Vehicle motor is a fairly complex and technological unit, which consists of a large number of nodes that perform their narrow functions, which ultimately transform the energy of the combustion process of fuel into energy mechanical, which is capable of driving a vehicle. In other words, that would be filled into the tank fuel turned into motion, you need to use many nodes and aggregates, which every car enthusiast should know.

The GBC is called the head of the cylinder block, which is essential from vehicle nodes, which is responsible for controlling the combustion procedure of fuel in the motor and the output of exhaust gases. It is possible to highlight the main parts and mechanisms of the GBC:

- Block head or crankcase body, in which there are cooling system channels, all mechanisms, combustion chamber and oil pipeline.

- Holes with planting plane or thread for installing nozzles or spark plugs.

- The combustion chamber where the working mixture is flammable.

- Block head gasket.

- Drive gas distribution mechanism.

- Gas distribution mechanism.

- Threaded mounting and planting planes for graduation and intake manifold.

Content

Tools assistants

Replacing the cylinder block is a rather responsible and laborious process, it is carried out to replace the gasket or to install new valves and sleeves. However, it is not necessary to contact the auto repair shop at all, you can replace the cylinder head yourself, having minimal locksmith skills and tools:

- Mandrel for pressing bushings.

- Mandrel for pressing oil recovery caps.

- Micrometer for the valve valves and guide bushings.

- Mandrel for crimping bushings.

- Scan for 8.03 millimeters, to deploy new bushings.

In addition, it is desirable to have an electric tile, which is endowed with a closed heating element. Before pressing the sleeves here you can heat the heads.

Also do not forget about the device to fix the valves when paving the springs. For this, a small board with bottles or something like that is suitable for this.

CHBC, work on dismantling GBC, step-by-step instruction

As a rule, the replacement of the cylinder block is not carried out. The process begins with replacing asbestometallic or thin metal gasket.

When the leaks of the coolant or motor lubrication are detected, it does not have to think long. It lies the reason just in this gasket, which you need to replace. However, at first it is necessary to get to it.

- From the battery, disconnect the mass.

- Correctly install the first cylinder piston - to the position of the first time.

- We merge the coolant.

- If the vehicle is still hot, in the power system it is necessary to reduce the pressure.

- Disconnect the fuel tube from the collector.

- Remove the cylinder head cover.

- Then we find and disconnect the wires from the full air flow regulator.

- Next, we relax to the throttle node clamp of the airconducting fitter.

- Remove the element with the air filter housing.

- Do not forget to replace the air intake hose.

- We find and turn off the screw, which fixes the pipe holder of the water pump pipe.

- We assign to the bracket and weaken the clamp.

- From the throttle unit, disconnect from the throttle assembly and liner hoses of the cooling system.

- Now weaken the clamp, which fixes the brake hose to the fittings.

- We divide all the wires from the position of the valve flap, idle and oil level controls.

- We find and disconnect from the ignition candles the ends of high-voltage wires.

- From the receiver pull the harness of the wires.

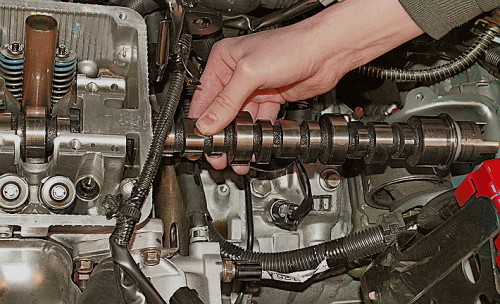

- Remove the camshaft drive belt, after removing its cover. It is very important in this case not to rotate both shaft before mounting the drive belt.

- Disconnect the plastic holder connecting the component of the oil and fuel frame.

- Soak and remove the cd fastening bolts. Do not forget that the cylinder head fastening bolts are turned only on the engine, which did not work for several hours and completely cooled.

- Remove the head. This element is quite heavy and it is desirable to remove it with an assistant.

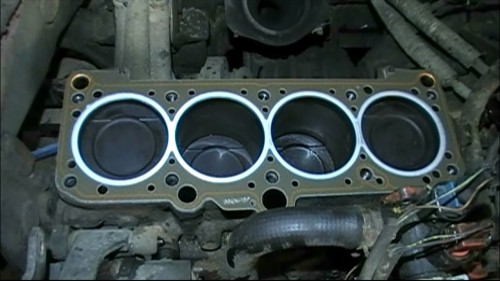

- Now we clean the flushing surfaces of the GBC, they must be clean and dry.

- From threaded connections, we remove the oil, since otherwise cracks may appear in the GBC, which will negatively affect the operation of the vehicle.

Gasket GBC, types of pads, which choose

The GBC laying is necessary to strengthen the connection site of the cover and the head of the cylinder block. The gasket of the GBC should be changed with each replacement of the head of the cylinder block. It is important to understand that the gasket of the GBC and the usual laying of the lid of any element are different things.

It is responsible for such motor systems - gas distribution, lubrication and cooling system, therefore, the requirements for it are appropriate. In no case cannot save when replacing this gasket. If the symptoms of its wear are noticeable, the gasket should be replaced immediately.

There are several types of pads:

- Beszasbestos - high reproducibility and low collapse.

- Asbestos - elastic, plastic and heat-resistant.

- Metal - the highest quality, however, along with it, and the most expensive.

So, to replace the gasket gasket is necessary in the following cases:

- With signs of leaks of oil.

- If you have noticed a foreign mixture of a muddy white when checking the cavity of the oil - getting a coolant as a result of a worn gasket.

- If you notice the white smoke that comes out of the exhaust pipe.

Installation of gasket GBC

Installation of gasket GBC - the process is very simple. You just need to install a new head laying on the block on the installation bushings, but do not forget to align it on the guides. GBC collect in reverse order.

GBC, installation of cylinder

Naturally, the GBC installation is carried out in reverse sequence to the removal. Special attention should be paid to fastening bolts. The tightening of these bolts must be carried out only with a torque wrench.

Tips of professionals

If there are small experience and knowledge, these work can be carried out on their own. However, it is necessary to understand the process itself and possess knowledge about the design of the GBC.

All units and vehicle components need constant maintenance, diagnosis and repair. Cylinder heads are no exception. Elements that are loaded mostly require increased attention to themselves. These are elements of the gas distribution mechanism - camshaft seals, valve glands, cylinder head gasket and others. On the proper work of the GBC and premature wear of parts, the mass of factors has its influence, the main of which relate to diagnosis and maintenance.

Tightening the nuts without observing the points of the effort controlled by a torque wrench, disrupt the order of nuts fastening or tightening bolts cannot be, as it can lead to the curvature of the head housing, which is able to remove the motor.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments