When operating the vehicle, it is often necessary to replace its some components. It is necessary not only to systematically refuel the car, control the level of the brake fluid and the state of the brake pads, and regularly take care of its elements.

One of these elements, inconspicuous, but very important is the generator brushes, which perform a major role in the entire vehicle mechanism, because they control the current redirection. That is why you should pay attention to their condition and, if necessary, to replace them in a timely manner.

Content

The brushes of the generator, where they are, what work is performed

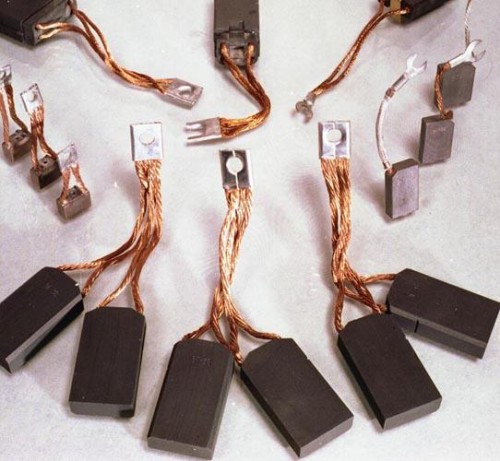

The generator brushes are elements of the alternator and are designed to remove the resulting voltage. They are made of special graphite, as a result of which they are called "coal." These brushes are used not only on transport generators, and in a variety of other electrical machines, for example, motor. Such motors are used everywhere: from elementary machines to complex lifting mechanisms. Regardless of the type of design, brushes are a rather important node, as a result of which their presence is necessary for the work of any equipment.

Once there was a single standard for the manufacture of brushes for automotive generators. The brushes with the EG-4 marking were a vivid example of this. They had normalized parameters, and their use was allowed in fact on all automotive generators. The second stage of the development of brushes became the brushes of the EG-61 generator. All the material was impregnated with special components to increase their strength.

To date, there are many generator brushes, which differ from each other for purpose and configuration. You need to choose this item considering the principle of the generator itself. Most of the electric motors need conventional brushes with standard characteristics, however, they are not too reliable and durable, because of which it is often necessary to replace them as a result of rapid wear.

If you do not replace the brush data in a timely manner, the generator and other mechanisms will suffer. Often the choice of car owners falls on the most strong models or on brushes impregnated with a special solution, which protects them from rapid wear. For example, special graphite components should be selected for high-speed electric motors, which are adapted to special conditions.

Generator brushes, generator brushes sizes according to norms

Designers produced the required resource of this part. At the moment, it is approximately fifty thousand kilometers. Some compare such a distance with four years of operation of the vehicle.

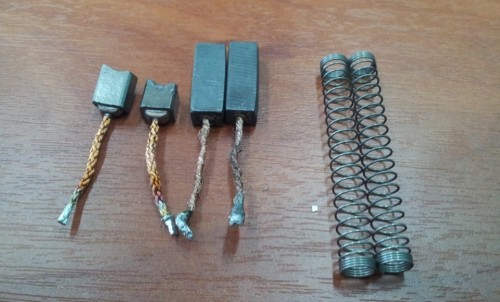

In addition, there are certain norms that regulate the permissible size of these brushes during operation. The generator brushes are prone to erasing, because in the process of operation have constant friction with the collector and decrease in size. So that they constantly come into contact, the springs are provided that ensure their dense contact, even if they erased. However, over time, their length is limited, and the springs can no longer provide the density of contact.

To diagnose whether it is necessary to replace the brush, it is necessary to visually estimate its length. As a rule, the norm is considered when the brush protrudes from the nest to five millimeters and more. If this parameter is underestimated, the brush must be replaced.

Generator brushes do not work, fault signs

When carrying out a variety of events that are related to the service of the vehicle, different small elements attract very little attention to themselves. The generator brushes are not an exception, the malfunction of which almost always comes suddenly.

Before opening the hood and remove the counter node, the following features will be indicated about the fault of the brushes:

- Reducing the on-board network of cars. If a voltmeter is provided on the dashboard, its testimony will not correspond to the norm - the voltage in the network will be less than twelve volts.

- Sources of light work poorly. For example, the lighting lamp of the cabin or headlamp will begin to acquire low shades when working.

- The strange behavior of electrical consumers of transport is a decrease in performance, possible shutdowns. As an example, you can again name the lighting lamp or an electric fan motor that works too slowly or with interruptions.

- Fast battery discharge. The stress removed from the brushes becomes smaller and is not enough to charge the battery. As a result, many consumers use a portion of the battery energy having a limited capacity, and later, the battery sits.

- The last and most apparent feature is the inclusion on the instrument panel of the corresponding lamp. It suggests that the battery does not receive food and the diagnosis of generator details is needed.

Replacing the generator brushes, step by step instructions

- Open the vehicle hood and find the location of the generator. As a rule, it is installed not far from the crankshaft and are attached to the motor itself.

- Disconnect the minus terminal from the battery.

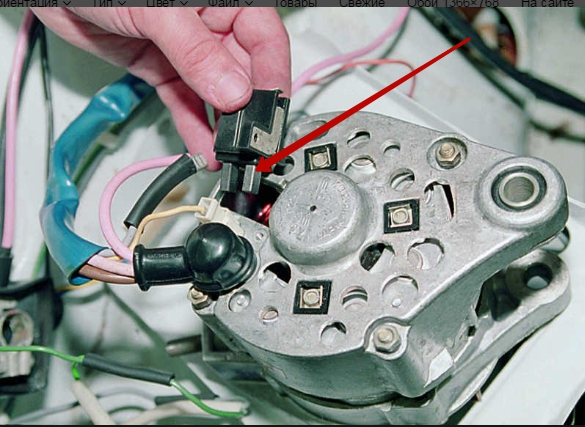

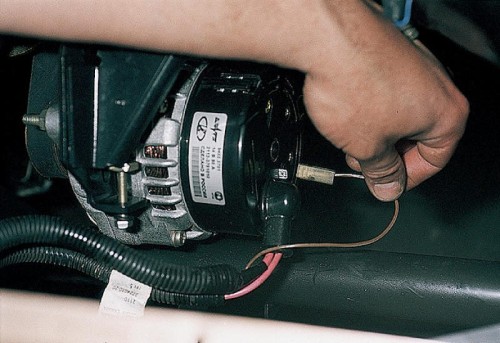

- On the generator, pull out the plug with the wires, which are mounted in the "tablet" of the brush node. On cars old models, it is not provided for the presence of this "tablet", but they have a plug itself.

- We unscrew the screws on which the brush node is completed, then pull it out. During the execution of this operation, the brush holder should be a little bending, because the brushes will not allow him to freely get out of the landing place.

- We carry out the selection of seating and mounted a new product into the nest. To do this, press the finger to the brush to the brush holder and go to the node in the socket. As soon as they are inside, you can let them go. Then check their contouring density with the collector.

- Now tighten the screws fastening screws.

- Insert the plug with the wires back into the connector.

- Install the battery terminal.

Tips of professionals

To avoid unnecessary onboard electronics problems, conduct diagnostics and replace brushes in a timely manner. This will ensure uninterrupted work of the vehicle and will save you from unexpected troubles on the road.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments