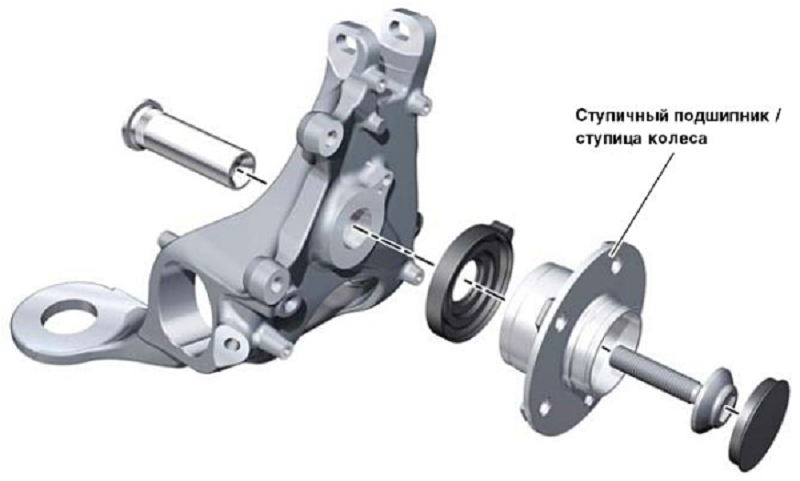

The hub is an element of the chassis of the vehicle providing the connection of the wheel with the axis. Thanks to the wheel bearings that act as an intermediate link between the axis and the hub, the wheels rotate with minimal resistance.

Content

Construction and principle of the operation of the wheel bearings

Hub bearings are one of the most high-loaded parts of the car. They have pressure of the entire mass of the vehicle, as well as multidirectional loads that occur when driving on irregularities, acceleration and braking. Therefore, these nodes put forward serious requirements, since they depends on the safety of the ride.

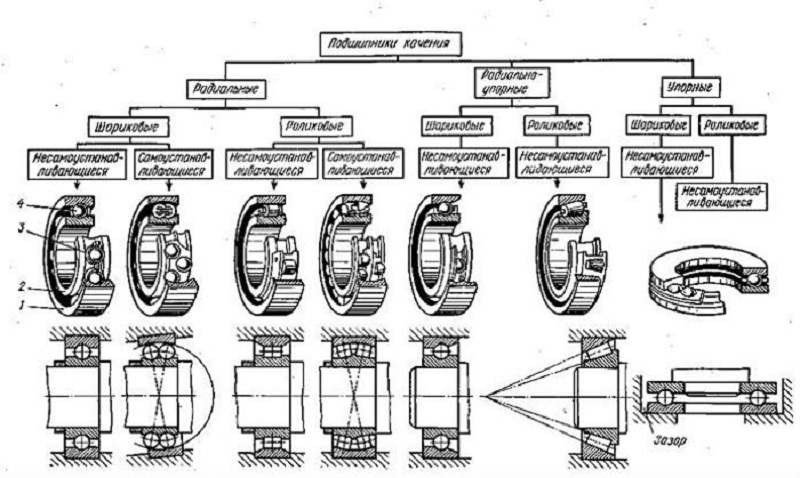

In the design of the car in the hubs apply rolling bearings. Types of bearings are different, although their design is identical. They consist of several parts:

- Separator.

- Rolling bodies.

- Outdoor and inner clip (rings).

Rings of bearings are supporting surfaces for rolling bodies, which are placed between rings. With its inner ring, the bearing sits on the axis, and the outer is mounted in the hole of the hub.

To evenly distribute rolling body around the circumference, the separator is used. Another task of the separator is to eliminate the contact of the data of the bodies. In the design of some types of hub bearings, anthers are additionally used, which prevent dirt and dust from entering the node. Such nodes are closed.

Varieties of hub bearings

Rolling bodies in the bearings of the hub are balls and rollers (conical or cylindrical). Round rows can be one or two. Radial (cylindrical roller and balls) and radially resistant (tapered roller) bearings were obtained.

As for modern models, equipped ABS, the bearing of the hub in them is an integral part of the hub itself. It is closed and maintained, and its resource is identical to the service life of the vehicle. When the node is output, it is necessary to change the hub assembly.

Radial type bearings are mounted one by one on the hub. They are maintenance-free and closed, it does not provide adjustment for them, and possible backlash are removed by landing on the axis and in the hub with a strong tension.

Radial-stubborn bearings are not rarely mounted on two on the hub. Such nodes are open and landing with small tension. This design makes it possible to perform adjustment to eliminate the backlash.

Radial-resistant bearings are used on the slave axis, and on the leading - radial shock. For example, on the VAZ 2107 ahead on the hubs are mounted on two conical bearing, and behind one ball. And on the VAZ 2108, the two-row cylindrical component is used in front, and the conical is mounted on the rear axle.

Lifetime of wheel bearings, signs of wear, diagnostics

For the service life of the bearings directly affect the features of the car operation, timely maintenance and quality of the manufacture of nodes. As a rule, the bearing resource is one hundred thousand mileage kilometers. Frequent movement in bad roads, as well as ignoring the adjustment in order to remove the backlats (in the bearings of the conical type) entail enhanced wear of rolling bonds, as well as their tracks on the climam. Ingestion of sand and dust reduce the resource of bearings.

However, it is impossible to allow critical wear of nodes, otherwise the risk of bearing destruction is appropriate, which is accompanied by jamming the wheels or its breakdown from the axis. The main sign of the wear of the hub bearings is the emergence of a distinct hum when driving from the wheel. With insignificant wear, the hum is quiet, but over time it will increase. You can use the car with such symptoms, however, it is desirable to perform the diagnostics of the wheel bearings as soon as possible and adjust or replace them.

Critical wear signal - the occurrence of the crunch. This indicates the destruction of the bearing. With these features, it is impossible to operate the vehicle, and the damaged node must be replaced.

The diagnostics of the bearings of the hub - the event is not difficult, each can perform it. It is necessary to hang the wheel and twist it to determine if there is no subdings and jams. Then raise the wheel, keeping it down and at the top. The play on radial cylindrical products is not allowed, but it may be present at the radial-resistant bearings, but is insignificant.

Plate in cylindrical products indicates a strong wear and a need to replace, as they are unregulated. But the backlash in the bearings of the conical type can be eliminated.

Adjustment work

To conduct adjustment work, screwdrivers, hammer, passage and standard set of keys will be required. Adjustment on all cars is actually identical and differs only in some details.

- On the hub that you need to adjust, loosen the wheel bolts.

- With the jack, post and remove the wheel.

- Taking advantage of the hammer and screwdriver, run the protective cap, mounted in the center of the hub.

- Using the passage, bent the stopper mustache and pull it out.

- Tighten the hub nut until you stop, then unscrew back to ¼ turn.

- Check the ease of rotation of the hub. It should easily spin without jail.

- Collect everything back and check back the backlash.

If, by means of adjustment, it was not possible to eliminate the backlash or when rotated, you notice the crunch and subflinking, it is necessary to replace the bearing.

Tips Profi, Nuances when replacing the hub bearing

The replacement technology of the hub bearing is not complicated, however, it requires a special equipment - press or powerful plumbing vice. A method with a hub clogging with a hammer with a mentor is not suitable for working with hubs, since there is a high risk of a node skew or damage to the seat of the hub bearing.

When installing the new bearing, pay attention to the ease of its landing. The bearing must be very tight in the hub, and a small resistance testifies to the wear of the landing place. In this case, the hub is subject to replacement. During the landing of the new bearing, pay attention to its centering, otherwise, when installing, there is a risk that it will go to the skew and hurt the surface of the landing place. More about replacing the hub bearing you can learn from this video.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments