Suspension is one of the vehicle's most important sites. Her condition is necessary to constantly monitor, because the failure of even the smallest element of the suspension can become a huge problem. That ball bearing is one of a small, but extremely necessary suspension components. As with all elements of the vehicle, sometimes it needs to be replaced. Sure, you can enlist the help of professionals and replace the ball joints in the workshop. However, this event is quite feasible in the conditions of the garage, for which the car owner will need a little time, patience and a special puller for ball joints.

Content

Ball bearings which are in the car

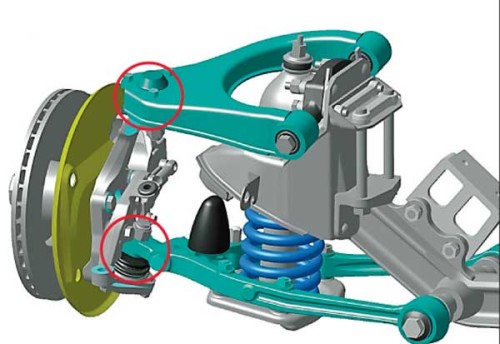

The ball bearing is called a very important element of the vehicle that is included in the design of the suspension. It connects the lower arm and the hub steered wheel.

The main objective is to provide a ball joint rotatably the hub wheel primary horizontal position during vertical displacement.

Initially, the ball bearings mounted only on front-wheel drive cars, so that the wheel turns around the vertical. However, since the inception of the ball joint much in its design changed.

The ball support is made in the form of a cone-shaped form with a spherical or melco-shaped tip, which can rotate and immediately swing in the support housing on the corners. The hull is fastened with bolts or pressed against the lever.

In modern nodes, as a rule, an unbeling structure is applied, where the housing is rolled after the installation of the finger. Plastic or other liners are placed between the finger and the case. They work like a sliding bearing and capable of providing rotation with minor effort. For domestic cars use other ball supports that are called collapsible. Lufts are eliminated with a lid suspender.

As a rule, all components of the ball support are made of steel. To reduce friction between the stroke surfaces, the surface of the spherical recess is covered with polymers, for example, plastic. However, there are ball supports in which the polymer coating is absent (as a rule in domestic transport).

purpose of car support

The ball support provides reliable and rigid mount, while maintaining, while the limited mobility of the levers is regarding the wheel hub. When the driver moves by car, the front wheels have two functions - to ensure the movement of the vehicle on the road and provide the possibility of maneuvering (turns to the right, left). To move and maneuver correctly, the wheels should be properly positioned relative to the road, that is, free to roll forward and backward, it is smoothly standing, easy to control with the helm, and also, firmly attached to the axis. To satisfy these requirements, a suspension was developed, in which the hub of the controlled wheel and the suspension levers combine the ball supports.

The design of the multi-section front suspension includes two ball supports - the lower and the top - on each side of the vehicle (only four, but there are six more and eight).

Causes of breakdown ball supports

During operation, ball supports are susceptible to very serious loads. Depending on the design of the suspension and the location of their installation, the supports withstand constant blows when driving along an uneven road, as well as, carry a huge part of the entire mass of the vehicle. The main reason in violation of the correct operation of the ball support is the wear of contacting surfaces, which is capable of leading to an increased gap in the distance from the body to the finger. As a result - finger and rotates, and dangles in the case.

If wear is excessively strong, even not heavy loads on the support are able to lead to the end of the finger from the case. As a result, the support may not keep the wheel, and the vehicle is simply collapsed on the asphalt.

The main signs of wear of the ball supports are:

- Uneven wear tires on wheels.

- As a result of the fact that the front wheels are wagged, the vehicle is unstable to

Direct trajectory.

- If an effort is increased on the steering wheel, and when it is turned, the creaking of the car is heard.

- When driving at low speed on uneven road surface, a knock is heard.

The increase in the gap appears as a result of the following factors:

- In the hinge there is no lubricant (if its presence is necessary).

- If a bustker is broken or a protective case, which is why water and dirt enters the gap, which significantly increases corrosion, as well as abrasive wear.

- With increasing dynamic loads with rapid motion on uneven road surfaces.

- Natural wear with outdated materials.

Independent diagnostics of ball support

To find out what state is a ball support, you need to:

- Option first. Raise the wheel with a jack. Next, grab it with both hands for the bottom and the top, and then as much as you can take it stronger to feel if there is a backlash or development in connections.

- Option second. This method is more accurate. Take the mont or a piece of thick wire and climb the vehicle. Then set the rod in the middle of the lower lever and the edges of the support, and then pull up. The essential course of the mount either the rod will testify to the presence of a backlash.

- Option third. If the previous options did not help you or did not fit, do the following. Fully remove the ball support and carefully inspect whether there are damage and defects on it. Next, hold down the support in the vice, and then check the ridial and axial backlash of the ball finger. If it (finger) moves without effort, this is a clear sign of a malfunction at which it is necessary to replace the ball support. This method is the most accurate of all described, however, the most time consuming. Experts recommend using it.

Repair of ball support car

There are several ways to repair the ball joint. For most cars replacing support with lever is an expensive pleasure, because it costs a lot of this lever. There are also cars with a multi-link suspension. The cost of the works for the lower arm is quite high, and for the top - twice. Therefore, most car owners prefer to repair the ball joint, rather than replaced, because it costs half the price. In addition, repaired ball bearing becomes more resistant to wear and typically has a greater resource generation, rather than a new support.

To restore the ball joints using the following technologies:

- The most simple - alteration of the ball joint in a collapsible, polishing finger and change plastic liners.

- More laborious - pressure housing is filled with liquid polymer. Then, the polymer solidifies in the gaps. Molded support is removed and changed with new, not original ball bearings.

replacement of the lower and upper ball joint

The process of changing the lower and upper support has no differences. From the tool you will need:

When the ball joint replacement, first lubricate a new bearing lithologic, which should remove the duster and apply the optimal amount of grease finger. Then anther back dress.

- Tear fixing bolts before the car will be like poddomkrachena, but it is not necessary to unscrew them completely.

- Lifted by jack the vehicle and remove the wheel.

- Next, unscrew the nut and ball stud bolts of the steering knuckle, which secure it to the support.

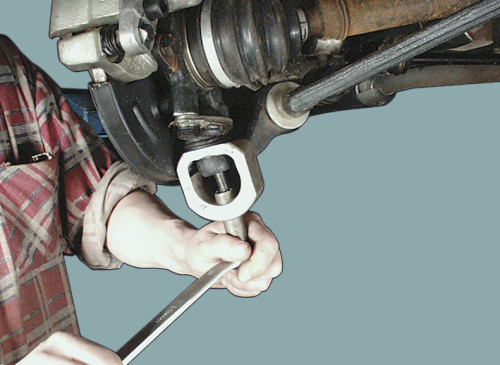

- Then, using a stripper finger raspressovyvaem.

- To follow up you need an assistant. He needs to press the lower arm by means of scrap or mount, then remove the old support.

- Next fasten a new ball joint to the steering knuckle. Assistant task - to gently and release the lever slowly, directing the eye to the finger.

- Then tighten the nut left ball stud and replace the ball joint can be considered completed.

Useful advice

The service life of the support, often depends on the mass of factors and on average ranges from 15 to 120 thousand kilometers. The life of the ball support is capable of cutting even a minimal crack in the flesh. Through her in the hinge can penetrate water, sand and dirt. To prevent breakage of the ball support, the state of the rubber protective cover should be monitored. It is advisable to do it on the overpass or the observation pit.

In order for the ball supports longer to serve, it is necessary to carefully ride the broken road surface and change damaged anthers in time. Do not forget that any mechanisms and vehicle components require regular care and repair. More information about replacing ball supports you can learn from this video.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments