The clutch in the car is the link between the DVS and Transmission. This element takes on most of the loads that occur during the transmission of torque from the motor to the checkpoint. The grip is often wearing and affect its wear is impossible, except if you switch speeds without his participation, which will certainly be lost without a trace for other parts of the engine. If the clutch fails, it is not necessary to access specialists, it can be replaced by itself, having a minimum set of tools. About this further in the article.

Content

Signs of clutch disk malfunction

Symptoms indicating the need for clutch replacement:

- Reducing the power of the motor (the clutch "leads").

- Unauthorized clutch shutdown.

- The clutch is not fully ("dropping").

- The presence of vibration when pressed pedals.

- The presence of extraneous sounds, click, jerks when the clutch is turned on.

The reasons for which the clutch disk comes into disrepair

The clutch is a very sensitive node, which causes the following reasons to breakage:

- Natural aging (i.e. wear) clutch elements. For this reason, the slave disk is often broken. Its resource is approximately 100 thousand km. Lovers of fast ride, the slave disk flashes several times faster.

- Errors in the operation of the car (a frequent problem of newcomers), when the driver goes with a squeezed pedal, keeps his foot on the clutch pedal, starts to move on large speeds and so on. Clutch with such a driving long does not withstand.

- Oil fell on friction linings. Often this happens when the seals are out of order.

- Low quality elements. In order to avoid this, buy only original spare parts.

Clutch disc fault diagnostics

| Causes of breakdown | Methods of elimination |

| The clutch does not fully turn on (ranks). When the motorist presses sharply on the gas pedal, the motor is gaining momentum, but the machine does not actually accelerate, which is especially noticeable while driving on the rise; Fuel consumption increases; may smell overheat friction overlays | |

| The clutch drive is seized or damaged | Singing must be eliminated. If necessary, replace the drive |

| Ferricular lining of the slave disk are very worn or burn | Should replace the slave disk |

| Ground Pressure Disk, Flywheel, Friction Slave Disc Linked | Surveated surfaces need to be thoroughly rinsed with gasoline or White spirit and wipe them dry. If the slave disk is very grilled, replace it. Do not forget to eliminate the cause of grinding |

| The clutch does not completely turn off (leads). The front transmission switches with difficulty, the reverse turns on with noise. Gearbox proper | |

| The petals of the diaphragm spring are worn at the point of contact with the extrusion bearing | Replacing the clutch basket |

| Balance or Pump Dissament | Replace clutch basket |

| On the Slots of the Primary Shaft PPC, the hub of the slave disk | It is necessary to clean the slot from the dirt, and small damage is eliminated by supfil. With substantial damage or wear of the slots, you need to replace the primary disk and / or CAT disc |

| Working surfaces of the pressure disk or flywheel strongly and unevenly worn out | Replacing the flywheel. If the surface of the pressure disk is damaged, replace the clutch basket |

| Weakened rivets either broke the friction linings, fed by the slave disk | Replace the disc |

| Cable clutch drive cable | You need to lubricate the cable with a motor oil. But if it did not help (the cable shell is damaged, its wires are spinned) - replace the cable |

| Incorrect adjustment of the clutch drive | You must adjust the drive and replace the deformed clutch plug |

| Rods when touching | |

| Zamased Friction Pads Slave Disc | Surveated surfaces need to be thoroughly rinsed with gasoline or White spirit and wipe them dry. If the slave disk is very grilled, replace it. Do not forget to eliminate the cause of grinding |

| Zadira on the working surfaces of the pressure disk or flywheel | Replace flywheel or clutch basket |

| The springs of the sprinkler of the springs were broken, the windows under the springs were worn out | Need to replace the slave disk |

| Lost elasticity Spring plate disc drive | Need to replace the slave disk |

| Cracks or strong wear of the closed disk friction linings, loosening the lining | Need to replace the slave disk |

| The slave disk deforming | Need to replace the slave disk |

| On the Slots of the Primary Shaft PPC, the hub of the slave disk | It is necessary to clean the slot from the dirt, and the small damage to eliminate the proper. With substantial damage or wear of the slots, you need to replace the primary disk and / or CAT disc |

| Hences clutch drive cable | You need to lubricate the cable with a motor oil. And if it did not help (the cable shell is damaged, its wires are grown) - replace the cable |

| Knock, noise or rattling when the clutch is turned on | |

| The springs of the sprinkler of the springs were broken, the windows under the springs were worn out | Need to replace the slave disk |

| The slave disk deforming | Need to replace the slave disk |

| Cracks or strong wear of the closed disk friction linings, loosening the lining | Need to replace the slave disk |

| Increased noise while turning off the clutch | |

| Clutch shutdown bearing was worn out or damaged | Need to replace the bearing |

Choosing a workplace

To replace the clutch without removing the PPC, the presence of a lift or observation pit.

Tools, fixtures, consumables

When performing work, the tools will be required:

- Jack.

- Rozhkin and end keys on "19" and "17".

- Pipe Amplifier / Mounting.

How to replace the clutch disc 2110 with your own hands without removing the gearbox (step by step)

Order of work:

- On the left wheel loosen the fastening bolts, lift the front of the wheel on the jack and put on the "goats".

- Remove the wheel and unscrew the two fastening bolts of the lower ball support.

- Remove the minus terminal from the battery.

- Remove the DMRV, loosen the clamp, fastening the DMRV corrugation, and get the air filter.

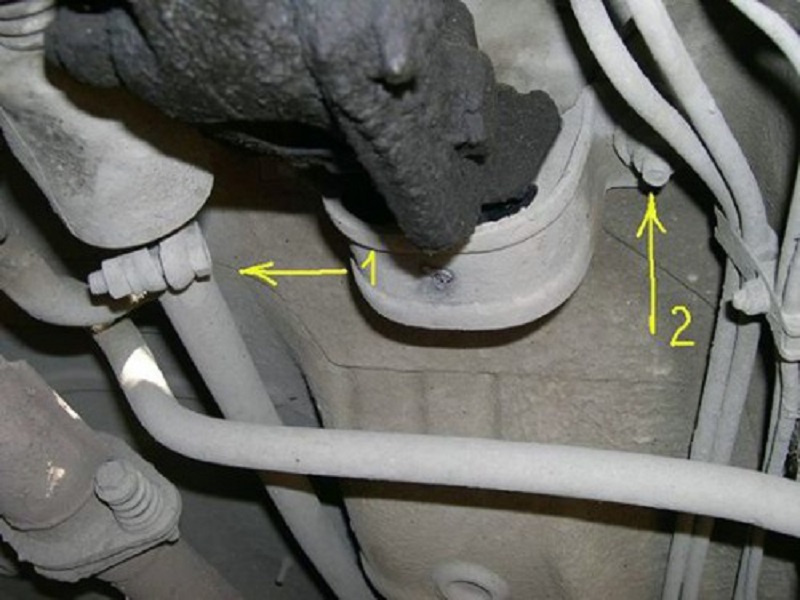

- Remove the clutch cable from the plug. Loosen the two nuts fastening the rope to the bracket on the KP.

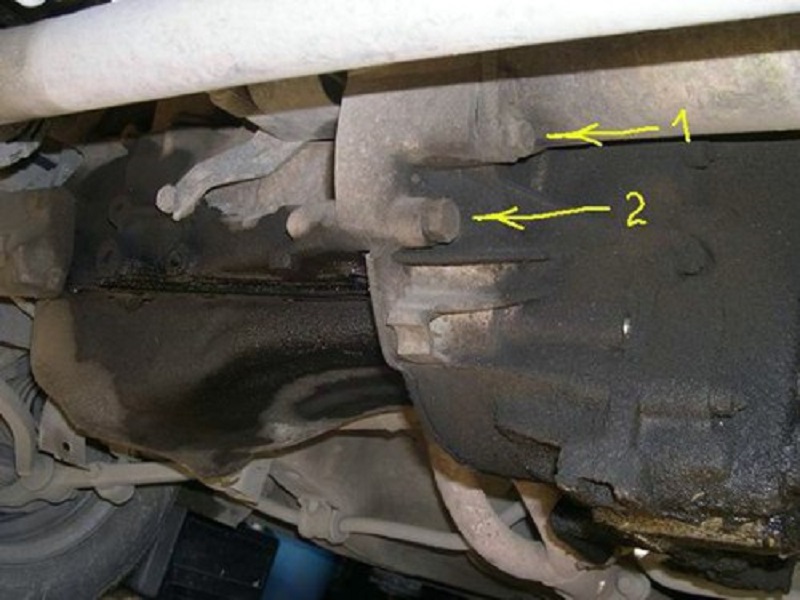

- Remove the bolt fixing the starter to the checkpoint. Next, remove the first KPP fastening bolt.

- On the PPC we find the second fastening bolt and let it go.

- Then release the upper bolt fixing the starter.

- From the speed sensor dismantle the connector.

- Then unscrew the speedometer cable.

- Remove the lever and longitudinal stretch.

- Unscrew the bottom bolt fixing the starter.

- Remove the third bolt fastening gearbox. Next, unscrew another nut next to the right shrus.

- Remove the two fastening bolts of reactive traction.

- Weaken the nut on the KPP control drive clamp and remove the craving from the box.

- Install the support for the engine and unscrew the two nuts securing the rear pillow.

- Gently remove the gearbox from the power unit and release it to the ground so that it hangs on the semi-axes.

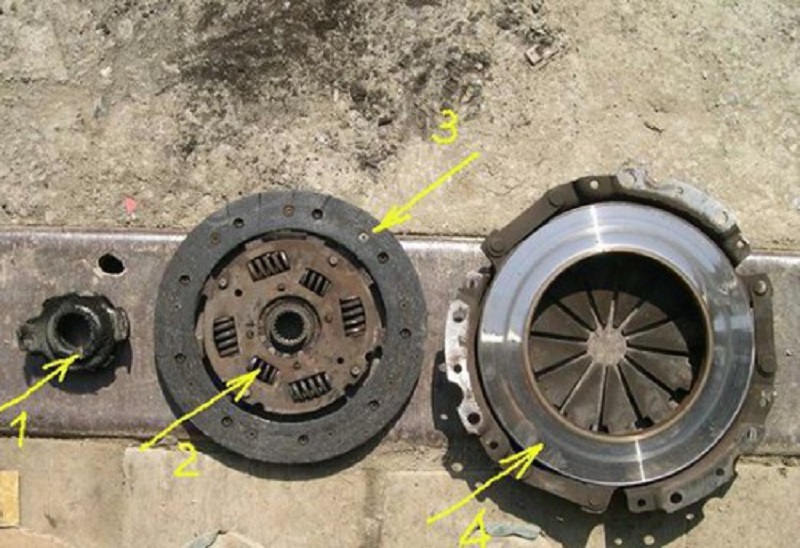

- You can immediately replace the clutch shutdown bearing.

- Rate wear, replace the disk, if necessary, install a new basket, check the petals.

- Assembly perform in the reverse order.

Tips Prof.

We advise you to see the following video:

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments