To date, the injection system is actively used on gasoline and diesel engine. It is worth noting that for each variation of the motor, a similar system will significantly differ. About this further in the article.

Content

- Injection system, purpose than a gasoline engine injection system differs from a diesel injection system

- Gasoline injection system, fuel injection system for gasoline engines

- Injection systems of gasoline engines, types of fuel injection systems, advantages and disadvantages of each type of gasoline engines injection systems

- Diesel engines injection systems, types of systems, advantages and disadvantages of each type of diesel fuel injection systems

- conclusions

Injection system, purpose than a gasoline engine injection system differs from a diesel injection system

The main purpose of the injection system (another name is an injection system) - ensuring the timely supply of fuel in the working cylinders of the motor.

In gasoline engines, the injection process supports the formation of an air-fuel mixture, after which its ignition is carried out using the spark. In diesel engines, the fuel supply is performed under high pressure - one part of the combustible mixture is combined with compressed air and almost instantly self-propagated.

Gasoline injection system, fuel injection system for gasoline engines

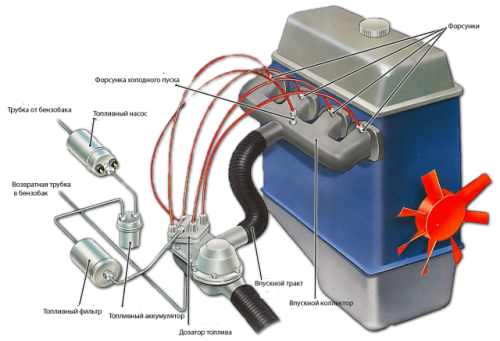

Fuel injection system is an integral part of the TC fuel system. The main working body of any injection system is a nozzle. Depending on the method of formation of an air-fuel mixture, there are systems of direct injection, distributed injection and central injection. Systems of distributed and central injection - pre-injection systems, that is, injection in them is carried out in the intake manifold, not reaching the combustion chamber.

Injection systems of gasoline engines can have electronic or mechanical control. Electronic injection control is considered the most perfect, which provides significant fuel economy and reducing harmful emissions into the atmosphere.

The fuel injection in the system is carried out impulse (discrete) or continuously. From the point of view of saving perspective, a fuel injection is considered to be used by all modern systems.

In the motor, the injection system is usually connected to the ignition system and creates a combined ignition and injection system (for example, Fenix, Motronic system). The motor control system provides coordinated system operation.

Injection systems of gasoline engines, types of fuel injection systems, advantages and disadvantages of each type of gasoline engines injection systems

In gasoline engines, such fuel supply systems are used - direct injection, combined injection, distributed injection (multipoint), central injection (monovosprysk).

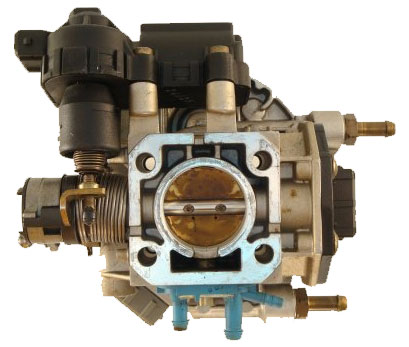

Central injection. The fuel supply in this system is made by means of a fuel injector located in the intake manifold. And since the nozzle is only one, this system is called another monofry.

Today, the central injection system has lost their relevance, so they are not provided in the new models of the car, but in some old vehicles they can still be found.

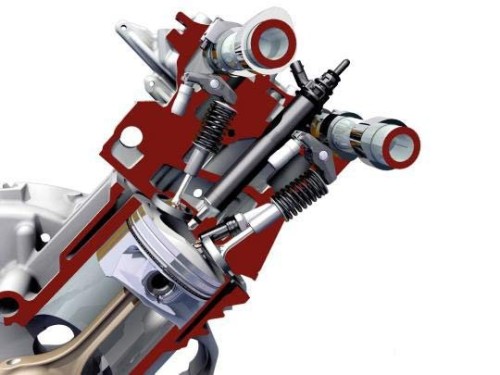

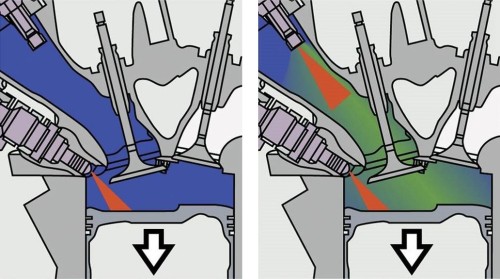

The advantages of the monofry are reliable and simplicity. By cons of this system include high fuel consumption and low motor ecology. Distributed injection. In the multipoint injection system, a separate fuel supply is provided for each cylinder, which is equipped with an individual fuel inlet. TVs, with this, occurs only in the intake manifold.

To date, most gasoline engines are equipped with a system of distributed fuel supply. The advantages of such a system are the optimal fuel consumption, high environmental friendliness, optimal need for fuel consumed.

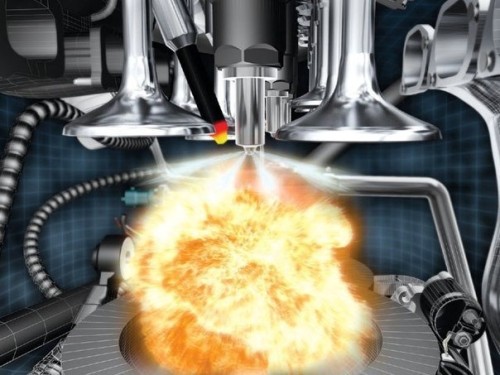

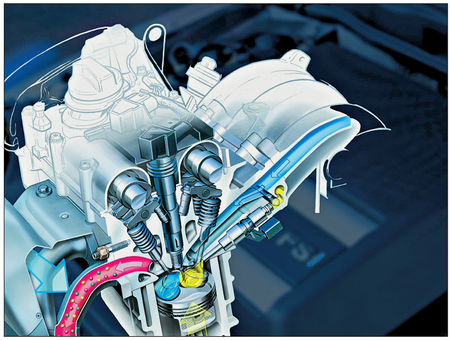

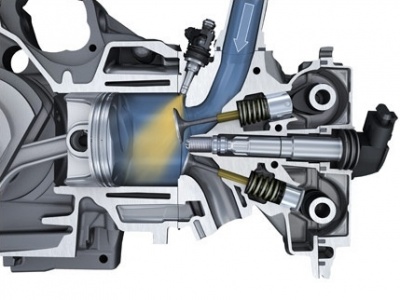

Direct injection. One of the most progressive and perfect injection systems. The principle of operation of this system is based on a straight (direct) supply of fuel to the combustion chamber.

The direct fuel supply system makes it possible to obtain a high-quality composition of fuel at all stages of the motor operation to improve the process of combustion of fuel assembly, increase the operating power of the motor and reduce the level of exhaust gases.

The disadvantages of this injection system are a rather complicated design and greater requirements for fuel quality.

Combined injection. Two systems are combined in the system of this type - distributed and immediate injection. As a rule, it is applied to reduce emissions of toxic components and spent gases, with which it is possible to achieve high motor ecology indicators.

Diesel engines injection systems, types of systems, advantages and disadvantages of each type of diesel fuel injection systems

The following injection systems are used on modern diesel engines - the Common Rail system, the system of pump-nozzle, a system with a distribution or row fuel pump of high pressure (TNVD).

The most popular and progressive are the pumps-nozzles and Common Rail. TNVD is the central component of any fuel system of diesel engine.

The supply of fuel mixture in diesel engines can be performed in the preliminary chamber or directly into the combustion chamber.

Currently, a preference is given to a direct injection system, which has an increased level of noise and less smooth operation of the motor in comparison with the supply to the preliminary chamber, however, it is ensured more important indicator - efficiency.

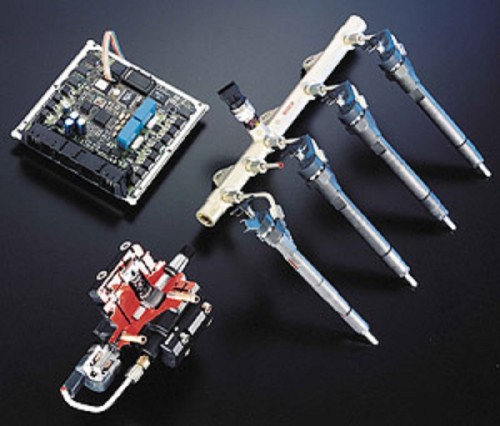

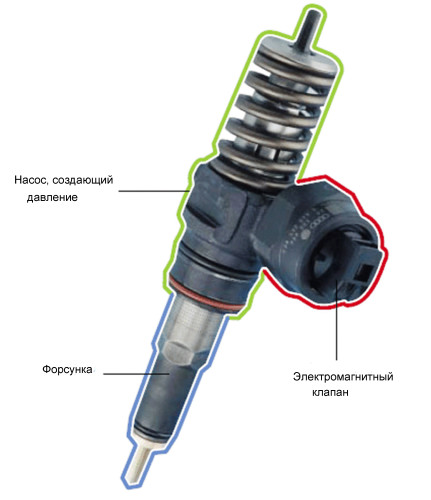

System pump-nozzle. This system is used to feed, as well as the injection of a combustible mixture under high pressure pump-nozzles. A key feature of this system - in one device, two functions are combined - injection and pressure creation.

The constructive disadvantage of this system - the pump is equipped with a constant drive from the motor camshaft (not disabled), which is capable of leading to rapid system wear. As a result, manufacturers increasingly prefer Common Rail systems.

Battery injection (Common Rail). More advanced combustible mixture design for a variety of diesel engines. In such a system, fuel is fed from the ramp to fuel injectors, which is also called a high-pressure battery, as a result of which the system formed another name - the battery injection.

The Common Rail system provides for the following stages of injection - preliminary, main and additional. This makes it possible to reduce vibrations and noise of the engine, make the procedure for self-ignition fuel more efficient, reduce harmful emissions.

conclusions

To manage injection systems on dieselms, the presence of electronic and mechanical devices is envisaged. Mechanical systems make it possible to control the working pressure, the moment and the volume of the fuel injection. Electronic systems provide more efficient control of diesel engines in general.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments