Brake pads are among the most important parts of the vehicle. They are all the time to be increased friction, and even more than brake discs, as not made of metal, but from wear-resistant composite materials. Therefore, their wear and subsequent replacement are logical and inevitable.

Content

- Brake pads when changing and why

- Brake shoe wear

- Original brake pads, brake pads analog - which choose

- Brake pads to pay attention to when buying

- Choosing a place for repair and tools assistants

- How to remove the brake pads, the course of work is styled

- How to replace brake pads, step-by-step instructions

- Tips of professionals

Brake pads when changing and why

There is no unambiguous opinion, which brake pads are subjected to wear more - rear or front. Someone believes that the rear, because all the dirt and dust, which the front wheels discard, falls on them. Others think that the front, which is fairly fair. The peculiarity of the structure of the brake system is that the front pads are grabbed first after pressing the necessary pedal. Thus, it is they who experience the bulk load, as a result of which the fuel surfaces are more intense. Third believe that the rear and front pads need to be changed at the same time, so that the brake discs of all four wheels evenly grabbed.

It is necessary to replace the brake pads if the brake pads are rather worn. Some car manufacturers equip brake pads with special sensors. Such mechanical devices produce control over the wear of the pads and publish a characteristic creak when the critical value is reached. As for electronic devices, they are sent to the vehicle control signal to wear the brake pads into the vehicle control unit, including on the control panel indicator.

In addition, wear pads can be determined by transverse special furrows, which are located on protective linings. When erasing the lining to the base of such strips, it is time to change brake pads. The minimum allowable thickness of the brake pads is two or three millimeters. More accurately find out this parameter can be judging by the technical description of the vehicle and the technical characteristics of the brake pads themselves.

Brake shoe wear

The velocity of the brake pad depends on the set of factors:

- Significantly affects the velocity of the pads the design of the brake mechanism, the weight of the vehicle, the material from which the brake pads themselves are made, as well as brake discs and drums.

- Much depends on the style of driving a car - drivers who prefer aggressive ride style with emergency stops and sharp accelerations, brake pads wear out much faster than motorists who perform all maneuvers gently and smoothly.

As for the signs of wear of the brake pads, there are several of them. On the wear of the brake pads you will be prompted by the car itself.

In this matter, the main thing - in a timely manner and correctly recognize the signals that will serve the vehicle.

- If the braking path of the car is increased or it leaves from the straight trajectory of movement, this indicates problems in the brake system.

- The increase in the working stroke of the brake pedal or mitigating the brake pedal together with a decrease in the degree of brake fluid, will indicate the need to check the braking mechanisms.

- If the brakes are triggered too dramatically when the wheel is hopped. Most likely, the friction pad, which consists of a resin, synthetic rubber and a variety of modifiers, was fully worn and braking occurs as a result of friction of the metal department of the block of the brake disc or drum.

- Because of the wear of the brake pads, the wheels are felt with a sharp braking. In this case, it is impossible to let the problem on samonek and ignore the anomalous embossed and the noise that makes the brake mechanism, since the movement with such brakes can end with the jamming of the pad with its destruction or blocking the wheel, as a result of which the brakes will simply refuse.

- If the flare has changed its shade on the coating of wheel drives, it will also report to the problems of the brake system. It should be coal and dark. If it is metal splashes, which give themselves with glitter, the friction pad is worn, as a result of which the brake disc began to scratch the block.

Original brake pads, brake pads analog - which choose

Undoubtedly, when choosing brake pads, the original parts are certainly better. However, their analogues are no less qualitative, as manufactured using original spare parts technologies. It's no secret that the original is more expensive than a duplicate.

Yes, and it is much more difficult to purchase it, as the majority of these element production companies sends almost ninety percent of the original brake pads to the conveyor. Their analogues can permanently cost two, and even three times less, although the quality does not suffer. They may differ insignificant changes in the material of the pad or other nuances that do not go beyond the scope of that.

In addition, when choosing brake pads, many drivers think that sports pads are more efficient. However, it is not. Only not in urban conditions.

Brake pads to pay attention to when buying

Choosing brake pads for your car, you need to pay attention to how they look outwardly. Quality goods must be well packaged, without various damage. On the block should be a special sign that they are certified.

They also should not have different cracks, defects, the material should not be peeling, and the metal base should not be fed. Look, that would be on the structure of the lining there were no foreign bodies. If the price of the brake pad is low, then cheap materials used in the manufacture. In addition, pay attention to the brand name - any defects in the inscription indicate a fake.

To date, there are many options for protecting the goods from the fake. For example, special signs on the package or on the shoe itself.

Choosing a place for repair and tools assistants

Such work is desirable to conduct on the lift or observation pit, which will provide you with convenient access to all necessary mechanisms. In addition, you will need such a toolkit for work:

- Jack.

- Balloon key.

- Hammer.

- Caucasics.

- Passatia.

- Screwdriver.

How to remove the brake pads, the course of work is styled

- Using the automotive jack and any additional backups, it is necessary to make the wheel hanging, thoring the pre-fastening bolts. Thug bolts in suspended state almost impossible, and the vehicle can fall from the jack and damage the wing, wheeled arch or threshold.

- Then remove the wheel from the hub. It is not necessary to clean it far, you can use it as an additional backup.

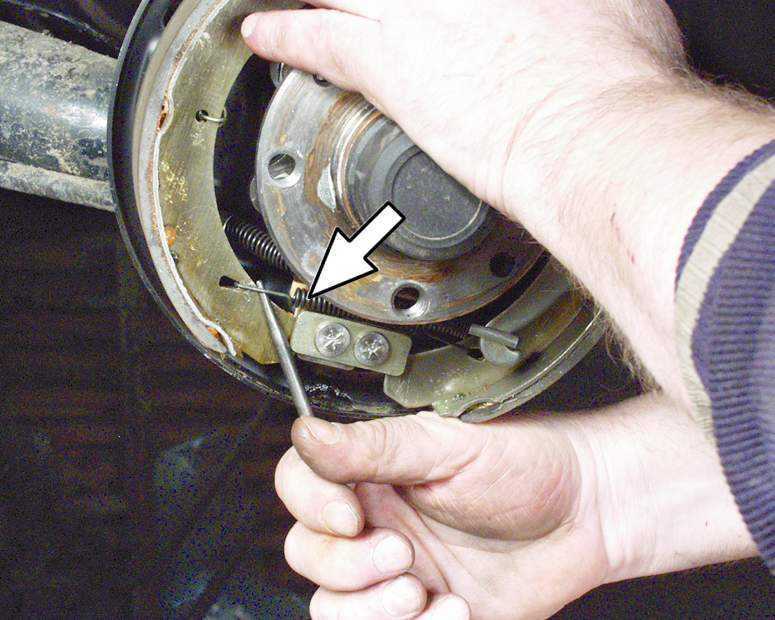

- With the help of a screwdriver on both sides we breed the pads until the brake piston arrives at the initial position.

- We unscrew the brake caliper fastening bolt to the guide bushings. If the bolt does not want to succumb, do not need to apply additional efforts to break it, use any lubricant or aerosol and after a few minutes the bolt will unscrew without problems.

- There are two bolts in the brake caliper that fasten it with a bracket. Find the bolt, which, when unscrewed, will allow you to lean the bracket and the body to the side, while not the brake hose.

- Unscrew this bolt.

- Now remove the brake pads and determine the degree from wear.

How to replace brake pads, step-by-step instructions

Installing new brake pads is performed in the reverse order, without losing a single moment. It is important to establish tin damper pads to the original position. In addition, be sure to tighten the wheel fastening bolts.

Tips of professionals

Experienced motorists are advised to carry out "hot braking" after replacing the brake pads, which will allow you to check the operation of the pads on the subject of the screen or other noise, drive out the air from the system and evaluate the quality of work.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments