Modern car owners are accustomed to a huge number of tire workshops that provide their services actually at every corner. But, unfortunately, the developed tire service is characteristic of large megacities, and so-called "bearish corners", where there are no workshops for several kilometers, we have plenty. Of course, in this case, the spare keeps can be avoided, however, it often happens that two wheels are penetrated simultaneously. Therefore, even theoretical knowledge of the tire terminal can be useful to any motorist. About this further in the article.

Content

- How to batte with towing cable and jack

- Tools, fixtures, consumables for the manufacture of a tire machine

- A tire machine, how to make it do it yourself, in detail

- Disassembly of tires with a tire mounting machine, stages

- Installation of tires, phased

- Recking Council: The less the corner of the welding of the tip to the gauge to the lever, the easier it is the work, the machine is better to attach to the floor of the garage. When boring, do not forget to use soap mortar.

- How to unfold the wheels by hitting the wheel

- Determination by shock method with mounting corner and sledgehammer

- Limiting with an unstressed way using a jack

- Entry with two durable boards

- Special devices for tires on the road do it yourself

- Tips for facilitating work when laying

- How to find and order tires and jack at a rough price and free shipping

How to batte with towing cable and jack

- We dismantle the wheel and clean it from dirt.

- We produce air from the wheel and put it up with the nipple.

- We skip the towing cable through the hole in the disk.

- We put the jack on the sidewall of the tires as close to the rim. If the tire with the camera should not put the jack opposite the nozzle, otherwise there is a chance to tear it from the camera.

- We throw the cable to the bracket or the platform for lifting the jack and fix the cable ends among themselves.

- Rotate the handle end of the jack drive in such a way that it pulls up the cable, and the base displaced down the landing ring, resting in the sidewall of the tire.

- As soon as this side of the tire separated from the disk, go to the next procedure.

- If you only need to change or repair the camera, then acting alternately by two installations, raise the sidewall of the tires near the fitting at the end of the rim.

- Press the fitting inside and remove the camera from under the tire.

- We take out the nipple from a good chamber and squeeze air from it.

- To install a good chamber, reject the sidewall of the tire and insert the fitting from the inside into a special hole intended for it. Then put the camera under the bus.

- In order for the tire when installing the tire, it is slightly screwed it, without inserting nipple.

- After the gauge insert the nipple in the fitting, pumped and install the wheel in place.

Tools, fixtures, consumables for the manufacture of a tire machine

- Drill.

- Welding machine.

- Lathe or bulgarian with enroll and petal circles.

- Steel pipe of rectangular cross section.

- Two-duct round of the circular section (height of 1.5 meters).

- Kosinki in the form of rectangular triangles (thickness of 5 millimeters).

- Old hub.

- A piece of steel sheet (thickness 4-5 millimeters).

- One-memeter steel pipe.

- Steel rod (diameter of 20 millimeters).

A tire machine, how to make it do it yourself, in detail

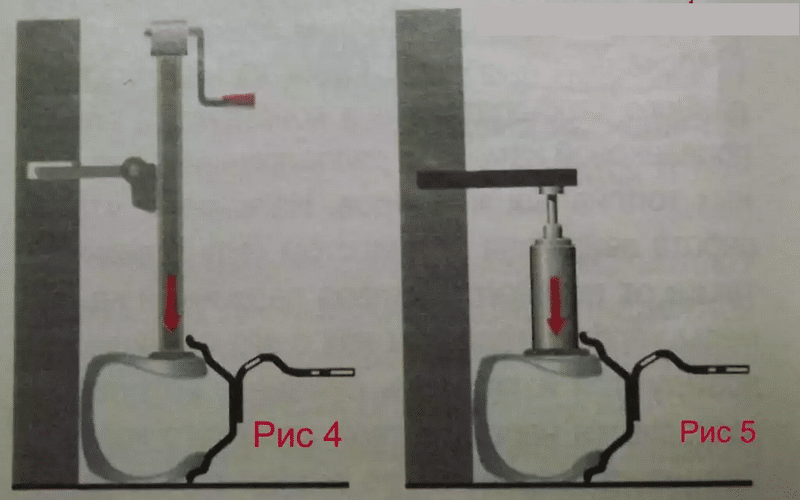

In this case, the tire locking machine consists of two tools: devices of the beading and the actual tire mounting machine combined into one.

The bottom frame of the machine H-shaped 90 × 60 centimeters produce from the steel pipe of the rectangular cross section.

To the jumper at a right angle of thirty centimeters from the edge, we weld the two-link pipe of the circular cross section with a height of about one and a half meters. The place of welding is enhanced by brazers in the form of rectangular triangles with a thickness of five millimeters. For fastening the wheel on the pipe we put on the old hub and weld to it. The height of the hub installation is chosen under human height, so that the wheel lying on it was about the belt.

It is necessary that the pipe towers over a cylinder is at least thirty centimeters, and did not interfere with work. A bit below the hub weld the bracket for fastening the upholstery adaptation. It can be made from a piece of steel sheet with a thickness of four or five millimeters, drilled in it a special hole under the bolt.

The device tool to be perfectly visible in the picture. The pipe for the manufacture of this node is worth taking the sewn - a long lever should be inserted into it. The lever for mounting and dismantling tires is made of a steel pipe with a length of about one and a half meters. Tips for it are made from the steel bar, the diameter of which is twenty millimeters.

The lever length can be made another, it all depends on the size of the free area in the garage and the strength of the hands. It is advisable to make the lever tips on the lathe, however, they can also be chopped up using a grinder with a credit circle, and then polish the lobe.

You can see the sizes of the tips in the pictures.

Disassembly of tires with a tire mounting machine, stages

- Clean the wheel from dirt and remove the nipple from it.

- Rubber mat on the base of the machine under the pen lever so as not to scratch the disk, then put the wheel on it.

- We raise the female leg and install it on the sidewall tires tight to the rim.

- Lubricate the buses of the tire with soap solution.

- Insert the lever into the bunch tube.

- Pushing down the lever, beat off the tire board throughout the wheel area.

- We do the same on the other side.

- We put on the wheel and screw to the hub with bolts to the hub.

- With the help of the assembly, we raise the tire boarding board and insert the straight tip of the lever under it.

- Lubricate the edge of the rim, boarding board and the tip of the soap solution.

- I pull the lever on yourself, resting them into the pipe over the wheel, while the tire board will be removed from the disk.

- We take out the camera from the tire.

- With the help of the assembly, we raise another board, we bring the lever under it and remove the tire from the disk, acting in the same way as described above.

Installation of tires, phased

- Lubricate a soap solution of the mounting tip of the lever, the edge of the rim and planting of the tires.

- Piece of planting boards put on the disk.

- The mounting tip of the lever is inserted between the disk and the part of the landing board. The ball of the tip must rest in the disk, the boarding board should be about the middle of the tip.

- I pull the lever towards yourself, resting them into the pipe over the wheel. At the same time, the board of the tire will be put on the dial of the middle of the mounting tip.

- When you wear the first side of the tires on the disk, lubricate the upper boarding board with soapy and we do the same with it as with the bottom.

- When you put the top of the tire on the drive, you can pump the wheel.

Recking Council: The less the corner of the welding of the tip to the gauge to the lever, the easier it is the work, the machine is better to attach to the floor of the garage. When boring, do not forget to use soap mortar.

The smaller the angle of the welding of the tip for the gauge to the handle, the easier the rubber is put on the disk. However, do not overdo it. If this angle is very small, then the lever will touch the lever and scratch the disk, so you look for the optimal option.

Since the machine is very easy, it is necessary to attach it for comfortable work to the floor. If the wooden floor is in your garage, attach the base of the machine to it with the help of self-tapping screws. If the floor is concrete, make a number of holes in it, where to install the anchor bolts for eight and pour cement mortar.

To make it easier to work, and the rubber and disks were not harmful, mandatory lubricate the tire board, wheel drive and lever tips with soap solution. In addition, you should not work with a dirty wheel, you should always be started with its cleaning.

To repair wheels that differ from your number of mounting holes, as well as the distance between them, you need to make adapters with studs. They are made from metal thick one centimeter.

How to unfold the wheels by hitting the wheel

The main difficulty in the process is due to the fact that even its own weight of the car owner is not enough to create an effort on the branch of the tire from the board, which may affect the loss of the elasticity of rubber.

Even the recruitment of the machine is applied to the separation. For the load distribution, a wide and robust board length is approximately 1-1.5 meters long. The disadvantages of this unstressed way are based on the fact that the rubber sometimes deteriorates. It is desirable to perform this event together to adjust the effort and velocity of the car. This option is perfect for those who wish to learn how to independently unfold the wheels of the car, however, its vehicle is on the go.

Determination by shock method with mounting corner and sledgehammer

The most common method is shock. It uses a massive sledgehammer and mounting corner. This method used all workers of tire plots and car owners before the appearance of mechanized devices. In the corner you need to bind all the problematic surfaces that can damage the tire.

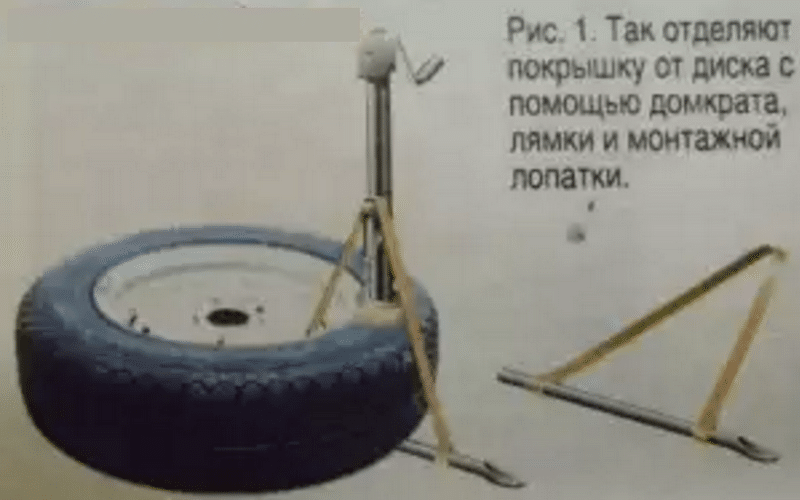

Limiting with an unstressed way using a jack

In many unstressed methods, an effort, a developing car jack, is used. In some ways, even the structural features of the jack and its type are not important. In road conditions, a car can serve as a footpoint. Fixing the jack and setting it to the point of exposure, we make a force until the desired result will achieve the desired result. It is necessary to abide care, so as not to break the device.

Without the participation of the vehicle for the lifting, in addition to the jack, durable straps, as well as a reliable metal rod, replaced which can be replaced by a mounting blade or long horn key. First, under the wheel, put the duct with the fixed loop. Under loop with straps, a jack is supplied, which is installed on the picking point. When stretching the plank or riding rod, there is pressure on the contact site.

If it is assumed to independently unfold the wheel at home, you can mow in the capital garage into the concrete wall, a rather hard lever of the channel, pipes or other construction profiles. Such a cantilever beam will provide reliable emphasis for the jack.

Entry with two durable boards

You can do without capital restructuring, using a pair of durable boards. Use them as a lever, which presses on board the wheels. Due to the difference in the length of the shoulder, there is an effort on the substrate, which breaks the rubber from the place.

Special devices for tires on the road do it yourself

There are special devices for this event on sale. Some models are pretty bulky for their constant transportation in the trunk, but, very effective in work.

Tips for facilitating work when laying

The most convenient point to start the election is the opposite spool side. Before starting the event, you can pour out a slightly auxiliary fluid WD-40. Just a few minutes, the liquid will pass into all the hard-to-reach places and solurate a certain amount of problem material. As practice is evidenced, it does not create aggressive influence on rubber.

How to find and order tires and jack at a rough price and free shipping

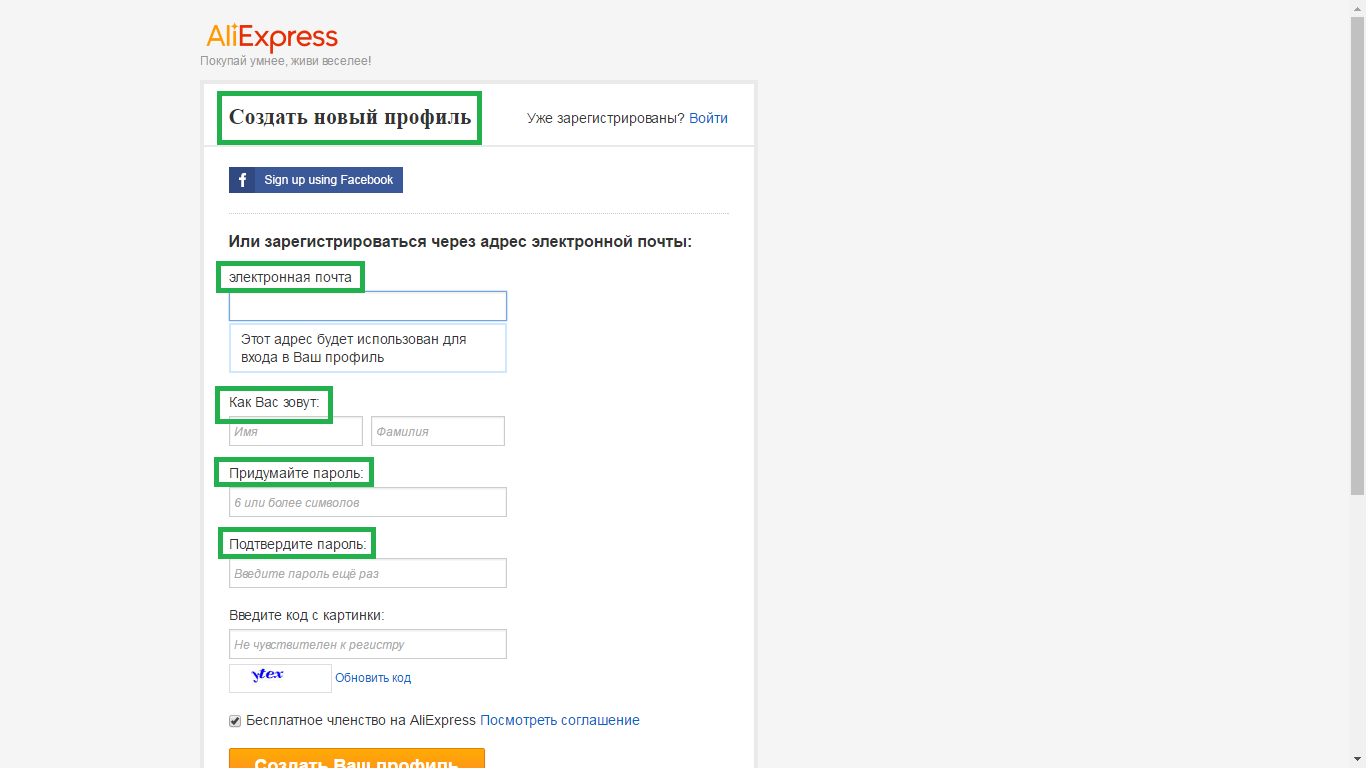

- We are registered. If you are already registered on the site, just log in to your profile.

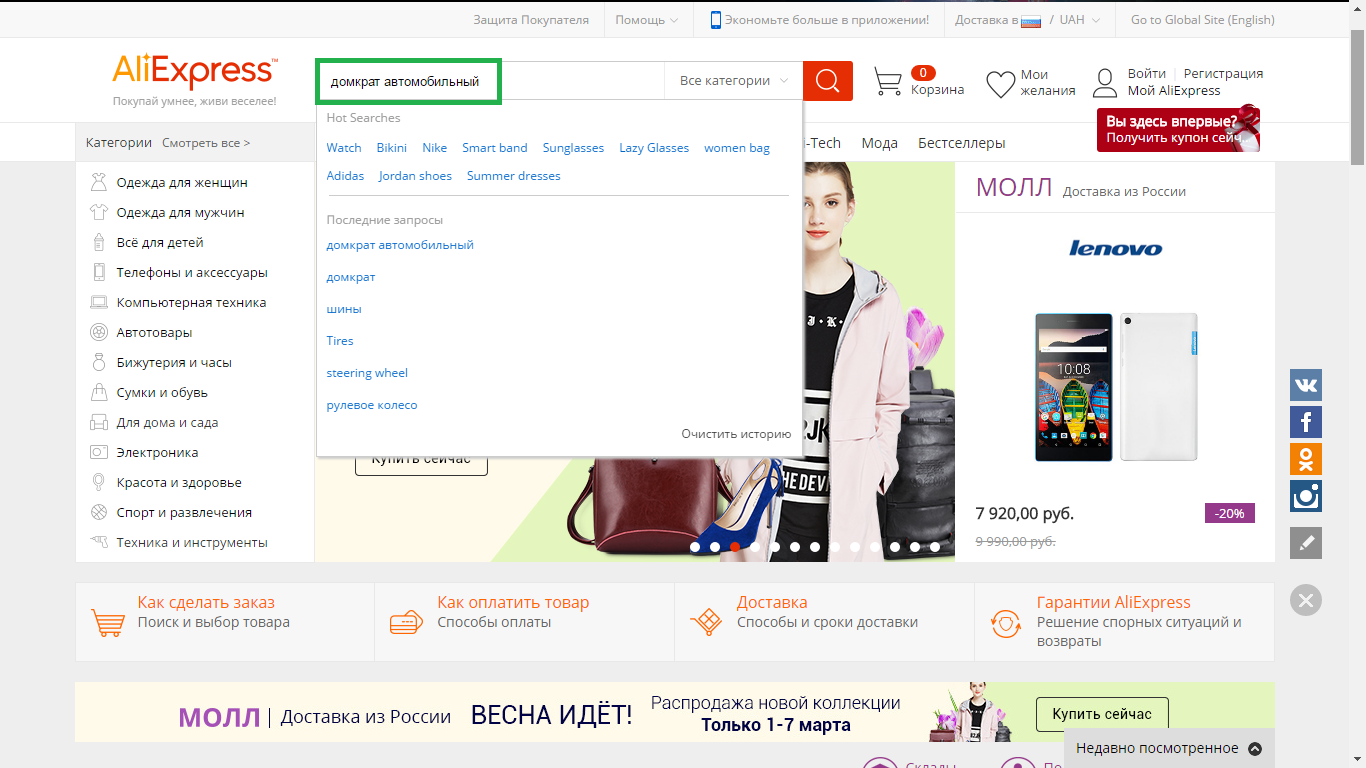

- In the search bar, we enter the name of the desired product, for example, car jack.

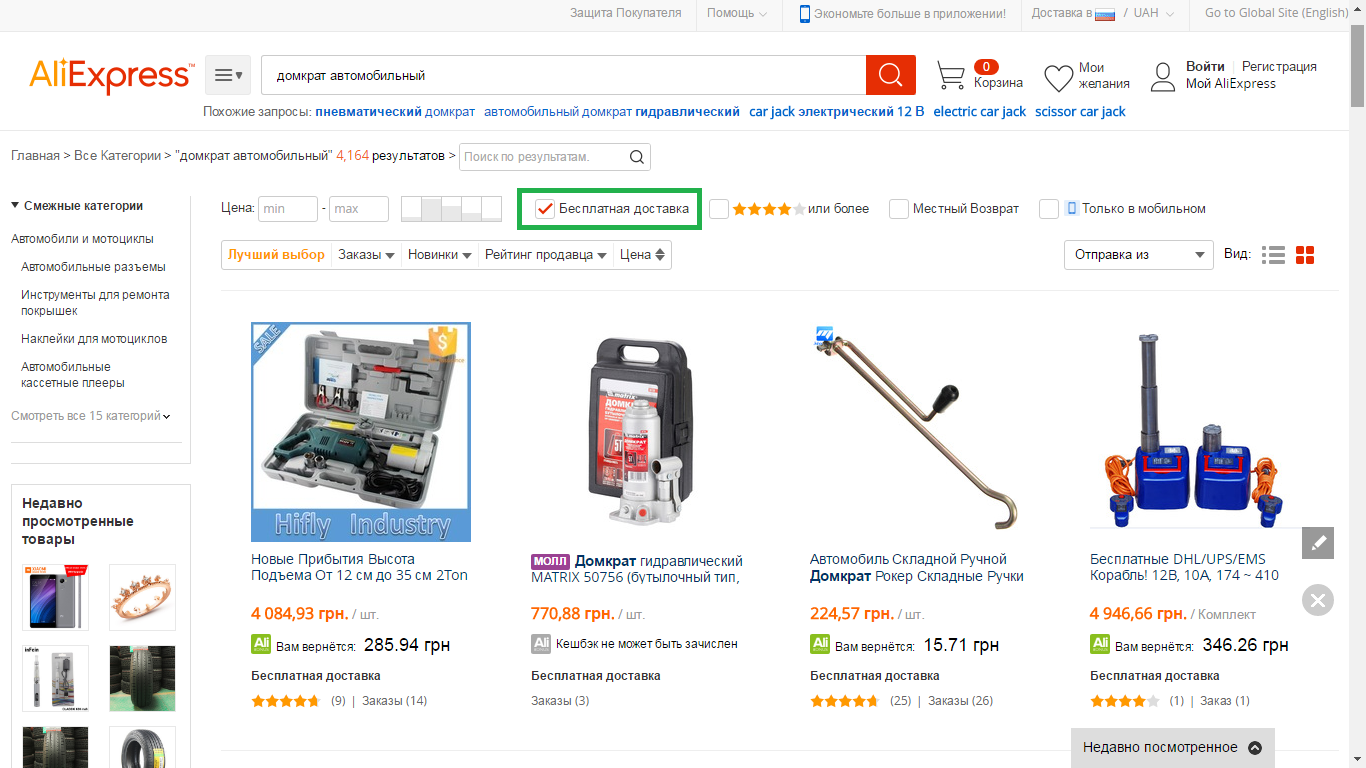

- Choose goods with free shipping.

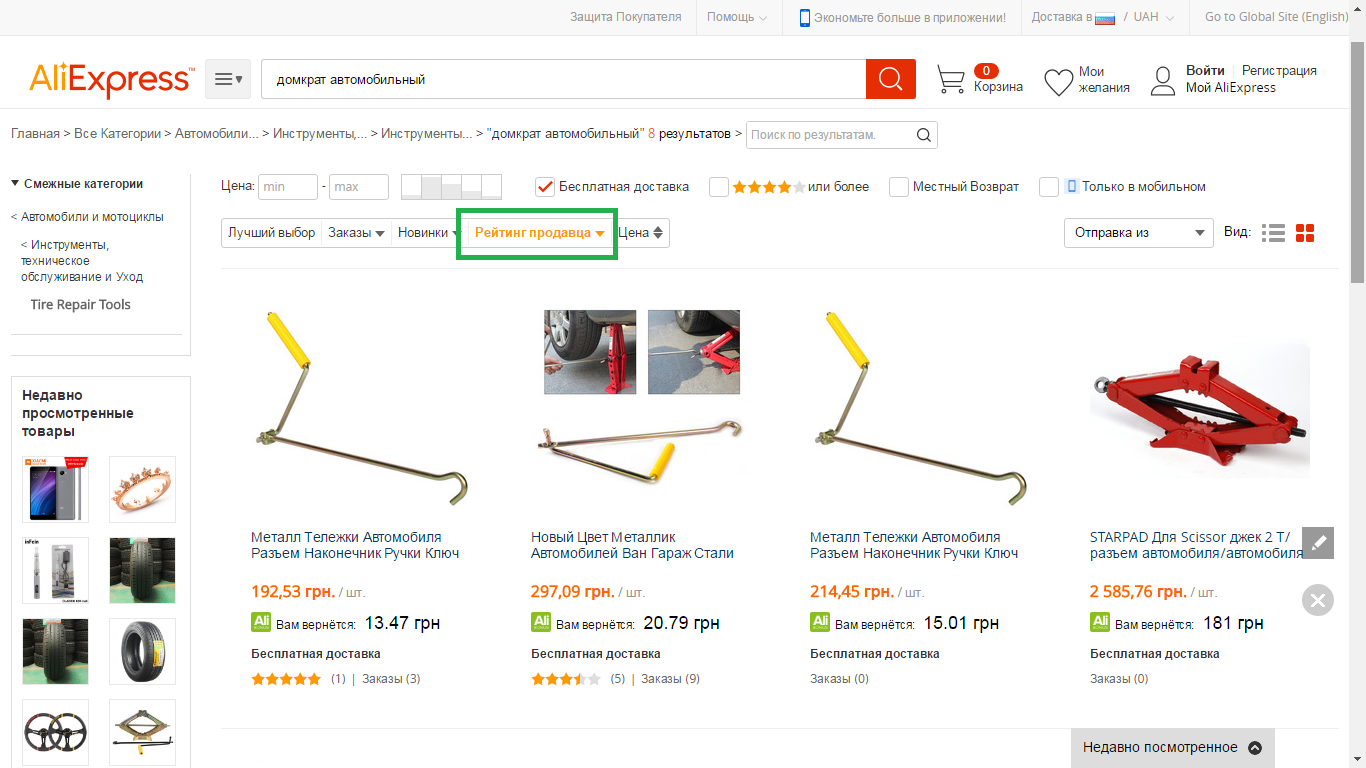

- We sort the results by the seller rating.

- On the product description page, choose the desired number and click "Buy Now".

- Fill the shipping address and pay for the order.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments