The clutch is the main mechanism of the car transmission, which allows us without stopping the power unit, smoothly start from the scene and change the intensity of the ride, switching transmission to the go. However, in conditions of intensive operation of the vehicle, different clutch malfunctions can occur, which we will look at in this article.

Content

- Clutch, device and principle of operation

- Coupling VAZ 2110, device features

- Clutch disc, how to choose it to pay attention to

- The best manufacturers of clutch discs for VAZ 2110, Top 10 best manufacturers

- Possible clutch malfunctions

- If under the clutch, reasons and how to fix

- Coupling drops, completely does not turn on, reasons and how to fix

- The clutch works by jerks, causes and how to eliminate

- When you turn off the clutch creates increased noise, causes and how to eliminate

- noise adhesion when turning on, reasons and how to eliminate

- The clutch is sharply turned off at long work, causes and how to eliminate

- tight grip, reasons and how to eliminate

- The clutch disappears, causes and how to eliminate

- How to replace clutch disc

- Tips Prof.

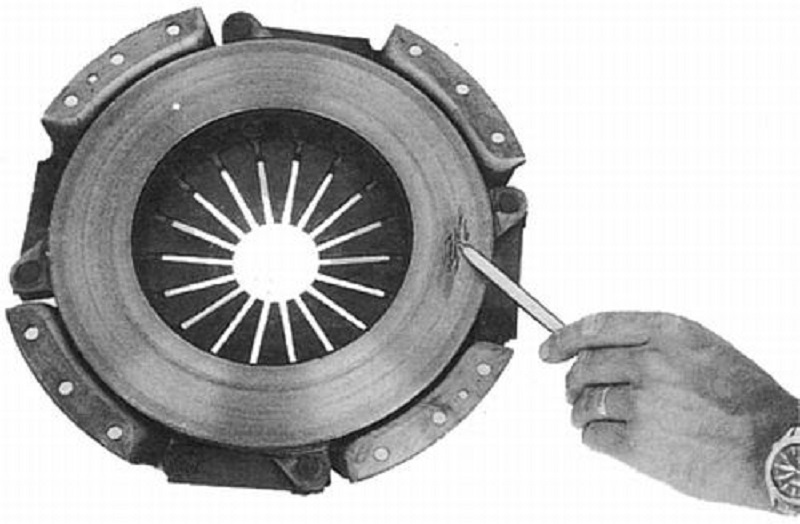

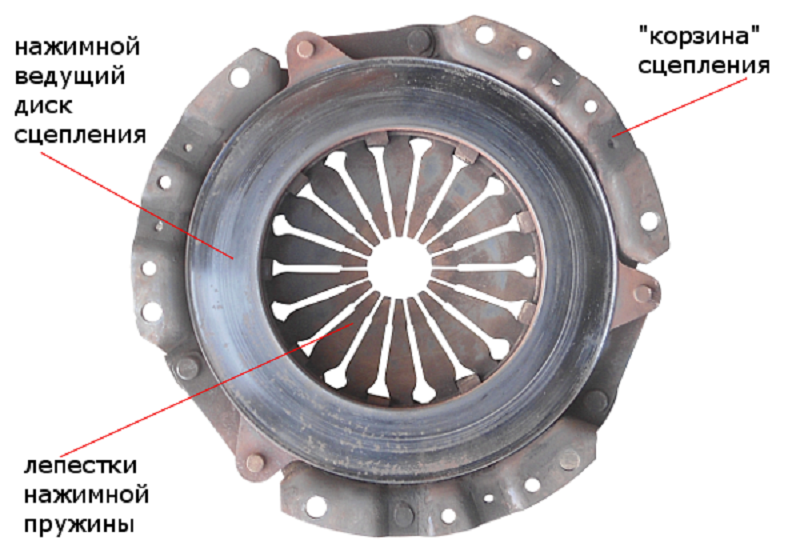

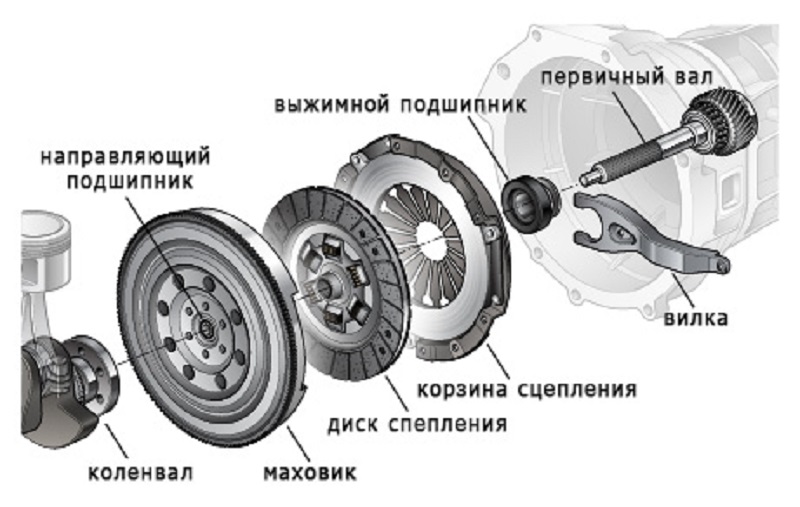

Clutch, device and principle of operation

The main elements of the clutch:

- Basket (clutch casing) - attached to the flywheel and combines all the elements of the clutch.

- Purpose disk - presses the slave disk to the flywheel.

- The slave disk smoothly connects the flywheel of the power unit with the drive shaft of the PPC.

In the included, working position, when the clutch pedal is discharged, the slave disk is sandwich between the flywheel and the pressure disk. The torque is transmitted to the presenter by exposure to the slave disk of the friction force.

When the driver presses the clutch pedal, the drive cable moves in the clutch casing and the lever turns relative to the fastening site. At this time, the free end of the plug has an impact on the release bearing, and it, in turn, moving to the flywheel, has an effect on the plates that move the pressure disk. At this time, the slave disk is exempt from efforts, pressing it to flywheel, and the clutch is disconnected.

The driver performs the transmission switching, and the release of the clutch pedal, again includes the adhesion of the flywheel with the slave disk. The grip is included.

Coupling VAZ 2110, device features

The specific features of the structure of this unit include:

- The characteristic structure of the springs of the diaphragm, which guarantees lowering the effort to turn off the clutch. This creates optimal conditions for driving a car on high and medium-sized circulation, and also affects the conversion of efforts to clutch pedals in the full / incomplete start area. This constructive feature allows an inexplicable driver to gently start riding, reducing the level of fatigue in travel conditions in the city, where you have to turn on the clutch.

- The rational choice of the amount of petals, the form of the spring springs, the correct structure of the spring supports, which is subject to mandatory control.

- The nonlinear properties of the spring are accurately calculated, given the preservation of the parts of the car: if the clutch begins to slip, then this happens shortly to the maximum allowable wear of the friction linings. So the clutch disc and the flywheel are protected from damage to the rivets of the lining.

- The mechanized finish of the blanks of the blank discs of the cast iron produced to optimize friction and wear-resistant properties. They are processed on high-precision turning semi-automatic matters, followed by the quality control of the working surface.

- Due to the special design of the shock absorption plate and the use of springs of different rigidity, the repayment of rotational changes occurs in several steps, which makes it possible to reduce the level of jerks and enhance the softness when the clutch is turned on.

- To create friction linings, raw materials with carbon threads and a reinforced additive, which increases resistance to constant friction, wear and centrifugal loads.

- The elements of the clutch housing are subjected to phosphate spraying in order to increase corrosion resistance.

- The execution of control dynamic and static balancing of clutch disks led to the formation of the final value of this node.

Clutch disc, how to choose it to pay attention to

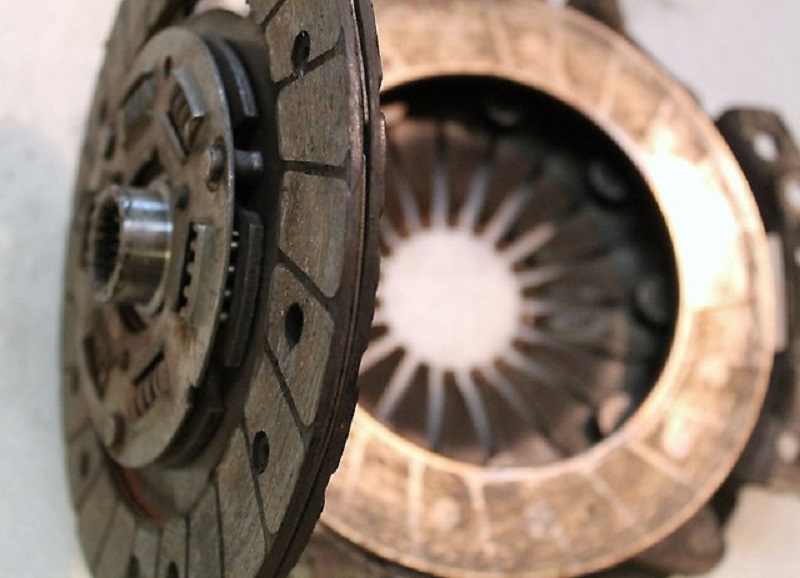

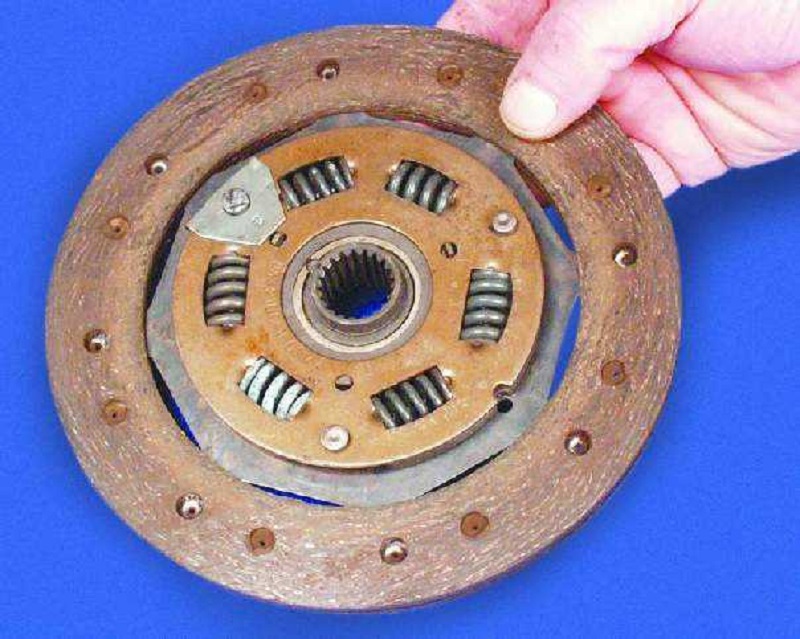

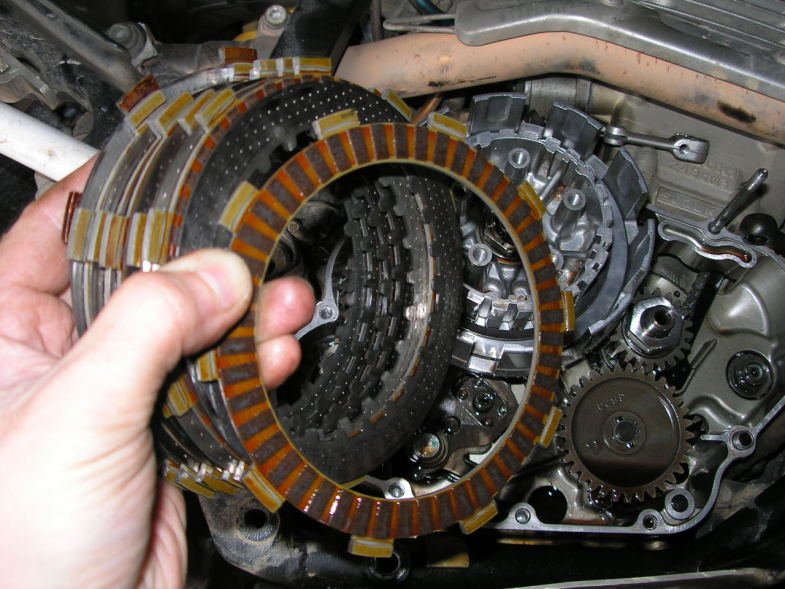

Slave clutch disc:

- The surface of the friction linings should be homogeneous, without cracks, rough roughness, jackets and chips. Landing of the lining or the presence of spots of other liquids is not categorically allowed. These requirements Many manufacturers of cheap or "left" disks are not able to do, since a high-quality pad is the most expensive item.

- We inspect the quality of the riveting both rivets of the damper plates and small rivets of the disk (slave) with friction linings. It is necessary that the smelting of each rivet was strictly identical to otherwise and had a uniform film at the edges. It is categorically not allowed by the backlash or displacements of friction linings and damper plates relative to each other. As for the springs in the damper, they also should not be peeled. These indicators talk about good equipment, which was built with a slave disk, which manufacturers of cheap or "left" disks cannot afford.

- On the working slots in the hub should not be loops and damage. The presence of traces of oil is allowed.

- Look at the label on the damper plate. Most manufacturers prefer to apply their trademark exactly here. It may be laser marking, hologram, stigma or fire signs. And although this method of labeling is used not all manufacturers, still you should pay attention to it.

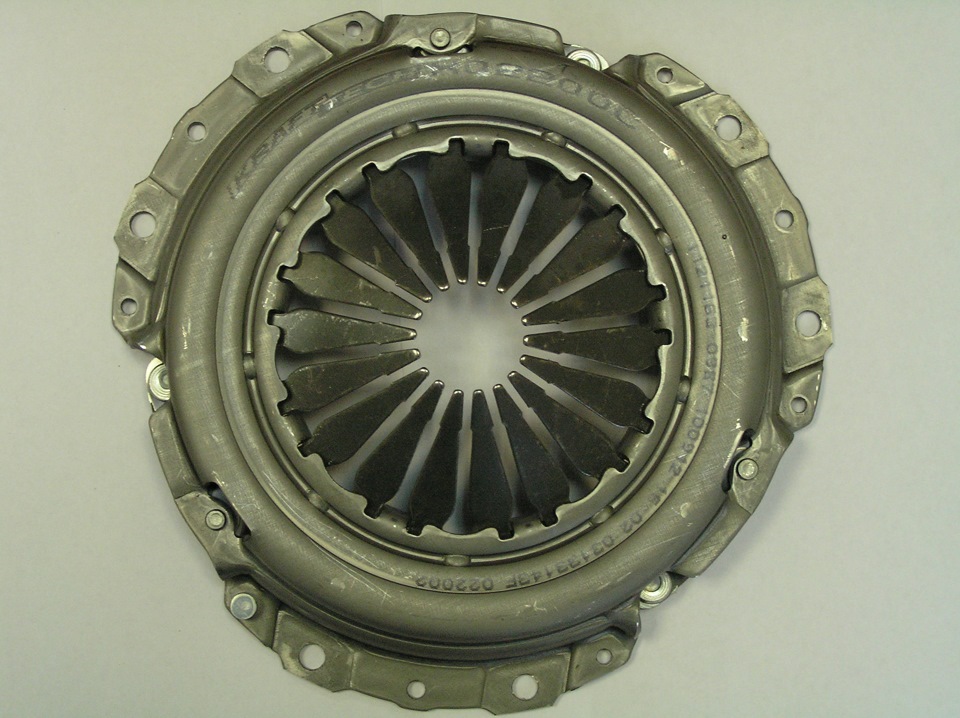

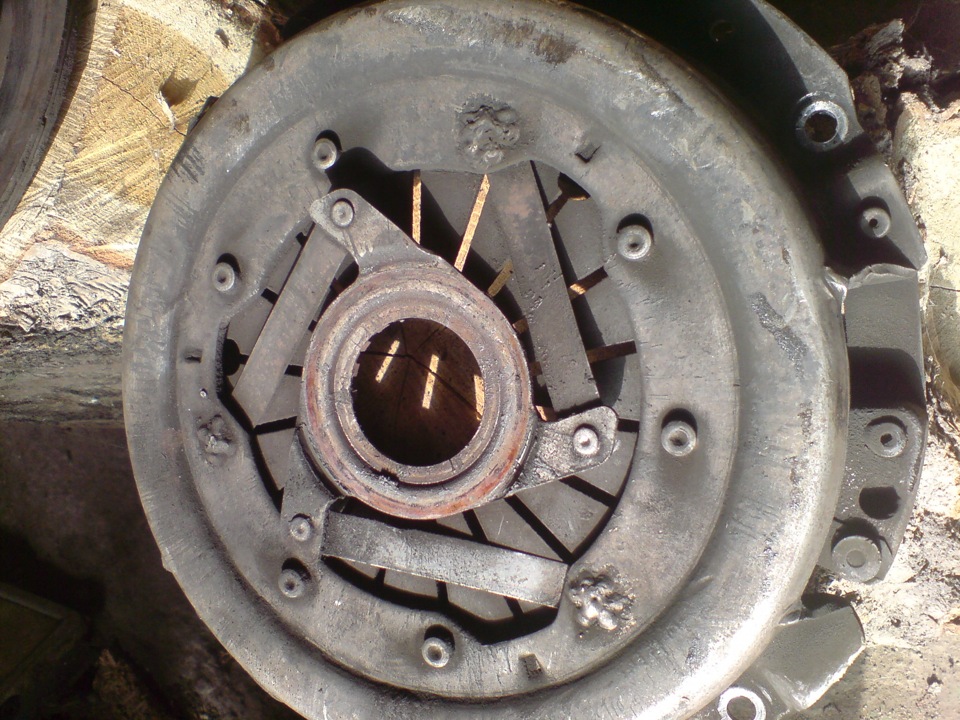

Clutch pressure disc:

- It is necessary to check the quality of the plug-in plates, which are located around the perimeter of the basket. As already mentioned, rivets should have symmetric flangshell, look carefully and be identical to each other, which eliminates the garage assembly and speaks of serious production.

- Check the casket casing skirt. The housing of the pressure disk in serious production is usually manufactured by the method of stamping. Therefore, the presence of burrs on the skirt (flanging) of burrs, scratches, or scratches are not allowed. The presence of burrs in the holes is also not allowed.

- Special attention to cast a clutch disc, which is from the opposite side of the basket. The disk mirror must be high quality. If the quality of the mirror is high, it means the risk to buy a fake disk is very small. Consider so that there are not even the slightest irregularities, microcracks and shells. This indicator indicates about the compliance of the cast iron brand used when casting a disc, and the use of high-tech equipment during its processing.

The best manufacturers of clutch discs for VAZ 2110, Top 10 best manufacturers

- Vis - Russia.

- Sachs - Germany.

- LUK - Germany.

- Hola - Netherlands.

- Valeo - France.

- Starco - Turkey.

- Pilenga - Italy.

- QML - Germany.

- FINWHALE - Germany.

- MAPA - Turkey.

Possible clutch malfunctions

- The adhesion of the vehicle does not turn on completely and ranks. As a result, switch transmission or is very difficult, or impossible at all, especially the rear and first.

- During a sharp press on the clutch pedal, the engine begins to gain momentum, but the car does not accelerate. This situation is especially dangerous when overtaking when the motorist, not knowing about the problems with the clutch, is trying to overtake the vehicle going ahead.

- When attaching, jerks are observed.

- The clutch does not turn off completely, and during the shift gear, a specific crunch is heard.

- When driving the car rattles, noise or knocks, and during the inclusion of clutch, the sounds are only enhanced.

if under the clutch, reasons and how to fix

The gear shift is always difficult, especially the reverse and first transmission. In addition, when turned on, specific noise is heard. In this case, the gearbox is fully proper.

The most common cause is incorrect clutch adjustment. In this case, it is necessary to replace the deformed fork and adjust the clutch drive.

Another reason - clutch Drive Cable Jealing. In this case, you should lubricate the clutch cable with a motor oil or other means. If it does not help, the cable will be very integrated, fulfill its replacement.

Boxing in the clutch or weakening Rivets FN.In this case, only the disk replacement will help.

The presence of jackets on the surface of the flywheel. In this case, it is necessary to replace the flywheel if the uneven and strong wear is observed. But if the pressure disk is damaged, you have to change the basket.

Slave disk hub.This is a fairly common phenomenon and in this case will help the following: Clean the slots from small damage and dirt (applied in the applied). With substantial wear, change the clutch disc. Sometimes the primary shaft of the gearbox changes, and not the disk itself.

Balance or skewed ND.On the surface of the pressure disk there may be elements of skewing and warping. In this case, you will have to change the clutch basket.

Wear springs petals.Again, in addition to replacing the basket, it will not help in this case.

coupling drops, completely does not turn on, reasons and how to fix

The clutch turns on not completely or sinks. The power unit begins to gain momentum, but the vehicle does not accelerate. This is particularly noticeably felt on the rise and when moving uphill. In this case, the driver can even feel the smell of friction linings. Also significantly increases fuel consumption. This can occur as a result of the following faults:

- Milling overlays, pressure disk or flywheel.

- Highly burned down or worn friction pads of the disk.

- The clutch drive is damaged.

Summise.In this case, take gasoline or white spirit and rinse thoroughly with this means of grinding surfaces. If the slave disk is grilled very much, it is desirable to replace it, because cleaning here will no longer help. In addition, it is necessary to eliminate the cause of grinding (lubricant leakage via engine glands or gearbox).

Floating or wear of FN (friction linings). If friction linings have signs of burning or wear out, replace the slave disk, as nothing else can help.

Clutch drive.If the clutch drive is hired or damaged, it is necessary to eliminate the cause of the jealous. If this is not possible, replace the drive.

the clutch works by jerks, causes and how to eliminate

There are several reasons due to which the clutch can work jerks.

Hences the drive cable.In this situation, lubricate the cable with a motor oil, and if it does not help, replace it.

Singing the VV hub on the slots.Clean the slots from small damage (using a file) and dirt. With substantial wear, it is necessary to replace the DV or primary shaft. Before assembling the hub, do not forget about applying lubrication slots. For this, the SCLM-4 is ideal.

Weakening overlays and deformation of the VD.To resolve the problem, replace the VD. The slave disk changes with a substantial precipitate of the springs of the exterior, the loss of elasticity of the plates, the wear of the windows of the spring and so on. If there is a grinding of FN or jackets on the flywheel, replace the basket.

when you turn off the clutch creates increased noise, causes and how to eliminate

If you hear strong noise when the clutch is turned on, it says about leakage of lubricant or bearing wear. In this case, it is necessary to replace the bearing.

noise adhesion when turning on, reasons and how to eliminate

The reason is a breakdown or a substantial precipitate of the springs of the exterior, wear of the windows of the spring. In this case, replace the VD. In addition, in this case, the reason may be due to the deformation of the slave disk by either weakening the fastening of friction linings, which is eliminated by replacing the VD.

the clutch is sharply turned off at long work, causes and how to eliminate

Sometimes, with a long work, the clutch can dramatically turn off as a result of the release of the release bearing on the guide sleeve of the PPC. Solve the problem can be replaced by worn items.

tight grip, reasons and how to eliminate

There are several reasons for such a breakdown. The most common of them is the jamming of the cable or lever, the bearing wear of the fork. The problem is solved by eliminating the cause of the hot and replace the worn bearing.

the clutch disappears, causes and how to eliminate

- A clutch cable broke. To solve the problem, it is necessary to replace the cable.

- Floored or burst the return spring. If the spring flies, return it to the place, if it burst - replace.

- Broke the plug on the clutch. It will have to be replaced.

- Air entering the hydraulic system. In this case, only grip clutch will help.

- The clutch pedal failed, but turn on the clutch briefly succeeds only with a sharp press on the pedal. In this case, the wines of everything is the main cylinder of the clutch - wear or defect of the Cuff Cuff, mirror defects. Solve the problem can be replaced by the main cylinder.

How to replace clutch disc

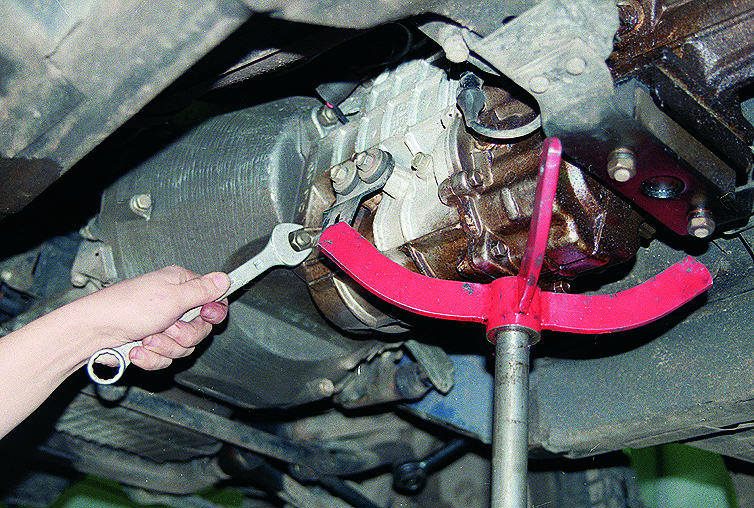

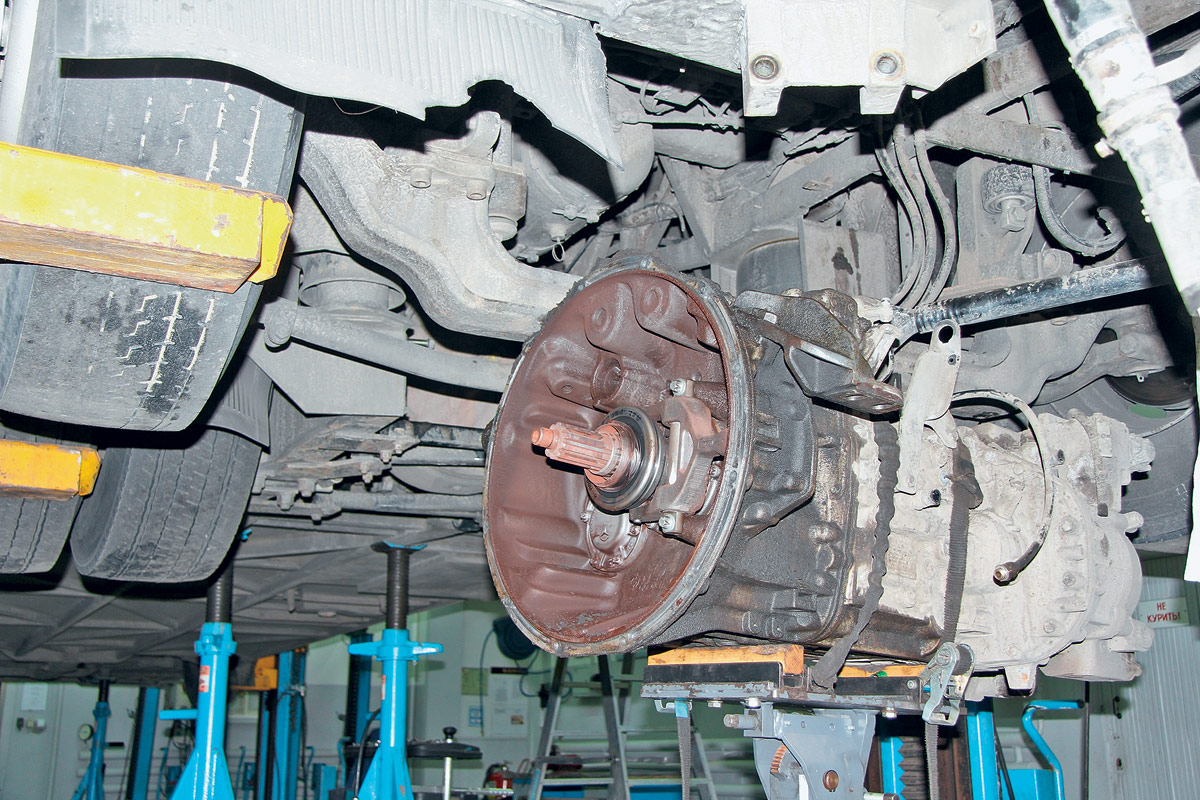

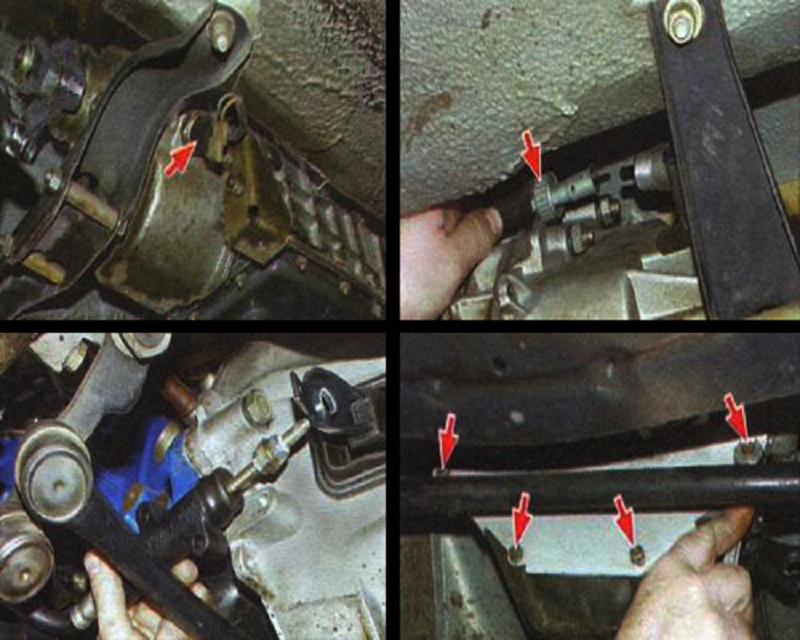

So, proceed to replacing the clutch disk. To reduce labor intensity, we will perform without dismantling the box.

preparatory work

- Talk the car on the overpack or the observation pit.

- Disconnect the negative battery terminal.

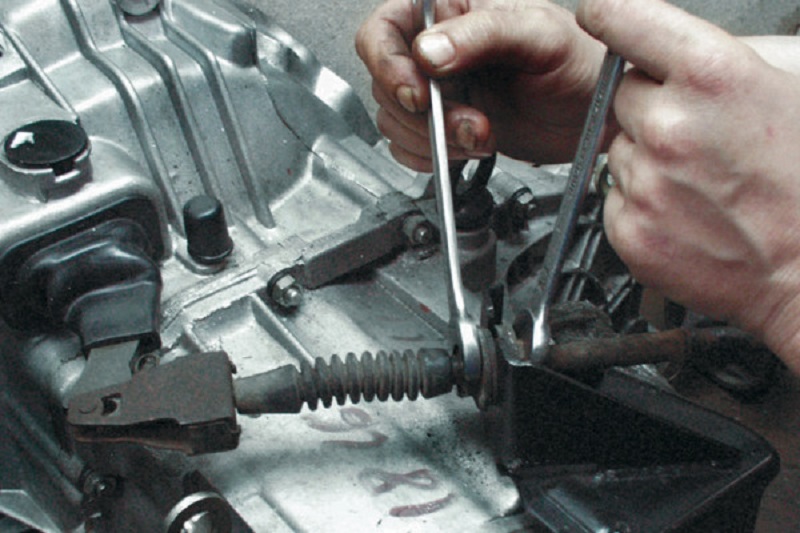

dismantling (step by step)

- Remove the clutch working cylinder.

- Take off the cardan from the gearbox.

- Remove the speedometer cable.

- Disconnect from the contact group on the PPC of the reverse lamp wire.

- Disconnect the clutch cliner from the cylinder block and cross the rear support of the power unit from the body.

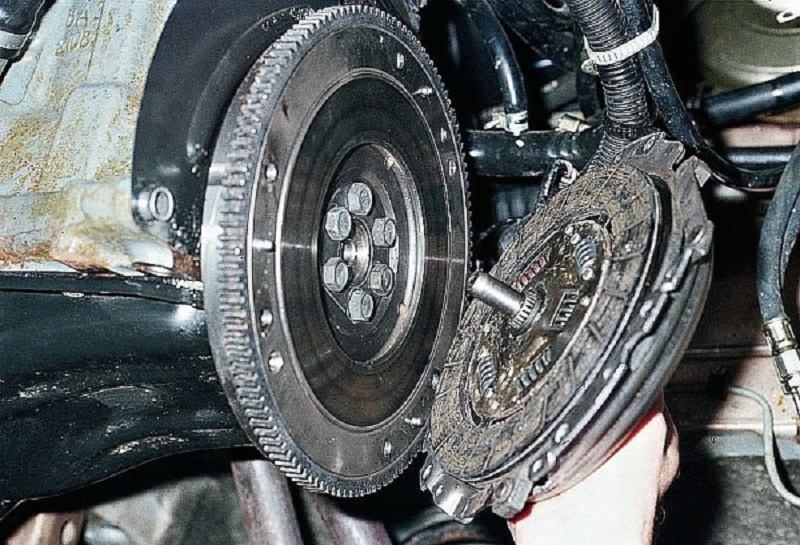

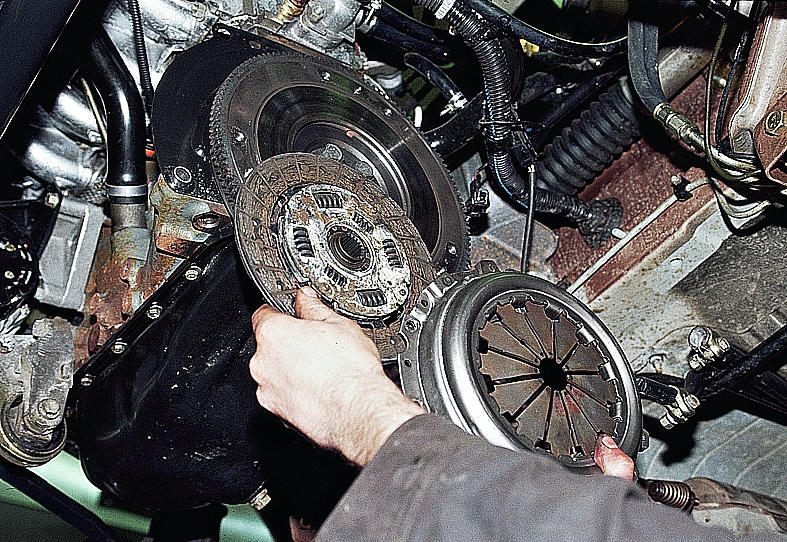

replacement of clutch (step by step)

- Remove the fastening nuts of the PPP support, slide it back so that the gear shift handle resigned into the back of the floor hole. Under the back of the box, substitute a reliable backup, and its front will be held in the silencer.

- Holding the flywheel by mounting, unscrew the fastening bolts of the clutch housing, turning the crankshaft to access them.

- Move the clutch basket and remove the slave drive spent. Instead, put a new one. Before mounting the flywheel and a new disc, wipe the rag moistened in gasoline.

clutch adjustment

The installed disk adjust relative to the center of the bearing in the end of the crankshaft. Do not forget to adjust the free stroke of the clutch pedal after the assembly. How to do it, you can learn from this article https://prosedan.ru/regulirovka-hoda-pedali-scepleniya-regulirovka-hoda-pedali-scepleniya-vaz-svoimi-rukami.

Tips Prof.

As you can see, replacing the clutch disk - a simple procedure, easily performed by a car enthusiast at home. More about replacing clutch disk on VAZ cars you can learn from the video.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments