All modern cars are equipped with such a desired element as a camshaft sensor. His main task is to feed the fuel injection into cylinders. When the sensor is faulty, it is necessary to determine the cause of its failure and replace it. About this further in the article.

Content

- What is DPRV, assigning camshaft sensor

- Where is the camshaft sensor

- Principle of operation of the DPRV.

- Factors affecting the performance of the camshaft sensor

- Signs of DPRV faults

- Causes of the camshaft sensor fault

- Checking the camshaft sensor

- When you need to change the camshaft sensor

- Replacing the camshaft sensor

- Tips Prof.

What is DPRV, assigning camshaft sensor

The camshaft sensor is a device that ensures the normal functioning of the power unit. DPRV determines the angular position of the gas distribution mechanism according to the position of the crankshaft. Then information from the sensor goes into the engine control system to control the ignition and injection.

Where is the camshaft sensor

Located DPRV from the side of the hydraulic pulleys and pumps. The axis of the sensor always corresponds to the direction of the axis of the camshaft.

Principle of operation of the DPRV.

The principle of the DPRV operation is based on the Hall effect, which is why experts call it a hall sensor or phase sensor. In the sensor itself there is a magnet that creates a special magnetic field. The pin (reper or metal teeth), located on the specifier disk, closes the magnetic gap, as a result of which certain changes occur in the magnetic field.

The motor control unit, receiving a signal from the sensor, receives information about the position of the piston of the 1st cylinder. The control system is then the ignition of the fuel mixture and fuel injection in accordance with the order of the operation of the power unit cylinders. If DPRV fell out of order, it should be replaced as soon as possible for the normal functioning of the vehicle and reduce the fuel consumption.

Factors affecting the performance of the camshaft sensor

The performance of the phase sensor directly depends on the temperature mode. Overheating can bring it out of order. The DPRV will also not function due to the failure of the wires by which it receives and transmits the signal, breakage of the reference. An important role is played by pollution or damage to the sensor itself. In addition, under the difficult operating conditions (cargo transportation, road driving), the sensor can be shifted or a short circuit may occur. It is very important to systematically perform diagnostics of the sensor and change it every 4-5 years, in order to avoid unexpected breakage at the wrong time.

Signs of DPRV faults

The main features of the fault of the camshaft sensor include:

- The engine does not start.

- High fuel consumption.

- Detonation in the engine at dynamic loads.

- The heated force aggregate is unstable functioning at idle.

- The number of revolutions independently decreases or increases.

- Detergence of dynamics when driving.

- SIGNAL OF SIGNAL "CHECK ENGINE".

Causes of the camshaft sensor fault

The main reasons for the release of DPRV in order:

- Motor overheating.

- Short circuit inside the sensor.

- Offset DPRV installation.

- Disk breakdown with referees.

Checking the camshaft sensor

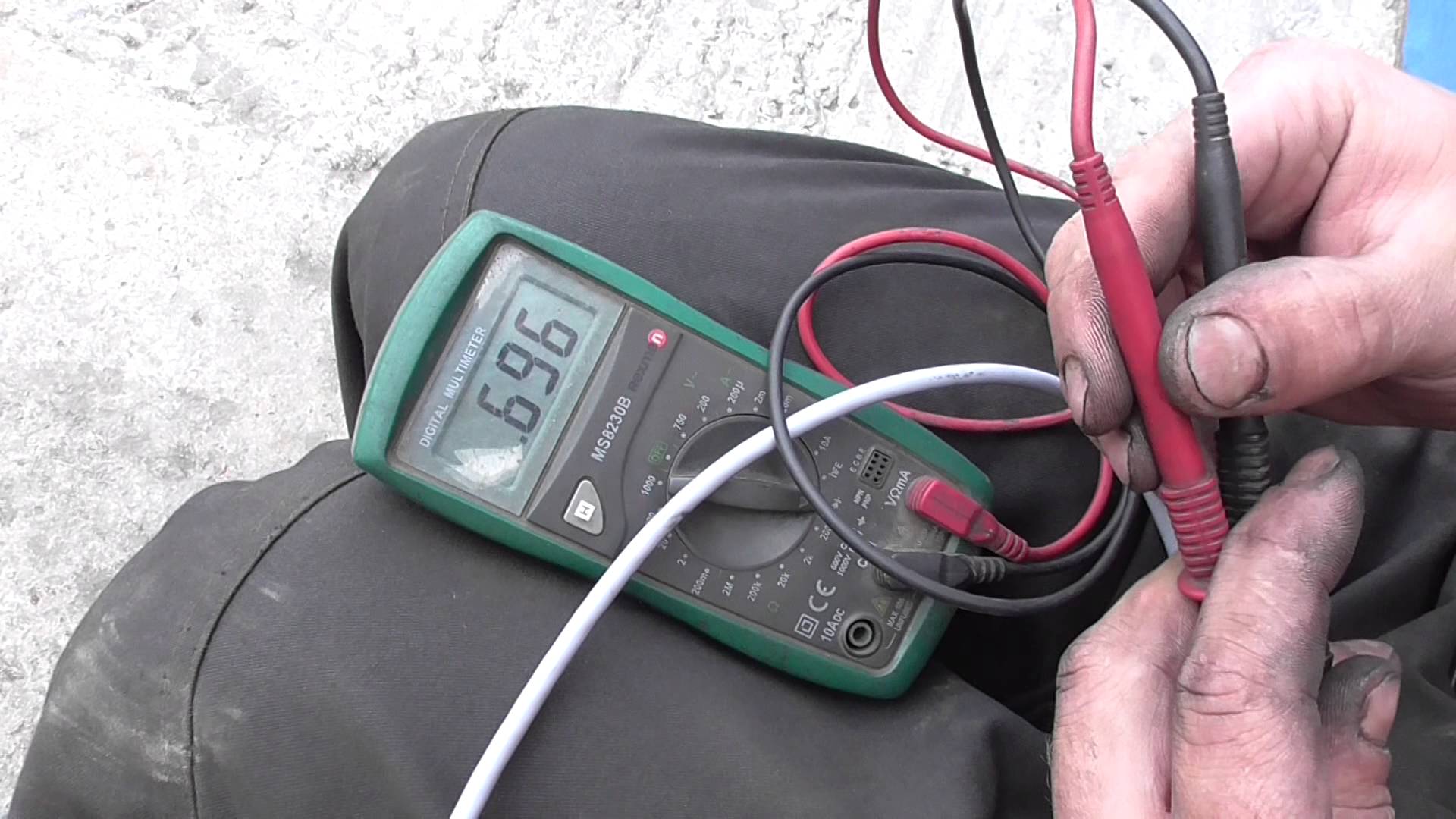

Before checking the DPRV tester, visually inspect the gear rotor and the sensor body for the presence of metal chips or damage. It can also cause his breakdown. Before starting the check, be sure to disconnect the ignition. Then begin to disconnect the wires from the device.

Tools for diagnostics

To verify DPRV, it will be necessary:

- Multimeter / tester.

- Screwdriver.

- Pliers.

Multimeter / Tester will help to carry out a detailed sensor check. It will show what is the fault: in the wiring or sensor itself.

Diagnostic scheme

Before checking the sensor, it is necessary to study the connector on which: minus and positive contacts, as well as contact for signal transmission.

- Turn on the ignition and check the DPRV multimeter. The mass of the tester is connected to the mass of the motor. It is important that the measurement corresponds to the voltage value at the terminals of the battery. If the values \u200b\u200bdo not coincide, then the sensor power supply circuit failed.

- Then the same way measure the voltage on the mass of the sensor. It must be zero.

- Connect the minus and positive DPRV wire. Middle contact connect through the tester. Thus, one multimeter wire is connected to the signal output of the sensor, and the second is powered by the control system input.

- Then turn the engine starter. If the DPRV operates normally, it will show the voltage of 0.4-5 volts. If the values \u200b\u200bare different, replace the sensor.

If the check showed that the sensor was out of order, it is not necessary to pull it with its replacement. Although the motor will work without it, it will work in emergency mode, and the fuel consumption will rise at times, since fuel in this case will be supplied simultaneously to all cylinders.

When you need to change the camshaft sensor

DPRV must be changed every one hundred thousand km. Run even if the sensor still works. This is due to the fact that it does not tolerate overheating, and it has to work constantly with a variable temperature mode. When buying a new sensor, pay attention to the recommendations of the professionals and use the parameters specified by the manufacturer.

Replacing the camshaft sensor

Replacing the DPRV - the occupation is simple. We give an example of replacing the sensor on the VAZ family cars. From the tools you will need only the key to "10".

Replacement of DPRV on engines of the 21124 and 2112 engines

On these engine, the sensor is on the end, inside the rear lid of the drive belt of the gas distribution mechanism. To replace the camshaft sensor on VAZ 2110 and 2112 cars, you just need to unscrew two bolts with a key to "10" and remove it from the lid.

Replacement of DPRV on engines of the 21114 and 2111 series

On the engines of this series, the phase sensor is inside the camshaft cover, behind. The VAZ 2115 replacing the camshaft sensor is performed in the following order:

- Turn off the ignition and disconnect the wire block, squeezing the plastic retainer on its housing.

- The key to "10" will unscrew the bolt.

- Remove the sensor.

Tips Prof.

If after replacing the sensor you do not reset the errors in the computer, the motor will start functioning in normal mode only after the second launch. As for the CHECK fault signal, it will disappear by itself.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments