The CPP synchronizer is a mechanism that levels the speed of gears and shafts to switch the transmission. With the help of a synchronizer, the noise and mechanical wear of the elements decrease when changing the transmission, which increases the service life of the PPC. About this further in the article.

Content

- Synchronizer PPC 2110, device

- The principle of operation of the synchronizer

- CPP Synchronizer, Possible Problems

- Tools assistants, consumables and adaptations

- CPP synchronizer, how to remove it from the secondary shaft, step by step instruction

- CPP synchronizer, to pay attention to when inspection

- CPP synchronizer how to assemble

- Tips Profi, how to extend the life of a car synchronizer

Synchronizer PPC 2110, device

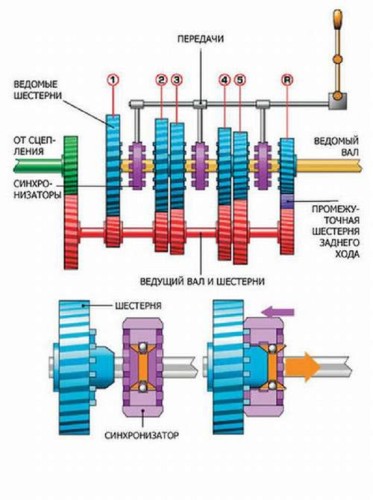

Synchronizers are mounted in passenger cars for all PPCs. They work on a specific principle - leveling the speed using the friction force. When the difference between the speed of rotation of the gear and shaft is large, the friction force should achieve a slightly larger level to synchronize their actions. This phenomenon is observed when the highest gear is turned on.

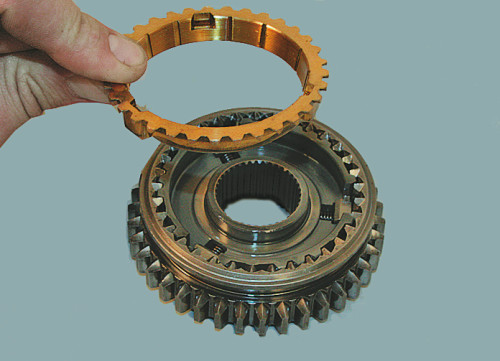

The main element of the synchronizer is a hub where the internal and external slots are provided. The inner slots are used for clutch with the secondary shaft and, with the likelihood of the axial movement of the shaft on various sides. The lower slots are thus connected with the inclusion coupling, providing a rigid grip of the gears and a gearbox. Outside the power coupling is connected to the fork for PP.

In addition, the KP synchronizer includes a blocking ring, which is necessary to ensure good synchronization and so that when leveling the speeds, the coupling does not close. Inside the ring there is a conical surface that is designed to exchange actions with a friction cone gear. And to create the conditions for blocking the inclusion coupling, slots are installed from the outside of this locking ring.

The principle of operation of the synchronizer

All the actions of the Synchronizer of the PPC occur for the fraction of a second. When the PPC lever is located in a neutral position, gears and clutches, do not transmit power flow and freely rotate. If you wish to increase the speed by switching the gearbox, the lever has a clutch towards the gear direction. In this case, the system happens in the system.

When you turn on the required transmission on the coupling, crackers are shifted (small shutters), acting on the blocking ring, which faces the gear cone. This activates the strength of friction, which turns the ring until it stroops, after which the speed of the gear and shaft is synchronized. As a result, the engine is configured to other turnover, and the driver can increase the speed without much effort.

CPP Synchronizer, Possible Problems

- If you hear the incomprehensible nature of the noise or crunch, it is quite possible that the blocking ring was deformed or a conical surface was worn.

- In case of difficulty shifting - wear of the synchronizer itself.

- If the transmissions are turned off spontaneously, the shutdown clutch is faulty or the gear was worn.

Tools assistants, consumables and adaptations

- Marker or chalk.

- Kerosene.

- Engine oil.

- Litol.

- Screwdriver with a sufficiently strong handle and flat blade.

- Passatia.

CPP synchronizer, how to remove it from the secondary shaft, step by step instruction

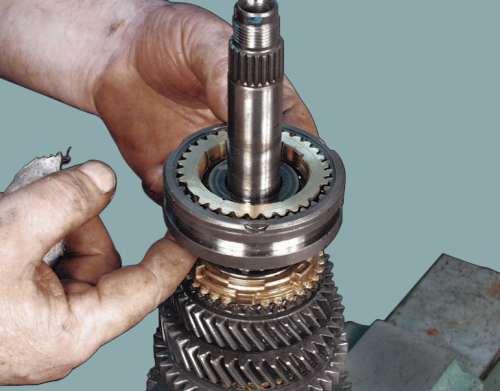

Before disassembly, you should first remove the synchronizer from the secondary shaft. At the very beginning it is very important to note with the help of chalk or marker location of the coupling regarding the hub. Next, carefully remove the clutch from the hub. It is necessary to remove it extremely carefully so that crackers with the balls do not scatter on the side under the influence of the springs. All extracted elements should be rinsed thoroughly in kerosene and decompose on a clean, non-lit surface.

CPP synchronizer, to pay attention to when inspection

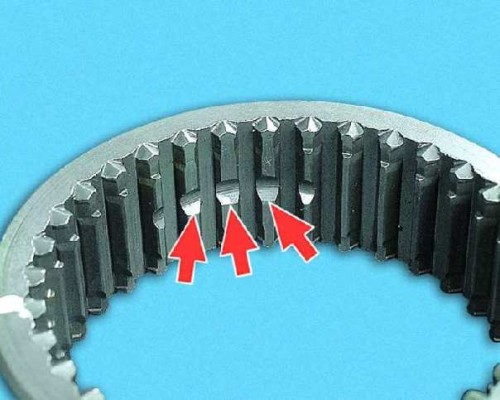

It is necessary to conduct a scrupulous and attentive inspection of all elements - hubs, slots, couplings (pay attention to the ends of its teeth) for the presence of slabs and chips.

In addition, no less carefully inspect all the springs, crumbs and balls - they should have an ideal physical condition, they should not have coarse traces or visible traces of damage on their surface. Springs should not be too compressed or elongated. It should also check the gap between the crown of the gears and the ends of the ring.

When defects are detected on elements, change them to new ones. However, if there are too many damaged items, it is easier to replace the synchronizer.

CPP synchronizer how to assemble

After the proceeding operations done, before replacing damaged parts, lubricate them with a motor oil. Install the clutch back to the hub, focusing on the previously installed mark. If the tags will match, then the groove on the coupling (three of them) coincide with the grooves of the hub. Next you need to smear the lithol spring of the retainer and paste it into the groove of the hub. Then it is necessary to put a ball into the hole in advance with a lithol crush.

With the help of a screwdriver insert the hub in the groove the hub with a ball, squeezing in advance. The scene on the sugar, at the same time, should turn out to be outside, and the spherical surface - turned to the coupling. When mounting a crush, the ball inserted into it should get into the special grooves on the clutch slots, for which it should push it deeper.

Using a screwdriver, send a spring into the reservoir hole. The remaining clamps should also be installed.

Tips Profi, how to extend the life of a car synchronizer

As a rule, rapid wear and breakdown of the elements of the synchronizer are due to coarse work with the PP lever. To extend the performance of the synchronizer and prevent problems with it, switch speeds should be smoothly, without jerks.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments