The vehicle speed is a key parameter that needs to be constantly monitored. Exceeding the permissible speed is not only fraught with obtaining a fine, but may entail serious consequences. About this further in the article.

Content

- Speed \u200b\u200bsensor, device and principle

- Where is the speed sensor on the VAZ 2115

- Malfunctions Speed \u200b\u200bSensor VAZ 2115

- Signs of malfunction at the VAZ Speed \u200b\u200bSensor 2115

- Causes of the failure of the VAZ Speed \u200b\u200bSensor 2115

- Diagnostics of speed sensor

- Tools, fixtures, consumables

- Choosing a workplace

- How to remove the speed sensor VAZ 2115 (step by step)

- How to put a new VAZ 2115 speed sensor (step by step)

- Tips Prof.

Speed \u200b\u200bsensor, device and principle

The purpose of the high-speed controller in carburetor and injection motors is to transfer information about the speed of the car on the instrument panel. The principle of operation of DS is quite simple and based on the effect of the hall:

- The controller transmits voltage signals to the ECU with a frequency, directly proportional to the velocity of the wheels of the vehicle.

- The computer, in accordance with the signals taken from DS, performs the operation of the engine at idle and using the XX sensor controls the air flow into the throttle bypass.

- It is very important that the frequency of the controller pulses was directly proportional to the actual speed of movement.

Where is the speed sensor on the VAZ 2115

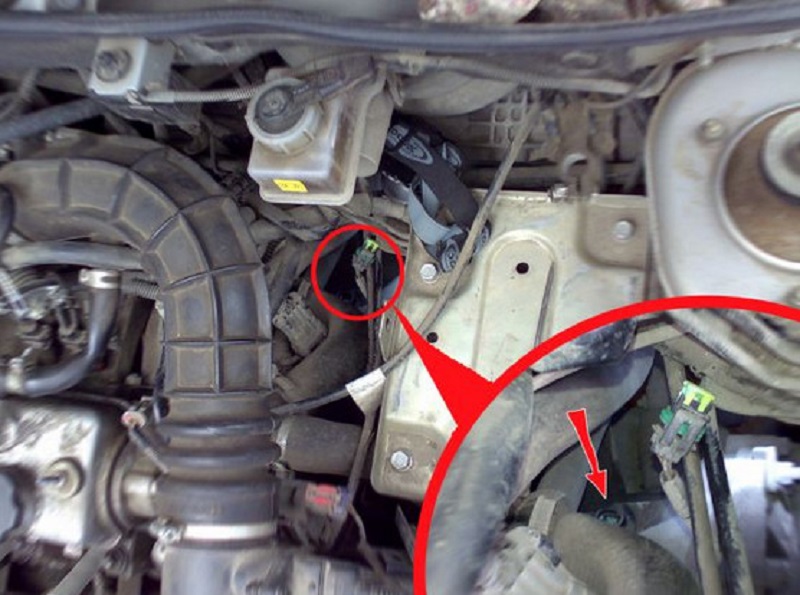

DS is located at the top of the PPC housing (see photo). But access to this controller is not so easy. To get to the device, you need to drive the car to the overpass or pit, and climb under the vehicle.

Malfunctions Speed \u200b\u200bSensor VAZ 2115

If the P0500 error appears during the diagnostics, it means that the speed sensor does not receive a signal. If you see the code P0503, then the incoming signal is interrupted for certain reasons.

Signs of malfunction at the VAZ Speed \u200b\u200bSensor 2115

- One of the most likely breakdown symptoms is incorrect values \u200b\u200bon the speedometer, in particular, the arrival of the dial is chaotic moving on various sides.

- Another sign - the engine runs on xx with interruptions.

- Floate speed on XX.

- Increase fuel consumption.

- Dips for overclocking, i.e. when the driver presses gas, the engine does not respond to it, the power set does not occur.

Causes of the failure of the VAZ Speed \u200b\u200bSensor 2115

- Open in the electrical circuit of the regulator.

- The device is not in contact with the on-board network.

- The mechanical drive of the device is faulty.

- Due to damage or wear, a sensitive controller element broke.

Diagnostics of speed sensor

The diagnosis of the sensor performance is performed by two methods.

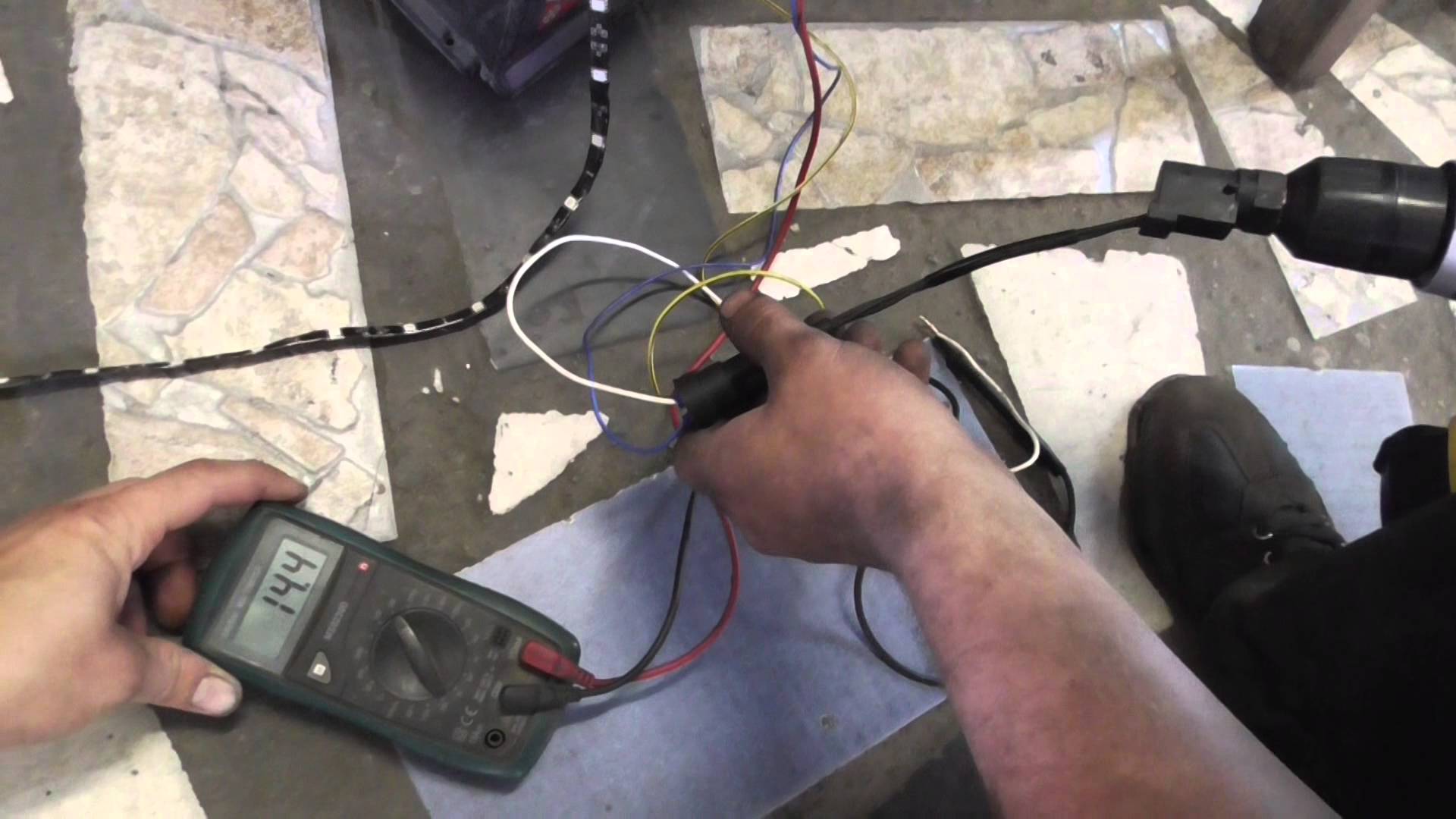

To implement the first method, you will need a multimeter:

- First of all, dismantle the controller itself. Read the removal instructions below.

- Next, set the Tester to the variable voltage measurement mode.

- The tops of the multimeter must be closed on the controller plug contacts. The first probe is connected to the contact to the dashboard, it is located in the center, and the other to the car body, i.e. to the mass.

- Front controller is a special rod. When it rotates the device starts. To diagnose the operation of the regulator, you must scroll, for which a metal tube is installed on it.

- The rod starts rotating, and information about alternating voltage will be displayed on the multimeter display, more precisely, its jumps. At the same time, the higher the speed of rotation of the rod, the largest jumps of the values. This will indicate the fault of the controller.

The second method of checking the device is performed without disassembling, but for this it is necessary to drive cars to a pit or a flight:

- When the car is on the pit, raise the left front wheel to the jack.

- Next, find the controller and disconnect the connected wiring from it.

- Now take a multimeter. Its probes must be combined with the masses and the contact of the pulse transfer to the computer, on the block it is the central and most extreme contact.

- Then rotate the wheel raised by the jack, and diagnose the values \u200b\u200bthat show the multimeter for the presence of voltage jumps. In the absence of a tester, you can apply a conventional test lamp with wire connected to it. Connect the first wire to the power, that is, to the left contact, and the other to the central one. If the lighting source is blinking when the wheel is rotated, it means DS is working.

It is possible that the reason for the breakdown of the DS lies in a bad contact with the electric network of the car, in this case it is necessary to simply replace or clean the contacts. Before diagnosing, inspect the device. If there are traces of damage on it, it may not even make sense to check it.

Tools, fixtures, consumables

- Wrench on "21".

- Screwdriver.

- Rag.

- New speed sensor.

Choosing a workplace

Works on the replacement of the speed sensor are performed on the overpass or observation pit.

How to remove the speed sensor VAZ 2115 (step by step)

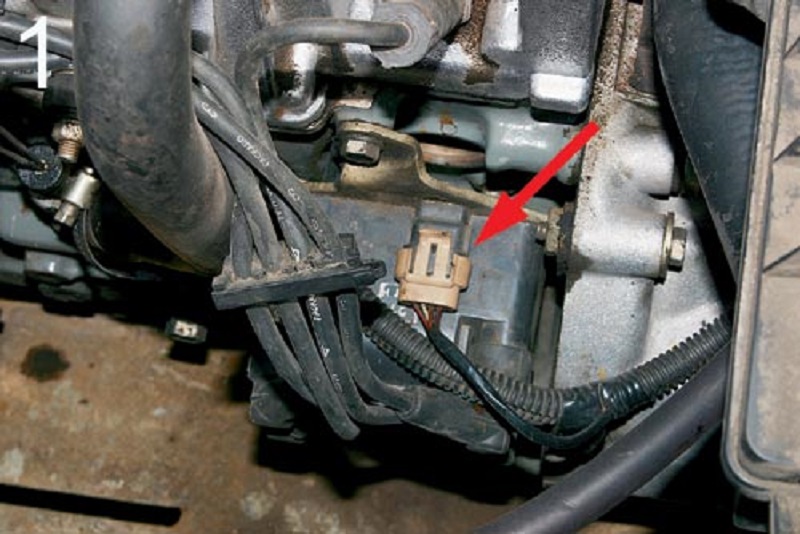

- First, turn off the ignition and open the hood.

- To facilitate the removal procedure, dismantle the adsorber. To do this, simply unscrew the nuts that lock this node, then remove it to the side.

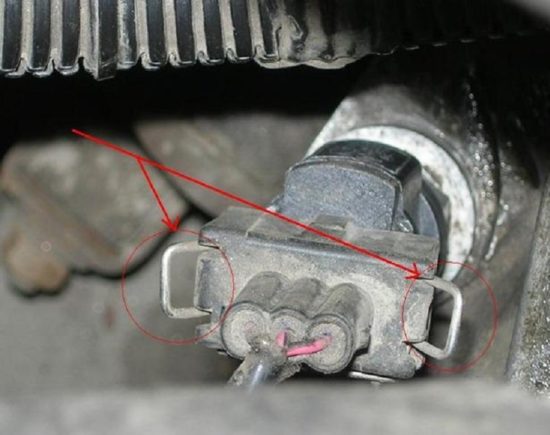

- Next, hold down the mount and dismantle the wiring connector.

- After performing these actions, proceed to dismantling the device. The device turns against a clockwise until the speed sensor is turned off completely. Using a wrench to "21", remove the sensor from the landing space.

How to put a new VAZ 2115 speed sensor (step by step)

- Clean the location of the sensor from dirt and dust.

- Then perform the installation of a new sensor. In this case, you should act carefully, since the controller housing is made of plastic, so that even insignificant mechanical effects are able to bring it out of order.

- Next, build the sensor in the seat in such a way that its grooves coincide with the sleeves, otherwise you will not be able to fix the device reliably.

- Tighten the sensor clockwise. No need to delay the device.

Tips Prof.

Detailed DC Replacement Instructions You can see in the next video.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments