When the leaks of oil in the area of \u200b\u200bthe gas distribution mechanism appear, a periodic pressure drop in the lubrication system (a signal lamp turns on), it is necessary to ensure in good condition of the oil pump.

Removing the oil pump

For repair work related to checking the state of the oil pump, it must be removed from the engine housing.

Let's talk about it below.

Disconnect the minus terminal from the battery and drain the oil from the engine crankcase.

Next, take into hand the key on 10 and remove the protective casing of the gas distribution mechanism.

The toothed belt itself will have to remove, because the leading oil pump gear is driven by the timing belt.

IMPORTANT! After removing the timing belt, in no case turn the crankshaft and distribution shafts for the fastening bolts of their pulleys, as you can damage the valves.

Next, disconnect the wires from the crankshaft position sensor.

And now we need an assistant.

To unscrew the pulley from the crankshaft, ask the assistant to fill the engine flywheel with a mounting blade through a cap in the clutch crankcase.

Turn the pulley attachment bolt and use the pulley with two screwdrivers.

Next, you must remove the engine crankcase pallet.

Details stop at this point, it seems to us.

Note that for the convenience of removing it, unscrew the front cover of the clutch crankcase.

After removing the pallet, we turn to the removal of the oil pump. We turn over the three fastening bolts and remove it.

After disconnecting all the nodes and aggregates interfering with us, go to the removal of the oil pump directly.

Here, as always, everything is simple.

We turn into six bolts of fastening the oil pump from the gas distribution mechanism.

They are located radially on the pump housing.

Be careful and do not lose flat washers installed under fastening bolts.

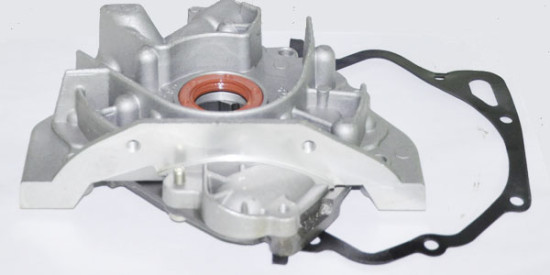

IMPORTANT! After each removal of the oil pump, do not forget about the replacement of its old gasket. And only the gaskets recommended by the manufacturer are subject to installation. Pasters of another thickness can disrupt the normal mode of operation of the oil pump.

Installing the oil pump

After making sure that the pump is configured or faults, install an old or new one.

Do not forget to lubricate the pump cavity to ensure the best suction of the engine oil from the pallet when the engine is first started.

IMPORTANT! The leading gear of the oil pump must be checked before the coincidence of its protrusions with a special convexity on the crankshaft. This is necessary for correctly installing the pump.

Lubricate oil pump oil oil oil.

If there are supervisors or cuts, replace it with a new one.

Take care of the neck of the crankshaft with neat movements.

It is best to do it a small wooden wand. May come with a pencil.

Tighten the pump fastening bolts to the cylinder block.

All details set in order to remove.

Adjust the tension of the drive belt of the gas distribution mechanism. If the oil fell on the gear of the camshaft or the tensioning roller, clean the surface and degrease them White by Spirit.

Install the new oil filter and fill the new oil.

Run the engine and let it work at idle 1-2 minutes to uniform oil distribution by its details.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments