Fuel pressure is an important parameter that needs to be constantly controlled. Its value directly affects the efficiency of the motor, its power and behavior in various modes. Consequently, every car owner who does not indifferently does the technical condition of its own car must periodically check the pressure. How to do it, read further in the article.

Content

- Fuel Rampa VAZ 2110 Device and Purpose

- How to check the pressure in the fuel ramp, methods of checking

- How to check the pressure in the fuel ramp using a air pressure gauge for measuring tire pressure

- What pressure in the fuel ramp VAZ 2110 is considered the norm

- Safety and fire safety rules for work

- Tools, fixtures, consumables

- How to check the fuel pressure VAZ 2110 engine 1.6 without reverse, checkout (step by step)

- Tips Prof.

Fuel Rampa VAZ 2110 Device and Purpose

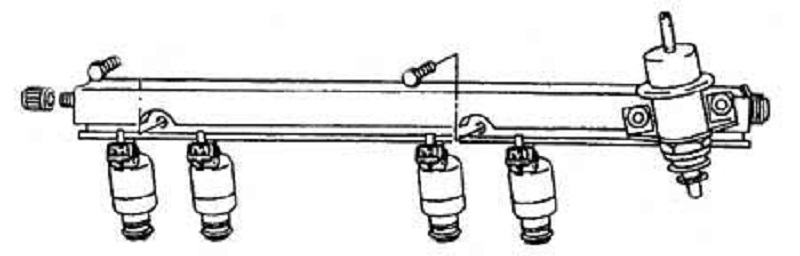

The fuel ramp (rake) is a mandatory element of the Fuel system of the DVS with a distributed injection. It is a segment of a hollow tube, the ends that are closed on both sides and are distinguished by the presence of taps for connecting a smaller diameter tubes. Through the data of the tube fuel flows to the injectors, which are located on it. In addition, there is a pressure regulator on it. The fuel that falls inside the ramp moves by means of nozzles into the inlet tube. In addition to the discharge tubes, there is also a locking fitting and a hole in this design.

How to check the pressure in the fuel ramp, methods of checking

You can measure this parameter by several methods. One of the most common is the acquisition of a special set, which includes a special adapter for connecting, a pressure gauge (it is due to the measurement of it) and drain. For the purchase of these devices, it is necessary to allocate about 1500 rubles. But you can do differently - go to a hundred, where experts for 300-500 rubles. Required measurements.

However, there is a more sophisticated method that does not require additional costs - it is possible to measure fuel pressure using an ordinary pressure gauge used to test the pressure in the tires. At the same time, it is advisable to use a pressure gauge for measurements, the limit of which is minimal (approximately 6-7 atmospheres). This will minimize the error.

How to check the pressure in the fuel ramp using a air pressure gauge for measuring tire pressure

Sequencing:

- We prepare the pressure gauge and wind the fum-tape right under the nozzle.

- We prepare the oxygen tube with a diameter of 9 millimeters and put it on top.

- With the help of a clamp from two sides, fix fasteners.

- To avoid fire, cover the generator with something.

- Next, it is necessary to reduce the pressure in the system to a minimum. Make it easy. We remove the fuse that feeds the fuel pump (on the VAZ 2110 it is located near the control unit, under the cladding, is the extreme on the left side), we start the motor and wait until it stalls.

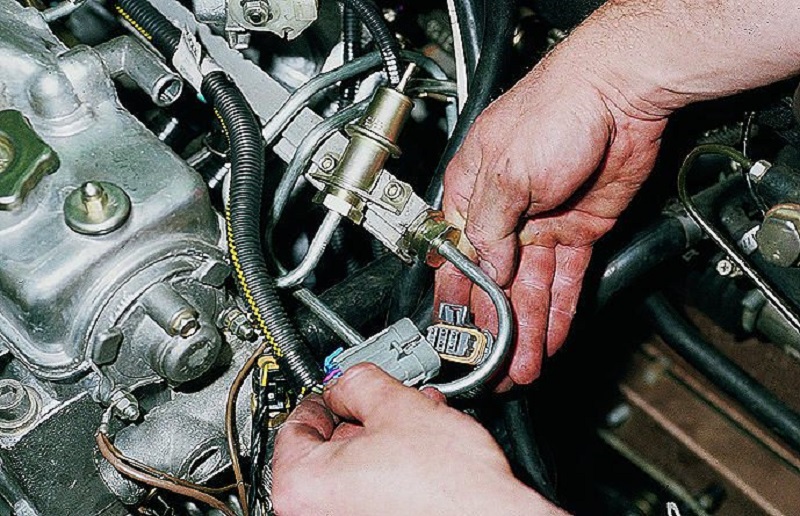

- Twisting plastic cap, which is installed on the fuel ramp.

- Look inside the cap - there will be a nipple and a standard hole. Take the cap from the wheel and unscrew it. Be prepared for a non-essential fuel release, which is due to the presence of residual pressure.

- Then we put on the output of the ramp the second edge of the hose and fix the clamp.

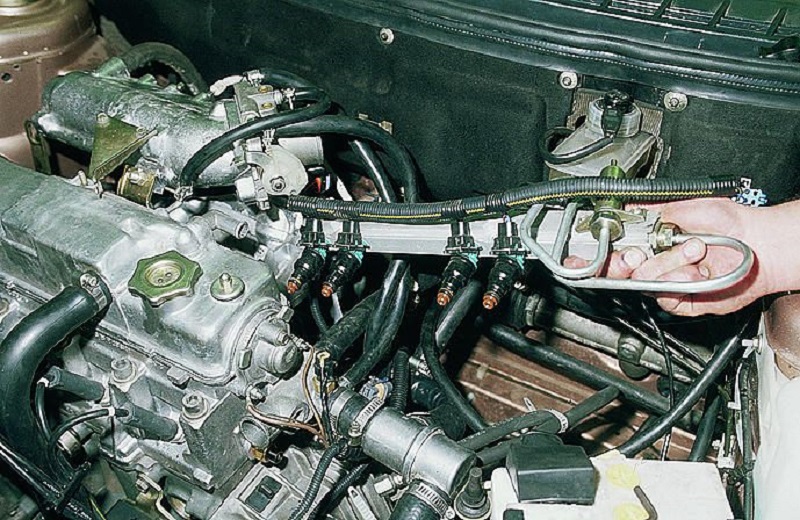

- We remove from the "Protection" from the generator and start the motor. However, do not forget to return the fuse in place.

This method of fuel testing is one of the simplest, accurate and very effective. By the way, if there are no clamps, special bushings of the bolts for adjustment can be used for tightening. At the same time, for the purpose of fixing on the fitting it is necessary to wear a small rubber ring.

What pressure in the fuel ramp VAZ 2110 is considered the norm

Normal fuel pressure must be 2.8-3.2 bar (atmospheres). If you remove the vacuum tube from the pressure regulator, the indicators may insignificantly grow (0.2-0.7 atmospheres).

Safety and fire safety rules for work

Be very careful when working. To avoid ignition, be sure to cover with something generator.

Tools, fixtures, consumables

- Hose.

- Manometer.

- Stub.

How to check the fuel pressure VAZ 2110 engine 1.6 without reverse, checkout (step by step)

On the VAZ 2110 volume 1.6, the pressure indicators in the fuel ramp are unchanged and vary within 3.6-4 bars. Measurements are often performed according to the same principles as described above. However, there are several other non-standard techniques.

Method 1:

- We prepare the above-described design - the hose on the end with a pressure gauge.

- The diameter of the hose should be approximately 8 millimeters.

- Measurements are made at the output from the fuel pump module.

- A pressure equal to 5-7 atmospheres is considered to be a normal parameter.

Method 2:

- Recall how the return on the engines with the drain ramp closes. It is better to join at the same time right on the fuel pump.

- Double hose should be dismantled and insert a plug (instead of the plug, you can apply a "nipple" from the fuel filter).

- Tension single pipe to the pump fitting. Measurements are made directly at the ramp.

Tips Prof.

It is important to remember that problems with the fuel system are usually manifested by sharp "dips" during the achievement of high rotor of the engine. In addition, when driving a car can pull, it is tupit when setting speed and so on. In this case, it is necessary to check the pressure. Only after that you can detect the main reasons for problems - gas station, nozzles, filters and so on.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments