The work of the engine is carried out due to the fuel mixture, in time entering the combustion chamber. If there is extraneous noises in this process, in particular a knock, then these are signs that signal a violation of the efficiency of the motor department.

Engine valve car

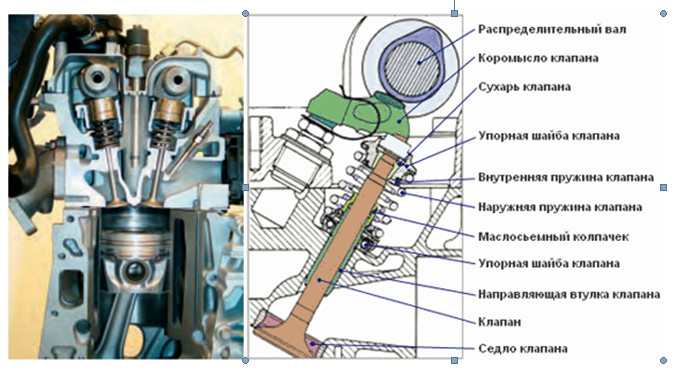

The top arrangement of the valves has the main timing systems.

In them, the main structural element is the DVS valve.

His work complements the rods, pushers and rocker.

The adjustment of the valves "is engaged" camshaft.

The principle of operation is due to the interaction of elements.

When the shaft is rotated, cams, carrying out motion, affect the pusher, observing a certain sequence.

It follows its lift, in parallel, the rod is risen.

In turn, it puts pressure on the shoulder of the rocker inside, which rotates and activates intake and outlet channels, also at a given sequence.

The head of the cylinder is their location.

Outsided noise in the engine

The perpetrators of the appearance of foreign sounds can be various problems. First of all, there is an increase in revolutions, with a weak oil pressure level.

Also on the appearance of noise affect the gaps that increasingly contribute to this.

The simplest reason is the wear or failure of the component mechanism.

Diagnostics are valve providing input and output of fuel. It will be necessary to ensure the proper level of pressure so that the operation of the mechanism is not interrupted and corresponded to the standards.

To this end, the viscosity level of the oil must satisfy weather conditions.

In winter, for example, the indicator in question must be reduced.

If the engine is not enough, then the knock is present in a consequence of significant wear of the pushers.

Such mechanisms, due to contamination, or leak, prevent the oil supply to the device, which contributes to the occurrence of sound.

In the case of a diesel engine, the recovery passes through their configuration.

Adjusting valve gaps

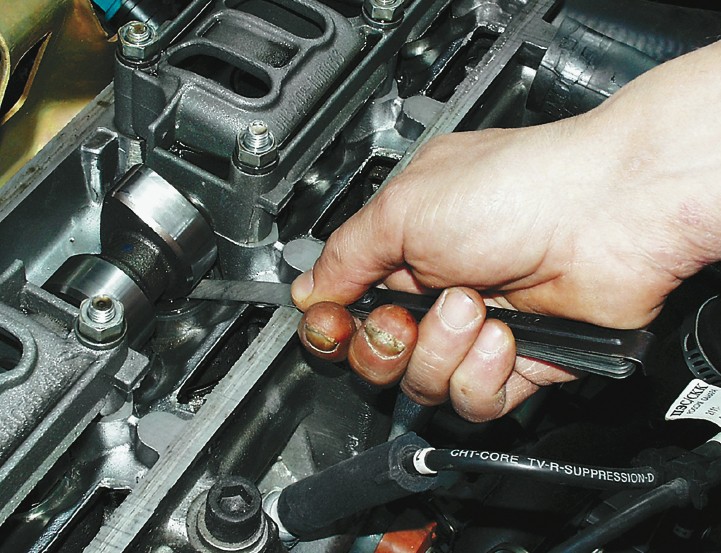

If the reason is not in the pressure of the oil, it is necessary to dismantle the lid and make sure the state of the gaps.

When increasing them, a knock appears contributing to the consecutive failure of component parts.

Here it is more expedient to be adjusted.

It is carried out by means of special probes in the form of plates.

If the camshaft is located on top, the devices are placed in a gap formed by the pusher and cam.

With its standard location, the plates are inserted into the gap between the upper edge of the rod and the rocker.

Depending on the car manufacturer and the engine compartment, the noise level is different.

There is a direct dependence of the number of valves and the strength of the knock.

The more details wearing, the more stronger.

For the means of hydraulic pushers, the clearance is normal on an ongoing basis, which contributes to the absence of noise during operation.

Maintenance GRM

To increase the stability in the operation of the MRM, the valve cleansing is necessary. After a long operating car, the valves turn the residual product layer (Nagar).

This prevents the establishment of normal performance.

Periodic cleaning is performed to eliminate this phenomenon.

Elements of the device are also checked, since the worn parts contribute to the increase in the gap, consequently, the appearance of sound support.

Curved rod or unfit spring are prerequisites for the formation of knocks.

Raising the number of revolutions, sometimes there is a slight tapping, which resembles blows about a metal object.

The reason for this phenomenon is detonation.

Its occurrence is due to a violation in the ignition settings, during the operation of a low-fuel mixture.

At the same time, a nagar appears in the combustion chamber.

For obstruction, such phenomena should more often conduct an inspection of the engine department for operation.

If the technical inspection is constantly, then the consumption of fuel decreases, and the formation of noise is not supposed.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments