the lubricant drums are visible on the casing of the turbocharger.

2. If the engine sound has changed from the turbine, a cracking or a knock is heard.

3. If the motor significantly loses the power, which is particularly noticeable at elevated circulation.

4. If there is a strong smoke from the exhaust pipe, which acquires a dark nine or black shade.

5. If a fuel detonation occurs, cotton is heard in the exhaust manifold, and the vehicle moves by jerks.

There is no doubt that in accuracy to diagnose your car, assistance of professionals is needed. But the presence of at least one of the above symptoms is already a good reason to disassemble the turbine, at least to rinse it and improve the power parameters of the motor. However, you need to know how to repair the turbine, otherwise, its disassembly is meaningless and, in some cases, even dangerous.

Dismantling of the turbine to clarify the diagnosis

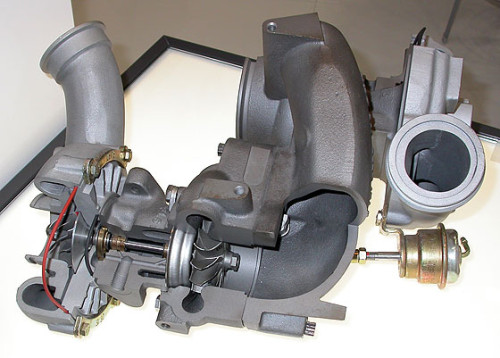

To diagnose this node, it is necessary to completely dismantle it. For this, you need to remove both elements of the mechanism - compressor and turbine, which are produced in the form of two separate snails. First, all nozzles and wires are required from the turbine, while it is impossible to touch factory connectors and fastenings, as they are difficult to restore. Now you need to unscrew the bolts to dismantle both elements of the node.

Often, the turbine compressor channel is removed quite easily, but the turbine channel bolts often stick to a metallic basis due to the effect of high temperatures. For their weakening, it is necessary to arm it with a conversion or a cash wrench. Then, apply not very strong blows along the instrument handle, thereby gradually freeing the turbine. If it is inactively removing the part, the turbine channel can be very shrinkable, on this it is recommended to produce five shots on the bolt and go to the next, of course, this process is long, but the necessary node will be saved.

As for the diesel engine, there are no exhaust gases in it, this bolts practically do not accumulate to the ground, which greatly facilitates the repair of the turbocharger. After removing both elements of the node, you must carefully examine the impeller. They cannot be repaired, on this, if you notice visible damage to them, you need to replace these components. Also, the play of the turbocharger shaft shaft should be measured, its transverse movement should not exceed one millimeter, and the longitudinal is generally unacceptable.

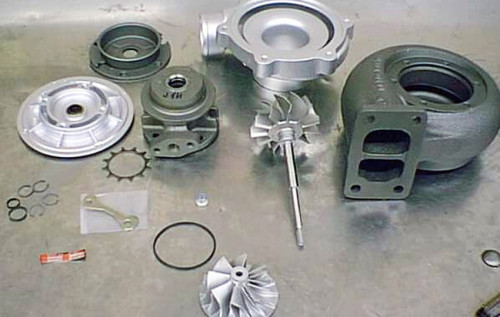

Turbine knot, work on the analysis of the turbine assembly to replace the consumables

If large elements of the turbocharger are not damaged, it is necessary to continue disassembling the node to find the source of the problem. First you need to remove the wheel of the compressor, in this you will help the puller, which is adapted to the left-sided thread. Also, you can help pliers and mandrels, which will hold the shaft. But, it is worth knowing that such tools are able to damage the turbine.

To make up this node to the end, you need to remove inserts from it and stubborn bearings, after unscrewing the bolts that hold them. You must be more attentive, since the elements from the turbine node are attached with two locking rings. When removing, it is important not to damage the clamps. After the execution of the actions described above, the car turbine will be completely dismantled and you can see the source of the problem. If you have not seen any faults, show the removed items by a specialist who will quickly and effectively establish the cause of the breakdown.

Is it worth producing a car turbine on their own

With independent execution of all works, itching the elements of the turbine before installing them back. As already mentioned, even the minimum sand can lead to a malfunction of the entire node. In addition, you should not forget that the broken turbine can fail the entire motor, which will significantly increase your expenses. Special attention should be given to such elements of the turbine:

1. Lands.

2. Oil intake tube.

3. Landing holes for shaft bushings.

To extend the life of the node, it is necessary to drain the remaining oil and thoroughly rinse the deposits, which remained in the hidden channels.

Next, you need to replace gum, bushings, gaskets and other similar products using Repair Kit. With a conventional syringe, lubricate inserts and bearings with engine oil. Also, it is recommended to rinse with a special liquid channels of the oil distribution system, which is not difficult to buy. If you are sure that there are no old oil, various dirt and sediments inside, you need to replace the worn items and collect everything in the reverse order. In addition, the oil and air filters should be replaced.

Regardless of which motor in your car - diesel or gasoline, you must carefully lubricate the node before starting. Pour about 25 milliliters of oil into the receiving neck and scroll through the shaft manually several times that the lubricant is evenly distributed. After the bulkhead of the turbocharger, it is impossible to allow strong heating of the engine or a long movement on high revs. Do not forget to change the oil in the car, so that there were no problems with re-pollution of the turbine.

In any case, it is not recommended to start repairing a turbine if you do not have the necessary tools or technical skills. Hanging the details of the turbine is very simple, but much more difficult to restore them. In the worst situation, you will have to replace the entire turbocharger, and it will cost approximately $ 800-5000 depending on the manufacturer of spare parts and the vehicle brand. Therefore, with any breakdown, it is better to repair a turbocharger in a special service center or a professional workshop, which has the necessary equipment.

By the way, the turbine installation significantly increases the power of the vehicle, as well as, gives a unique sound at elevated circulation. However, such devices are able to bring not only benefits, as well as disappointment with rather unpleasant consequences. Any mechanism is sooner or late to become unsuitable, and there are many reasons for this, ranging from the poor quality of the road surface and an inaccier ride and ending with the usual aging and wear of the parts.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments