The car suspension is designed primarily for damping vibrations and oscillations that occur during the movement of the car. The suspension consists of a number of elements, each of which performs its function. So, the suspension levers are designed to create a dynamic body connection and wheels, which ensures the free movement of two elements relative to each other.

Shock absorbers and springs are quenched by most of the vibrations and oscillations, and the transverse stability stabilizer prevents cross-sowing of the car body.

The suspension design contains another item - a set of silent blocks. Details are small, but very important. Below we will consider in detail their purpose, and also tell me how to replace the silent blocks with their own hands.

Content

- Silent blocks, appointment and installation site

- Polyurethane silent blocks, what is the advantage

- Signs of Silent Blok faults

- How to check silent blocks on VAZ 2110

- Tools, fixtures, consumables, Tips Profi

- Puller for Silent Blok - Principle of operation and device

- Replacing the front-top lever silent blocks

- Axial backlash what it is and how to eliminate

- Replacement of the silent block of the front bottom lever

Silent blocks, appointment and installation site

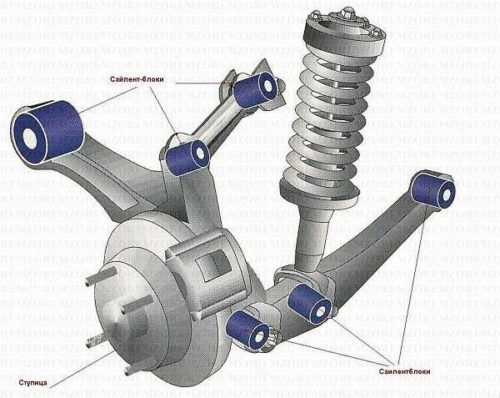

In the front suspension of the car, silent blocks are installed in the levers. With the help of silent blocks, the levers are connected to the wheel hub and car body. Such a connection is mobile and elastic. Sometimes silent blocks are installed on places compound a transverse stability stabilizer with a lever - if it provides the suspension design. Also, the silent block can be installed on a depreciation rack - into the lower part, where the rack is connected to the hub.

If we talk about the rear suspension, then there, silent blocks are installed on transverse and longitudinal levers, in the locations of the torsion beam and body, as well as on shock absorbers. In general, the number of silent blocks depends on the design of the car suspension.

On VAZ 2110, silent blocks are located in the following places:

• Cross levers (fastening sites to the body).

• Embers of the transverse stability stabilizer (mounting place to the front lever).

• The lower part of the amortized rack is the place of attachment to the transverse lever).

• Stretching the transverse lever (at both ends - the location of the connection with the crossbar and lever).

Total in the front suspension VAZ2110 is 5 silent blocks. In the back of the car there is a torsion beam, so there is Silent blocks only 4. Two of them play the role of fasteners of the beams to the body, two more are in the lower parts of the shock absorbers. Another place where silent blocks can be installed - steering. In some models, the hinge is used as an element of an elastic mobile connection of the steering mechanism and the thrust. The average service life of the rubberometallic hinge is about 100,000 km of run. Of course, this is not an accurate indicator, it depends on the working conditions of the car, the quality of the road surface and the quality of the part itself. Since domestic roads are far from being better, you can usually withstand silent blocks not more than 50,000 - 60,000 km. After that, they should be replaced.

Polyurethane silent blocks, what is the advantage

For the service life of the hinge still affects a number of circumstances. For example, the rubber used in the design of the silent block is very badly affected by oil refining and chemistry products, which is treated in winter. The temperature differences also have an extremely negative impact on the part - in summer, the rubber softens, and in winter it begins to freeze and becomes too hard. In the conditions of hard mechanical loads, the rubber begins to braid, "age", lose elasticity, smear, and fails.

Much better in equal terms showed themselves silent blocks with elastic elements made of polyurethane.

Polyurethane hinges have much better performance than rubber tabs. They are less destroyed under the influence of chemicals, retain elasticity regardless of the ambient temperature, oil products are practically not available on polyurethane. Of course, the polyurethane silent block will work much longer than rubber. However, like any item, over time, it requires a replacement, because it starts to grow old and decrease.

Signs of Silent Blok faults

The most important sign that the silent block is fully developed and must be replaced, is a noticeable reduction in car manageability, a rather strong vibration in the steering wheel appears, the obvious sounds of the "iron" blows when driving on irregularities and uhabam.

How to check silent blocks on VAZ 2110

It is possible to determine that the silent block requires replacement, it is possible to visually, weave the car on the pit, the overpass or lift. If there are cracks, scratches, dents, other damage during the inspection on the parts, it must be replaced as soon as possible. Another simple method for checking the state of silent blocks is to use the usual mount.

For this, the tool with effort is swing the suspension elements in which silent blocks are installed. If the mount at the same time goes freely, or in the process you can hear shots, knocks, crossed - the hinge is subject to replacement. It should be noted that silent blocks do not change one by one, but only pairs, even if the second element on the suspension does not have signs of faults.

Tools, fixtures, consumables, Tips Profi

The work on the replacement of silent blocks is simple, but special tools may be needed for reassessing hinges.

Total to work will be needed:

- actually, new silent blocks

- caid, horn keys of the desired size (head and rattling head)

- puller for silent block

- lubrication (soap solution)

- jack

- vice

- hammer, slight chisel.

The hinge sits in his place very tight, and for its dismantling, most likely, you will need a special puller. The necessary condition for high-quality replacement of hinges is their correct selection. Before you go to the store, you need to know which silent blocks on the Va2110 are installed most often, their serial number, size parameters, etc. Repeat, the hinge sits very tightly, and the inconsistency of the size of only a few millimeters will lead to the fact that the new silent block simply will not be pressed.

Special puller applies to work, with which it is easy to extract the old part and presses the new one. Sometimes it happens that to replace silent block you have to remove the suspension element, for example, lever. In this case, the puller is successfully replaced by conventional plumbing visits. True, in this case, the silent block will be quite difficult to extract. Then it can simply burn the soldering lamp or on the open fire. Sometimes folk craftsmen copble with a sledgehammer and metal breakdown.

Before installing a new item in place, it must be mounted with soap or soap solution. It will greatly facilitate the installation. It is impossible to use lubricants from oil refining products - solidol, cast, oil, etc., as they negatively affect the rubber. This does not concern polyurethane hinges, for which petroleum products practically do not affect. To make it easier to facilitate the installation, a small chamfer can be removed on the rubber surface of the part. The main thing is not to rearrange and do not cut too much.

Puller for Silent Blok - Principle of operation and device

Such a device can be bought in the auto parts store or do it yourself. The simplest puller consists of a nut, a long bolt, several segments of pipes of different diameters and several thick washers.

The principle of his work is extremely simple: to push the old silent block, take the bolt to which the washer dresses. Its diameter should be slightly smaller than rubber hinge insert. Bolt passes through a hole in the hinge. On the other hand, the pipe trim, the diameter of which should be equal to the diameter of the lever, that is, the pipe resumes the lever. After that, the bolt is dressed another washer, the dimer of which should be greater than the diameter of the pipe segment. Now you can wind the bolt nut.

Next, the device works like this: the nut when sheeps rests into the washer and begins to gradually pull the silent block. Truck trim, in turn, allows the hinge to gradually leave the nest, without resting at the same time in the other washer.

Pressing is made in the same way, only at the same time use the pipe cutting optionally, since the new silent block will rest on the puck when he will sit in place. You can pinch the hinge and ordinary vice, however, at the same time, he does not sit in full, as it will be thrown into the sponge of the vice, and it will have to annoy it.

Replacing the front-top lever silent blocks

Procedure Next:

The front wheels are lifted using the jack and fixed. The front wheel is removed. The upper lever is dismantled. Before dismantling it is necessary to check if the silent blocks do not slide inside the lever, they must sit there tightly.

So that the top lever is spelled freely, you need to dismantle the upper support. It is quite difficult to make it, because to unscrew the nuts very hard. To do this, turn the wheel and slightly hit the hammer on the couch. After that, the support should jump without problems. We unscrew the top bolt lever. It is long, so the operation will take some time. After the bolt is extracted, you can remove the lever and proceed to replacing the silent block.

Important moment: the problem may not be in the silent block, but in the lever. In order to check the self-functioning of the lever, you need to install a bolt in place, and see whether you will tell you lower than the axial backlash below). If there is anything, the replacement of the hinge will not give anything, you will have to repair or change the lever.

Old silent blocks can be removed by the puller, but in most cases it is not needed - the displaced item is removed by the hammer and chisel. Moreover, on domestic cars, they fall out from the first second strike. The main thing - without fanaticism, so that nothing to break. After the old silent block is extracted, a new one is installed in its place. This is where the puller is useful - the entire installation process is described above - with the help of the same puller or vice.

Video to replace front top silent block:

Axial backlash what it is and how to eliminate

This is a rather frequent "disease" of the lower lever of domestic cars, and the VAZ 2110 is no exception. The play occurs when the bracket on the body, to which the lever joins, for some reason, the gap appeared between the lever and the sleeve, because of which the silent block starts moving inside the lever.

Axial backlash very negatively affects the work of the front suspension, so it is, of course, should not. If there is a backlash, it can be fixed in several ways. First, you can try a little squeeze the bracket on the body. It will be very difficult to do it, because one hundred hammer hit the body is undesirable, and in order to apply the passatology or clamp, it will take a fair physical force, and it will be uncomfortable under the car.

It is much easier to fix the axial backlash, placing several piles between the bracket and silent block. Although the rules need to replace the entire bottom lever along with the silent block.

Replacement of the silent block of the front bottom lever

To replace the silent block of the lower lever, you must first remove the lever itself. For this, first of all unscrew the nuts of the stretch marks, the racks of the ball support and the stabilizer. From the ball support, the lever must be removed using the puller.

Lastly turns off the lever fastening nut to the body, the bolt is pulled out, after which the lever can be removed. After that, it should be removed stretching. Since it is already disconnected from the lever, it remains only to unscrew the nut, which it is attached to the cross. Lastly, the stabilizer is dismantled. It is attached to the levers through the racks on both sides, so it can be either unscrewed on the other side and start shooting, or unscrew the mounting nut to the rack, and lever and stretch the stretching later.

By reloading the stabilizer from the levers, it remains to still unscrew the nuts of the fastening of the body brackets and remove the stabilizer along with the sleeves. After the desired suspension elements are dismantled, you can proceed to the replacement of silent blocks according to the scheme, which was described above.

Video to replace the front bottom lever silent block on the VAZ 2110 using the puller:

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments