The suspension is such a part of the vehicle, which is necessary to repair most often. This occurs as a result of the fact that the chassis is subject to considerable loads, and its elements - increased wear. One of the most basic hubs of the suspension, without which the vehicle is not able to exist, is a silent block.

Content

- Silent blocks what it is and how it is arranged

- Silent blocks for what they need

- SilentBlock is faulty, signs of malfunction

- Tools and devices for work

- Expendable Materials for Replacement Salentblocks

- Replacement of Silent Blocks of the Front Pendant, Step-by-step instructions

- Tips of professionals

Silent blocks what it is and how it is arranged

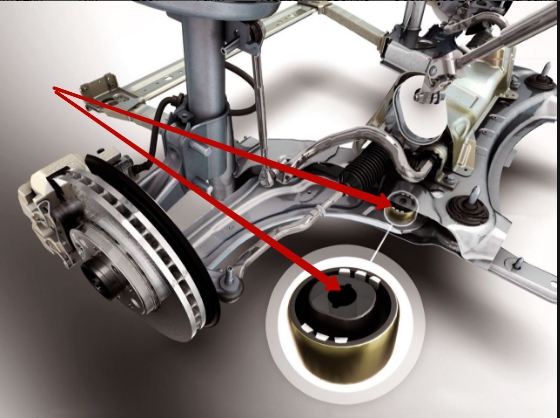

Silentblock (another name - a rubberometallic hinge) is called an element of a vehicle, the main task of which is to reduce the noise of the suspension.

Silentblock is represented as a hinge having metal sleeves on both sides, around which rubber inserts are located.

Silent blocks are produced from a variety of materials, but polyurethane is considered the most durable. At least these details are completely tiny, they are able to take on all blows and vibrations when driving, thereby protecting other elements of the movement of the vehicle.

Silent blocks for what they need

This part is an intermediary between the rigid body design and the pendant component (lever, shock absorber, reactive traction, transverse stability stabilizer, spring, subframe, and so on).

If you screw the metallic element of the suspension to the metal element of the body, the connection will be excessively tough, each pendant fluctuation will be heard, which will significantly reduce the level of vehicle's comfort.

SilentBlock is faulty, signs of malfunction

It is worn to understand that the silent block is worn out by deviations in the behavior of the vehicle. If the car has become more difficult in control, and the reaction to the rotation of the walnut steering column and with the delay, then most likely, these are signs of worn sielent block. To accurately determine what the problem is in the silent block, it is necessary to visit the nearest car service or independently inspect Rubberometallic hinges.

To visually inspect the silent block, you should call on the observation pit, clean it from dirt and carefully examine.

Signs of wear of rubberometallic hinges are breaking and cracks in the rubber part. When viewed, it is desirable to represent what a new rubberometallic hinge looks like.

An indirect symptom of silent block malfunction can be a collaboration curve, however, if it is known that he used to be correct. If silent blocks are torn, the levers are a little crooked.

In addition, check the backlash in silent blocks. If its value is more permissible, it is necessary to replace them urgently.

Another unpleasant sign of wear of rubberometallic hinges is the lateral uneven wear of the tires.

Tools and devices for work

- Torch and precipitant keys on 24, 19, 17.

- Chisel.

- Hammer.

- Vice.

- Special device for pressing silent blocks.

Expendable Materials for Replacement Salentblocks

Replacement of Silent Blocks of the Front Pendant, Step-by-step instructions

- First of all, the vehicle should be driven to the observation pit.

- Next, we remove the protection of the engine compartment if it is.

- Then unscrew the nuts fastening the front levers.

- After that, we unscrew the fastening nut of the front stabilizer to the lever.

- Now you choose a bolt with a turnup of a suitable diameter and let go of the wheel bolts, after which the robbery and remove the wheel.

- Then unscrew the nuts of the stretch marks, while cleaning the thread with a metal brush and smoem it with VD-40. Next, we take a ball support from the swivel fist, unscrewing two bolts. Now you can remove the lever.

- However, often unscrew this stretching nut is very difficult. In this case, you can remove the lever with the crab and stretching. To do this, it's enough from the crab to dissolve a little stretching nut and unscrew the bolts of the nut to the body. Now remove everything together and in a more convenient position we try to unscrew the stubborn nut. In extreme cases, it can be heated and cut out or unscrewed with a chisel.

- When the lever is removed, start changing the silent strokes. To do this, with the help of a chisel, we dismantle old rubberometallic hinges, we clean the eye from rust and take turns to press new silent blocks into the lever. Usually, the silent block does not fit completely, so the lever should be positioned on a solid and smooth surface, after which they annoy silent by a sledgehammer or hammer.

- Then change the silent block of the front lever. But, first you need to dismantle the old one. If the ripberometallic hinge is completely broken, it is enough to pull the metal sleeve and with a screwdriver to withdraw from the eye of the rubber part of the Silent. Before installing, a new silent block should be lubricated with a gel for washing dishes, liquid soap or soapy water. After that, we will prescribe it. Do not rush to tighten the bolt, correct the edge of the silent block, if it is converted.

- It is worth noting that after installing the lever, the nuts on the silent blocks must be tightened only when the vehicle is installed on the wheels.

Tips of professionals

If silent blocks are very worn, the vehicle may throw from side to side. It is not necessary to ignore this problem, as silent blocks have failed to destroy the landing places of the hinges, therefore, it will have to replace the entire element as a whole, which is more expensive and time consuming.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

12 years did not change the transverse levers, but they are not knocking, although the sleeves are supposed and the collapse is not done if they are not changed if there is no knocking turn?

Hello! If the collapse is not done because of the sleeves, and it is needed, it means you need to change.