The purpose of the clutch system in a car - gently, without sharp jerks to remove the load from the engine, while ensuring a smooth start of the vehicle. This allows you to significantly reduce the wear of parts and extend their life. There are no specific deadlines to replace this unit, since it all depends on the working conditions of the car and the driving manners of the owner. It is recommended to conduct clutch diagnostics every 80,000-100,000 km.

Content

Coupling VAZ, device and principle

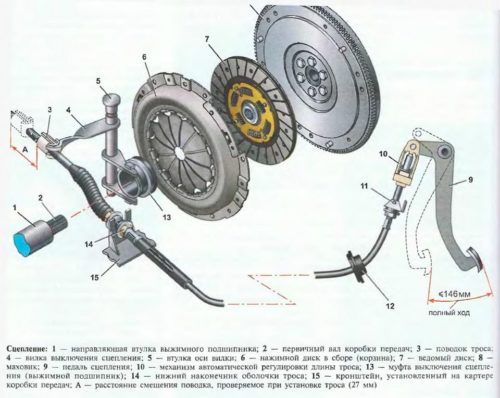

On VAZ 2107 cars, a dry one-piece one is installed. The grip is constantly closed. The unit connects the engine crankshaft and the primary car gear shaft. With it, it takes a rupture of torque that comes from the engine to the checkpoint. Thanks to its design, the clutch provides smooth inclusion of transmissions by slipping work disks.

On the VAZ 2107 the clutch is installed on the flywheel. The adhesion itself is closed with a special protective aluminum crankcase. Carter is attached at four points bolts to the cylinder block. On the primary shaft of the gearbox, the hub is free on the slots. A slave disk is attached to the hub, which has special slots that divide it into 12 smooth parts. From both sides to the slave disk the friction linings are attached.

From the disk to the hub, the force transmits the absorber of the twist oscillations, or damper. The clutch basket is attached to the flywheel in six points with bolts. The basket itself consists of a casing, a disk and a pressure diaphragm spring. Purpose Dick is attached to the casing freely. The slave clutch disc, under pressure from the diaphragm spring, is tightly fixed between the flywheel and the pressure disk.

The inclusion / off of the adhesion on the car brand VAZ 2107 is carried out from the salon suspended pedal with hydraulic drive. The pedal is on the same axis with the brake pedal, which is attached to the partition of the separating interior from the engine. A special spring is attached to the upper part of the pedal, which makes it easier to turn off the clutch. In addition, the pusher is attached to the pedal on the hinge. The pedal move is rigidly limited - on the one hand, an adjusting screw, on the other, the move of the piston itself in the clutch drive cylinder.

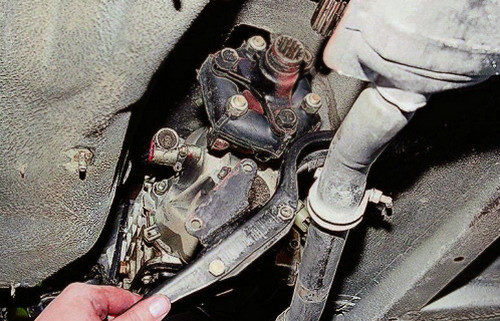

The main clutch cylinder is fixed with two nuts to the node of the pedal of the car (located in the engine compartment). The cylinder is connected by a hose with a tank hydraulics. The tank itself is on the partition between the cabin and the engine compartment, on the left side. Bachts are made from a special translucent plastic, which allows you to control the level of fluid in the system. The tank cover is equipped with a dense corrugated liquid sedator.

In the main clutch cylinder, the liquid is supplied through a pipeline fitting, which brings it to the working cylinder. The second end of the pipeline is connected to the lug of the fluid drive hose. The tip is attached to the body bracket.

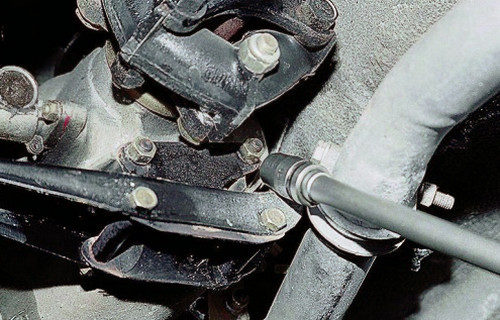

The working cylinder is attached at two points to the bolts to the clutch. The role of the pusher of the clutch fork performs the cylinder rod. The plug is attached on the ball support, which is placed in the clutch crankcase. One of her end rests on the pusher nut, the other, with a figured spring, gripped tightly to the clutch bearing clutch, which is attached to the sleeve of the PPC cap.

When the engine works, both parts of the clutch work as one. Torque comes from the crankshaft to the primary shaft of the checkpoint. When the clutch pedal is pressed, the force using the hydraulic drive is transmitted to the plug, which turns on the ball support. The plug moves the release bearing over the sleeve. In turn, the bearing presses on the spring of the clutch basket. The spring, located on the supporting rings, is compressed and removes the pressure disk away from the slave. Thus, the Primary PPC shaft is disconnected from the crankshaft, and the torque feed is interrupted. After the clutch pedal returns to its original position, all parts with a spring are returned to the original, and the torque is restored.

Causes of Clutch Losses

The most common causes of the failure of the clutch:

• Development and grinding, as well as damage and production of friction linings.

• Lack of gaps, as well as too large gaps in the clutch shutdown system.

• Air in hydraulics.

• leak in the hydraulic engine and the main cylinder.

• Damage and deformation of discs.

• Weak rivets.

• Slots are seized in the hub of the slave disk, as well as the clutch drive mechanism due to wear.

• Bearing Development.

• Fabulous springs of oscillation damper.

• Faulty fork or spring fork.

• Worn sealing rings, and, as a result, impaired tightness.

To eliminate all the above troubles, you can replace individual parts, but it will be more reliable to change the entire system.

Signs of clutch breakage

The moment when the grip needs to be repaired, it is quite simple to determine the following signs:

• Foreign noise, clicks, grinds when switching speeds.

• The clutch "drops, especially this is noticeable when the load.

• Not completely disabled, "leads."

• Coupling rattles.

• The car twitches at the start.

What should be paid to clarify the diagnosis of clutch breakage

When setting the speed or braking of the car to switch the gear in the gearbox, the crankshaft is constantly disconnected and connected to the power transmission. This operation is performed very often and intensively, so that, over time, the signs of clutch malfunction are becoming increasingly explicit. All clutch malfunctions are divided into two common types: incomplete clutch inclusion (leads) and incomplete clutch shutdown (dropping).

Any experienced car owner knows how to check the clutch on a complete shutdown. To do this, the engine is triggered on small revolutions, the clutch pedal is completely squeezed and include the first transmission. If it turned on easily, then the clutch completely turned off the drive - everything is in order.

When in motion you hear the smell of Gary, the auto loses the speed on the cool lift, and in general, it is badly accelerated - the "slip" of the clutch is obvious. That is, the clutch to the end does not turn off - both disks are not tightly tight.

Very simple and at the same time very reliable way to independently diagnose clutch problems:

To begin with, the engine warms so that the cold thick oil does not create additional resistance. Next, the car put on the "handbrake". It is necessary to do it on a flat surface, without steep slopes. After that, the engine accelerates to 1500-1700 revolutions, squeeze the clutch pedal, include the first transmission, then smoothly release the pedal.

As a result, the engine must stall. The engine is not stalled, or the engine stalls after a while - the clutch definitely requires repair or replacement.

Replacing the clutch disk VAZ 2107

First you need to make the right choice of workplace. It may be an overpass, lift or observation pit. If there is no ability to use these jobs, the car can be raised on the jack, so that access to the coupling is available. It should not be forgotten about the safety technique - the wheels must be reliably fix and put the car onto the handbrake, so that the machine does not ride during operation.

tools, fixtures, consumables

Before starting repair work, it is necessary to prepare the following tools and materials:

• Set of keys.

• Screwdrivers - flat and curly.

• Pliers.

• Clean vehicles.

• Jack.

• Remkomplekt or new clutch assembly.

When buying a new Remkomplekt, you should not save - buy original spare parts, better in the set.

sequence of repair work, advice pro

It should be noted that under the replacement of the clutch means worn and failed a clutch basket, a disk, as well as the release bearing. At the same time, or in a separate case, the main and working cylinder may fail, or the clutch hose. After replacing the clutch or its individual details, the clutch is required.

If there is a replacement of a basket or a clutch disk, you will have to partially dismantle the transmission. The box remains in its place, it is just shifted a little to the side. In some cases (for convenience, inspection and replacement of the clutch crankcase, the seal of the primary shaft, etc.) the box will still have to be removed completely.

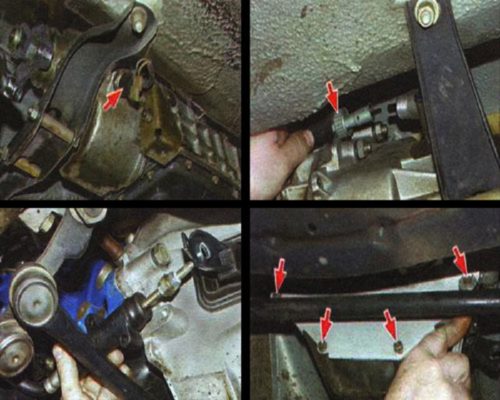

In order to remove a faulty clutch, you must perform the following preparatory work:

• Remove the starter.

• Disconnect the switching lever from the gearbox.

• Disconnect the drive shaft.

• Disconnect the working cylinder of the clutch, as well as the flexible Speedometer shaft from the gearbox.

• Remove terminals or chips from the sensor, which includes lighting when the reverse transmission is turned on.

• Disconnect the exhaust system from the gearbox.

• Unscrew the bolts with which the gearbox is attached to the engine.

• Disconnect the rear pillow (traverse), through which the PPC is attached to the body.

After conducting the above manipulations, the gearbox is neatly discharged to the distance, sufficient to the primary shaft that the primary shaft is disconnected from the basket, and carefully be carefully opened it on the receiving pipe of the car exhaust.

To remove the gearbox completely, before unscrewing the bolts with which the gearbox is attached to the engine, disconnect from the engine's exhaust manifold the receiving pipe (pants).

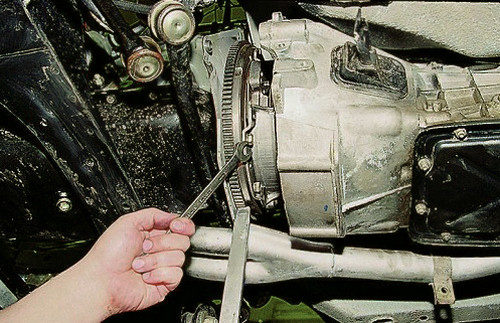

After accessing the VAZ 2107 clutch basket opens, it can be replaced or repaired. To do this, we unscrew the bolts with which the basket is attached to the flywheel and dismantle the clutch.

In the process of performing work, we definitely pay attention to the following points:

• When dismantling the starter, it is not necessary to disconnect the wire from it, you only need to remove the terminals from the battery.

• Before disconnecting the cardan, it put labels on the position of the hinge plug relative to the gear flange of the main car transfer gear.

• Removing the flexible drive of the speedometer, it can not be bent too much.

• If the basket after repair is to be installed back, before it dismantled with paint, chalk, chub or kerner, the position of the unit relative to the flywheel is scheduled. It is necessary to set the basket at the same position.

• In order for the clutch cover when dismantling not deformed, fastening bots must be unscrewed evenly, 1-2 turns.

• If the clutch basket is attached when unscrewing the bolts, the flywheel begins to scroll, it is possible to use a mount as a lever for fixing.

• When assembling the clutch is very important without errors to install the disk. A large drive of the disk must be addressed to the basket.

As it is clear from the foregoing, the replacement of the clutch "seven" - the task is not too complicated and quite feasible. You can more clearly familiarize yourself with the process of replacing the clutch of the VAZ seventh model from the video:

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments