In the process of operation of the vehicle, scheduled checks of brake hoses should be systematically carried out. If during the inspection you found mechanical damage on hoses, for example, cracking or tributes, as a result of which the quality of braking is reduced or a brake fluid leak occurs, it should be replaced as quickly as possible.

Content

Materials and tools assistants

First of all, it is necessary to think about the tools that will be needed in the process of this work:

- Rozhkovo-attacked keys at 15, 14, 8.

- Item key on 8.

- Crimp or split key for 10.

- Liquid VD - 40.

- Metal brush.

- Small hammer.

- Transparent small bottle with rubber tube.

How to choose a hose which brake hoses are better

As a rule, brake hoses can be divided into two types - rubber and reinforced.

The reinforced hoses have two layers: an external - special metal network-braid and an internal - plastic tube of reinforced strength.

The metal network will not allow the hose to deform and has a different structure in comparison with the steel grid in rubber hoses, so it is considered more reliable. This hose design makes it possible to efficiently monitor the braking process. The lack of these hoses - the reinforced surface can scratch everything around. It is about this that most manufacturers are applied to the hoses a third transparent layer of PVC.

At first glance, rubber hoses are simple, however, in fact, they consist of three parts and quite reliable. The rubber inner hose coating holds inside the brake fluid. The next coating is a steel grid that does not allow the hoses to deform due to pressure. The third layer is a thin rubber coating that ensures the moisture resistance and flexibility of the hoses. Rubber hoses are sufficiently wear-resistant, however, it is believed that the braking system is slower from behind them. This occurs as a result of the fact that they are subject to deformation a little more than reinforced.

Additional spare parts and consumables

Together with the hoses, it is necessary to purchase copper washers. One washer goes on one hose. The required thickness of this copper sealing washer is 1.5 millimeters. We should not forget about the brake fluid that will be needed after pumping the system for replacing hoses.

How to remove the brake hose, step by step instructions

- Initially, it is necessary to lift the vehicle by jack and remove the wheel.

- Then, from the pumping fitting, it is necessary to remove the rubber ring and the protective cap.

- Remove the pumping fitting.

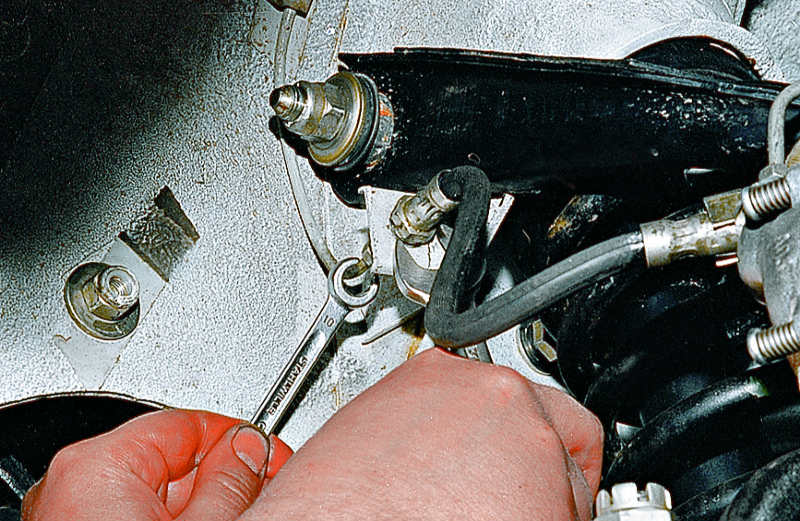

- Now we take over the brake hose. I put the crimp key on the brake tube fitting, hold the brake hose and tear off the fitting. If it is difficult to move, tighten it, pour the VD - 40 and try unscrew again. When the fitting of the tube is freely rotated, the crimp key must be removed and unscrew the tube fitting using a horn or split key. In order to avoid the loss of the brake fluid, the tube should be dried with a rubber cap.

- Now it is necessary to remove the rubber ring of the hose from the depreciation front rack holder.

- From the brake cylinder, unscrew the brake hose.

Pumping fitting, how to unscrew it and what to do if unscrewed

As for the pumping of pumping, they need to do in the first place, because the fittings of the front caliper of the VAZ vehicles have the property practically tightly accumulating.

And if you try to unscrew it and pump the system, it just breaks out. This happens quite often and, at the same time, it will not be possible to pump the system.

The most faithful, fast and safe way to solve the problem is the complete replacement of the front caliper brake cylinder.

Installing the brake hose

In the place where the hose and the caliper is connected, it is necessary to carry out wastewater, as oxidation, dirt and sand do not contribute to hermetic compound.

Now screw the hose with a sealing washer and gently tighten. Connect the hose and brake tube. Then in the holder of the rack fix the brake hose.

Pumping brake system

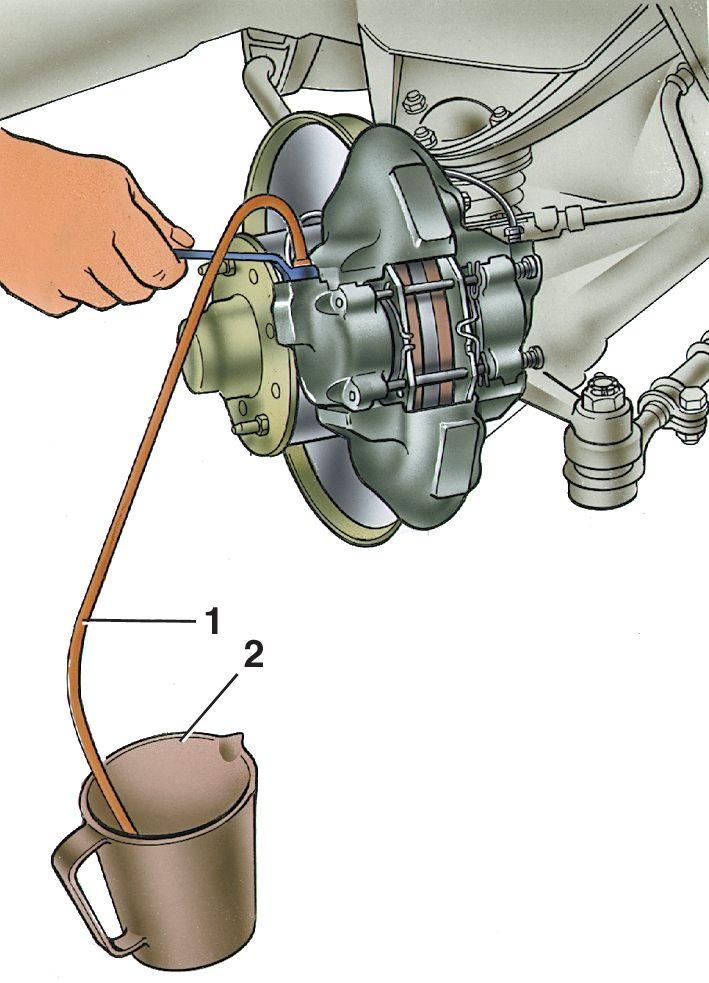

To pump the system you will need an assistant. We ask it with an interval in two seconds three or four times to press the brake pedal, after which it needs to be held.

1 - hose for pumping; 2 - vessel for brake fluid.

At this point, you must let go of the pumping fitting so that the fluid with the air began to go out. It is clearly visible in a transparent bottle. Now you need to tighten the fitting.

The procedure should be repeated until there is a liquid without air bubbles. Now it is only necessary to check the level of fluid and tightness of the compounds.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments