Vehicles produced today are becoming increasingly intricate in technical terms. It is well affected by driving a car that is becoming increasingly comfortable. It is difficult to imagine, however, such a device as a synchronizer was not always present in the automotive checkpq. Earlier, the gear shift had to use double clutch squeezing. First, the grip squeezed to disconnect the gearbox with the crankshaft, and then, on the contrary, for their connection. However, time is coming. Mechanics and mechanical engineering stepped into the future. The appearance of the synchronizer of the PPC significantly increased the service life of the CAT as a whole, as well as its separate components. It is more convenient to control the vehicle has become both the driver. About this further in the article.

Content

Synchronized gearbox that means

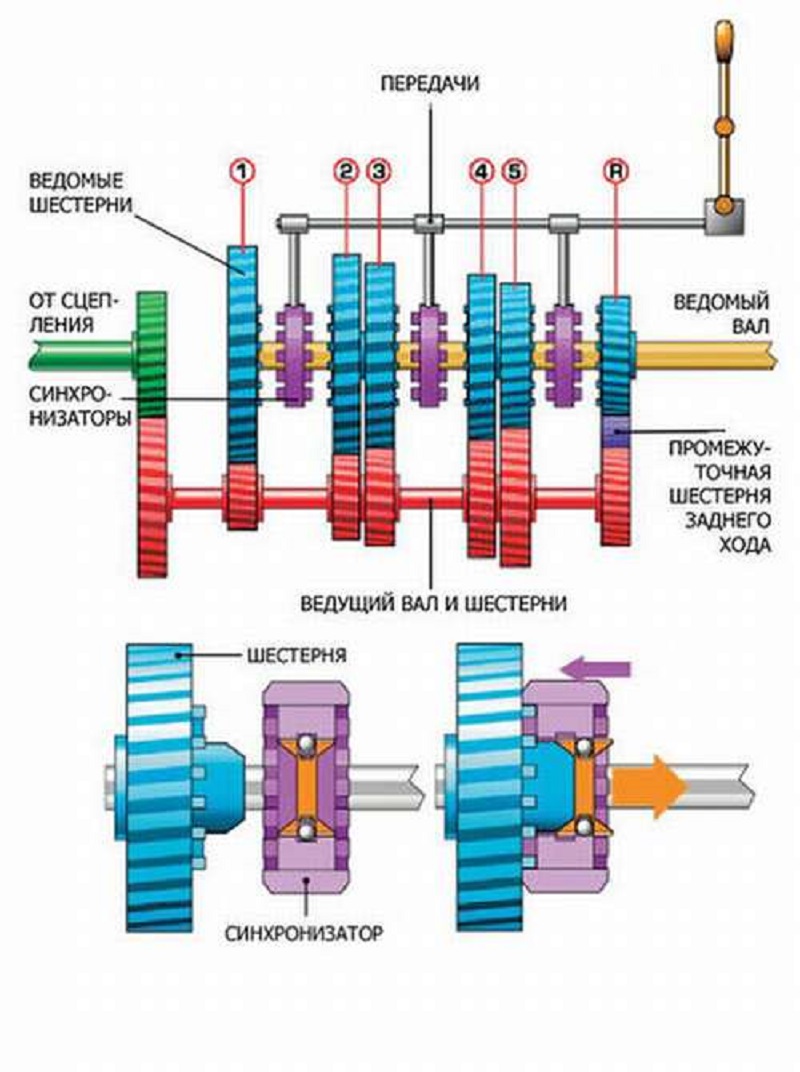

Nowadays, actually all mechanical and robotic boxes are synchronized. To turn on the speed in the boxes of this type, a prerequisite is the alignment of the speed of rotation of the gear and shaft. Synchronization provides such a device as a synchronizer. In addition to smoothly switching speeds, it is able to reduce the noise when switching speeds, reduce the wear of the mechanical connection and, thus, increase the life of the gearbox. Synchronizers are equipped with all transmissions of the PPC of the passenger vehicle, including the transmission of the reverse.

Synchronizer action principle

When the box lever is in a neutral position, the clutches of synchronizers occupy an average position, the gears on the slave shaft are rotating freely, the transmission of the force is not produced. When the driver chooses the necessary transmission, the plug moves the clutch in the direction of the gear. Together with the coupling, the shift of superstars affecting the blocking ring, which is pressed against the gear cone.

A friction force is created on the surface, turning the ring until the rings are stopped in the rings grooves (the ring will stop from turning). In this position, the blocking ring does not allow the synchronizer clutch to move along the shaft axis, since the ends of the clutch slots are located opposite the ends of the slots of the blocking ring.

Then under the influence of friction forces of the driven shaft and gears are synchronized. When the speeds are aligned, the blocking ring under the influence of the clutch slots turns to the other side, the clutch lock is removed, the clutch slots are freely pass to cling to the crown of the gear. The secondary tree of the KP is rigidly connected to the gear. Despite the mass of operations, the entire process of inclusion of transmission and synchronization takes a split of a second.

CPP synchronizer, device, design features

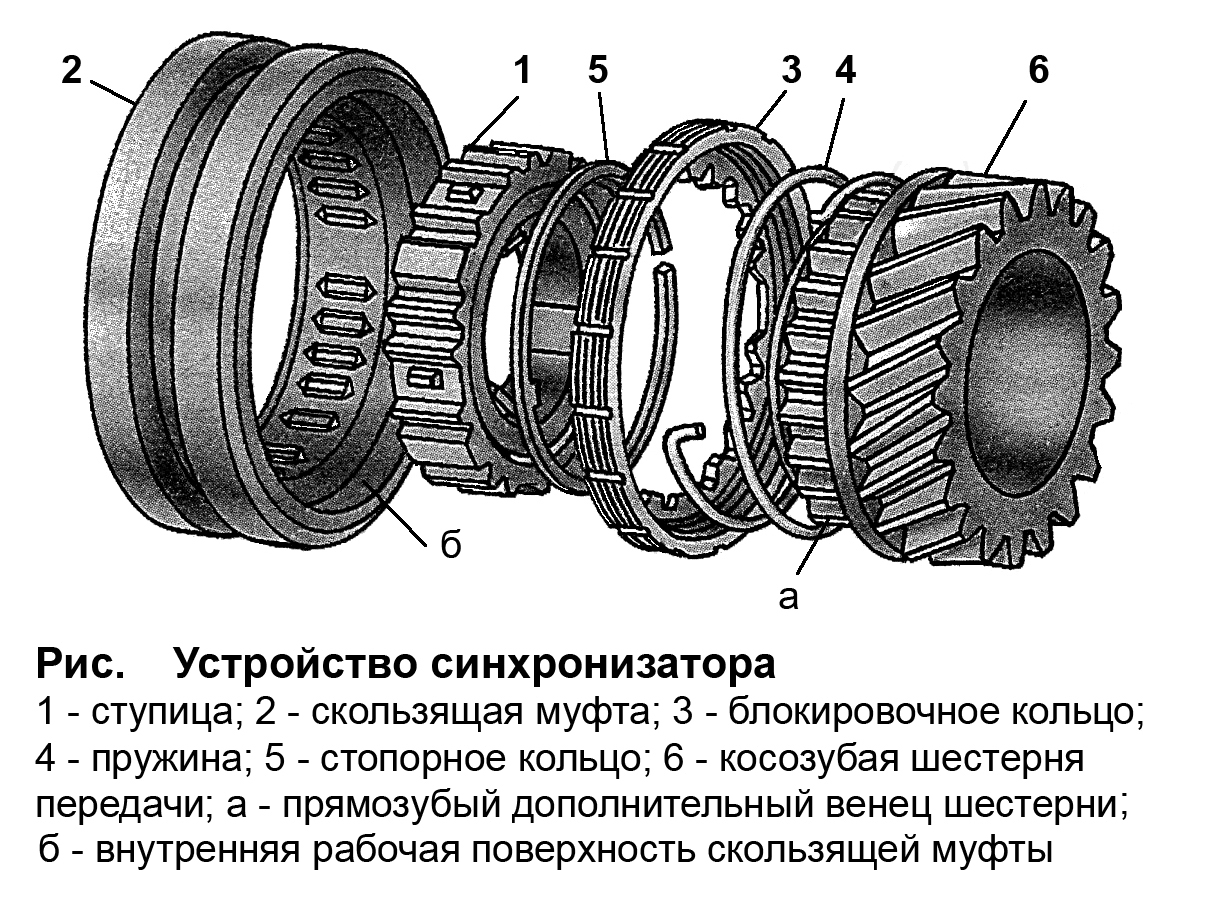

An integral part of any synchronizer is a hub that has special slots that are inside, with which it connects with the secondary shaft of the KP, allowing you to move in the axial direction. The external slots are designed to connect the hub with the inclusion coupling. Directly on the hub there are three additional grooves that are located at an angle of 120 degrees - they are crackers. They are spring-loaded and are intended for a more efficient clutch pin in the synchronization process.

The CP synchronizer clutch is designed to reliably pair the gear and shaft in the checkpoint. It is on the hub and is equipped with internal grooves. With the help of crackers and ring groove, both element data are securely connected. With the outside of the coupling, the coupling is already connected directly with the transmission fork.

The blocking ring is intended for pairing and does not allow the clutch to be closed until the speed of the shaft and gear will be identical. The inner part of the ring is made in the form of a cone and interacts with the friction cone, which is located directly on the gear.

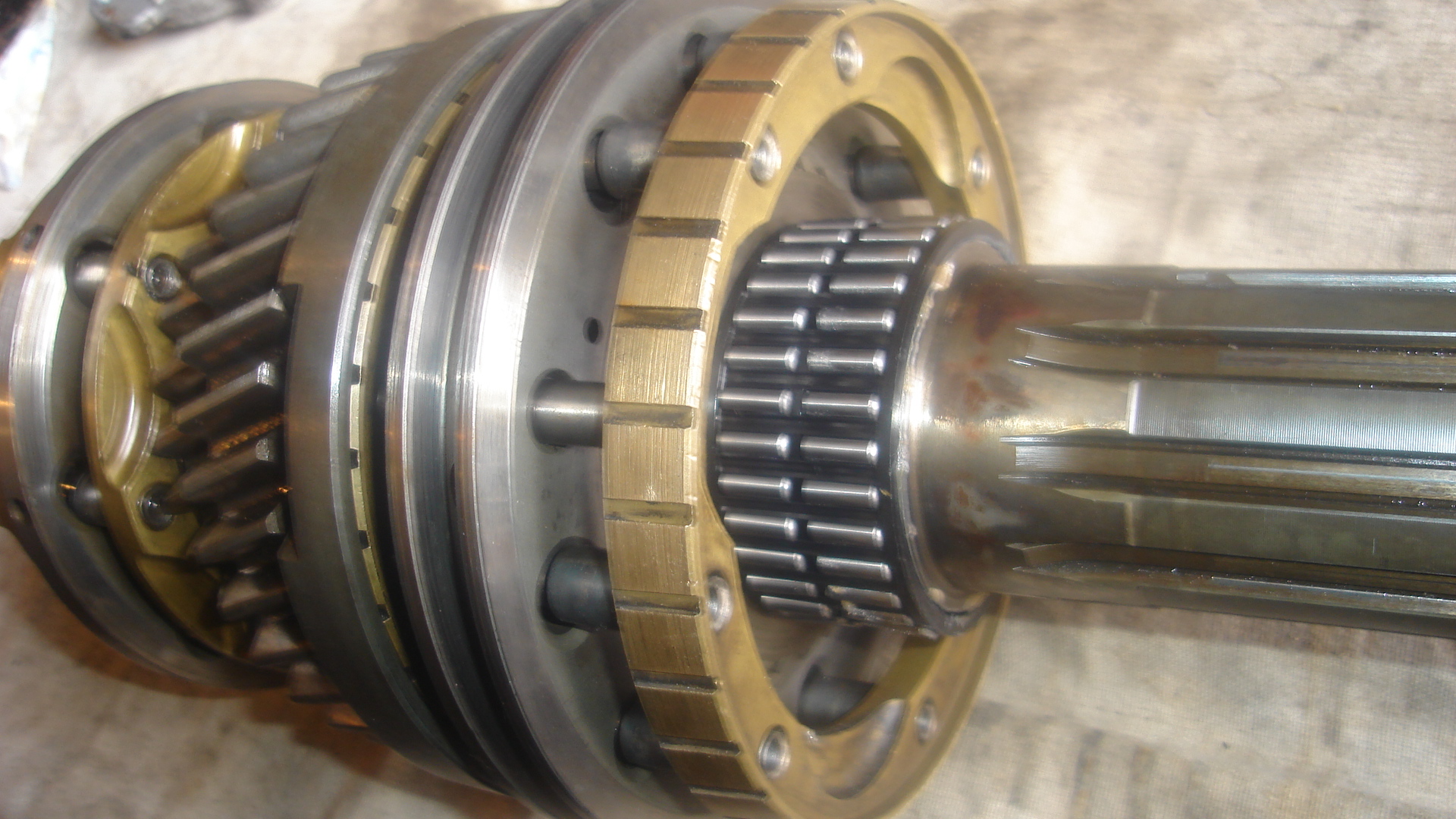

Multiconus synchronizers for which they are installed in the checkpoint

For transmissions to switch more smoothly, as well as to increase reliability, multiconus synchronizers are used, for example, two or three-digit. Variations with three cones are the most difficult, however, the most durable. They are mainly used in automatic robot boxes. They are also installed on some foreign cars.

Synchronizer malfunctions and ways to eliminate them

If there is any difficulty shifting, most of the car owners who have at least basic knowledge of the device and the principle of the gearbox, believe that the synchronizer is wines. It often turns out to be true, although the clutch malfunction should be predetermined, which also quite often cause problems in the operation of a manual transmission when the system functions with a certain intake and so on.

If the test did not detect violations, it is possible to suspect problems with a synchronizer by such symptoms:

- With spontaneous shutdown, first of all, it is necessary to pay attention to the switching clutch and gears that can be worn out.

- If noise appeared when switching the speeds, the identification of which is impossible and which used to be uncharactertene, this may indicate the curvature of the blocking ring or that its conical part is worn.

- Complex gear shift when you need to make great efforts and make several attempts, in fact guaranteed about the failure of the synchronizer.

Immediately it should be said that the repair of this device is extremely laborious and in fact unrealistic to fulfill it on its own. This will require professional equipment and a lot of time, so it is desirable to trust this business to specialists. In addition, it is worthwhile that it is quite often such a phenomenon, as the painting of the gear teeth, such a danger is most susceptible to the owners of the cargo transport and lovers of sudden starts from the place. Operation of such a box is invalid.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments