The purpose of the generator is to provide power to all the included voltage consumers with a motor-headed. Like any unit, the generator is able to wear out, while often car owners have to replace bearings. About this further in the article.

Content

- VAZ generator device and principle

- Where are the generator bearings 2110

- Signs of Malfunction of Generator Bearings 2110

- Causes of the failure of the generator bearings

- Diagnosis with your own hands

- Generator 2110 scheme in assembled and disassembled form

- Choosing a workplace

- Tools, fixtures, consumables

- Dismantling and generator disassembly (detail)

- Replacing the front bearing generator 2110 (step by step)

- Replacement rear bearing 2110 (detail)

- Tips Pros: how to find out what bearings are on the VAZ 2110 generator

VAZ generator device and principle

The main consumer of electricity at the start of the power unit is the starter device, the current strength in this case reaches hundreds of amps, resulting in a significant drop in the battery voltage. In this mode, consumers feed exclusively from AKB, which is intensively discharged. After starting the motor, the generator device becomes the main source of power supply.

The generator is a source of constant recharging of the AKB when the engine is running. If the generator stops working, the rechargeable battery is quickly discharged. The generator device provides the necessary current for the operation of the electrical appliances and the battery charge. After recharging the battery, the voltage difference of the generator and the battery becomes small, which entails a decrease in the charging current.

In terms of including powerful consumers (for example, headlights or rear window heater) and small motor revolutions consumed the total current can be much more, thanks to give the generator. The load in this case will fall on the battery, and it will start discharged.

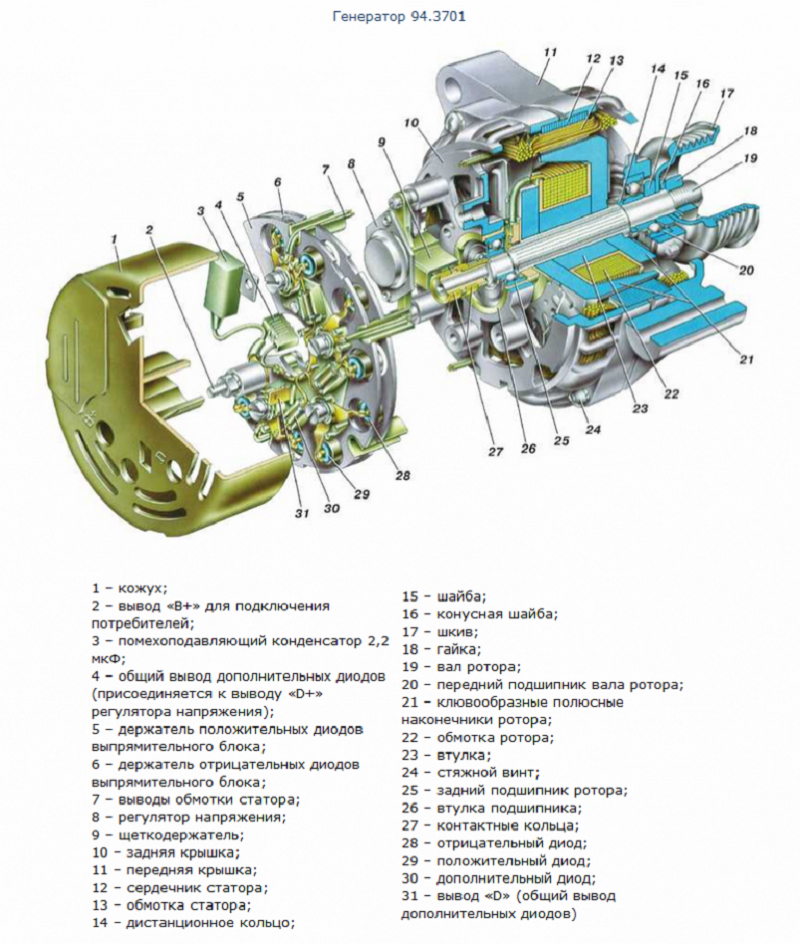

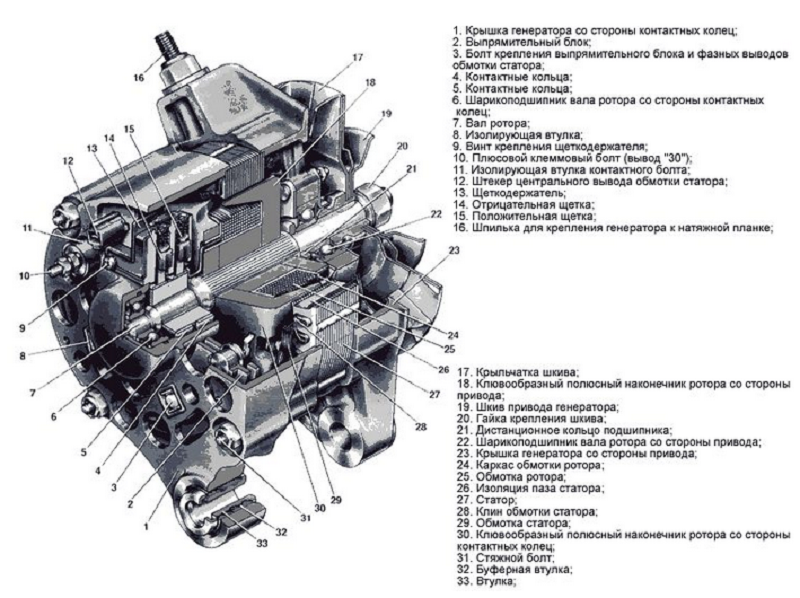

Structurally, the generator consists of: housing, stator, rotor, rectifier block, brush node and control device.

Where are the generator bearings 2110

Generator bearings are used to ensure uniform and smooth rotation of the rotor. In the VAZ 2110 generators, two bearings are applied - front and rear, which are under special lids. To get to them, you need to dismantle the generator and remove the protective covers.

Signs of Malfunction of Generator Bearings 2110

The main signs of wear of bearings are:

- Uncharacteristic whistle and hum after running the motor.

- The battery is unstable, which is due to problems in the functioning of the shaft.

- Overheating devices due to friction of worn items.

- Shipping.

Causes of the failure of the generator bearings

The output of the generator bearing can occur for such reasons:

- Some components of the structure of the structure were worn due to a long operation (rolling track surfaces, rolling elements, separator, sealing component).

- The lubricant ended in the bearing device, which may occur as a result of its leakage.

- Device wear and low accuracy of the product may result in a rotation of the outer clip on the housing or the inner rope on the rotor shaft.

- Malfunctions in the work of bearings can also be due to the abrasive elements inside them. This problem entails an increased creak.

- It is possible that the bearing output is due to the fact that the detail simply worked out its operational resource.

- Another possible reason is the wear of the strap or imbalance itself.

Diagnosis with your own hands

To check the performance of bearings, do the following:

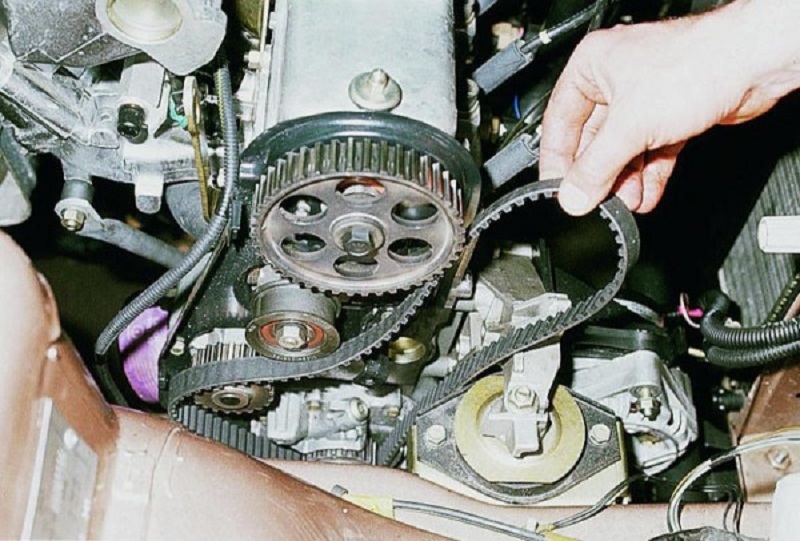

- Remove the belt from the pulley.

- Run the motor.

- If, after starting the engine, the whistle, hum and other symptoms are disappeared, this indicates the need to replace the device.

Generator 2110 scheme in assembled and disassembled form

Choosing a workplace

To dismantle the generator and the subsequent replacement of old bearings, put the car so that it is good lighting over the hood to remove the mechanism without difficulty.

Tools, fixtures, consumables

During the work on replacing bearing, you will need such tools:

- Passatia.

- Hammer.

- Vice.

- Marker.

- WD-40 liquid.

- Two-contact puller with paws.

- Minus, cross screwdriver.

- Heads with a rattling and keys on 13, 10, 27, 8 and 17 - better two.

Dismantling and generator disassembly (detail)

Order of work:

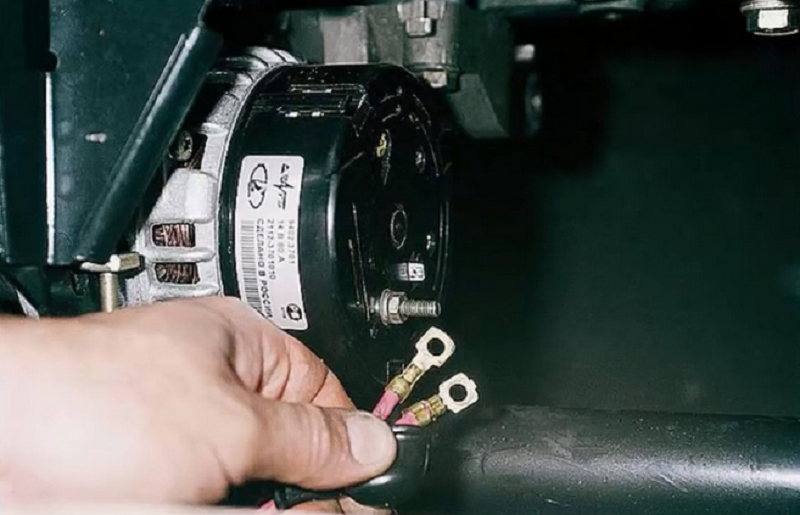

- Disconnect the minus terminal of the AKB.

- Next, unscrew the terminals of the device itself, pre-unscrewing the attachment of these terminals.

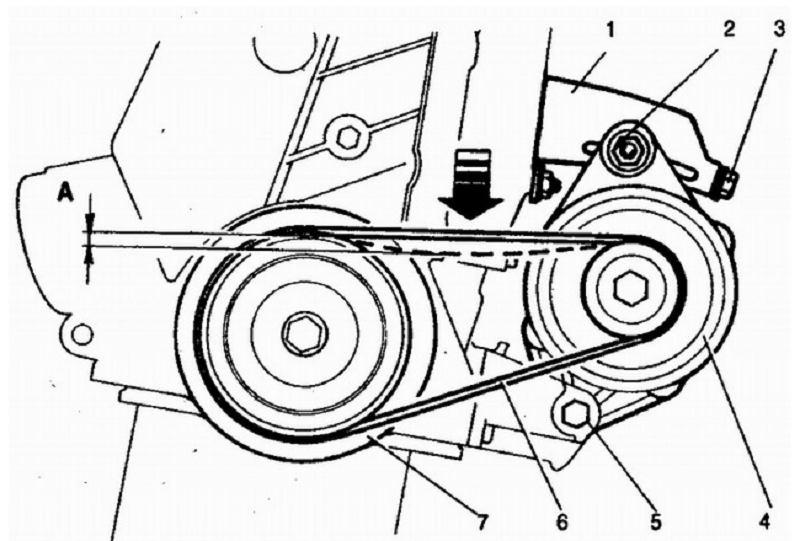

- We study the generator fasteners scheme to begin withdrawing the unit.

- Then remove the crankcase protection and remove the car.

- Next, unscrew the mounts fixing the generator to the frame (on the position scheme 5 and 2).

- During the revealing of the last fastener, hold the mechanism with your hand.

- Remove the unit, remove the dirt and wipe the rag. Lubricate WD-40 threaded connections.

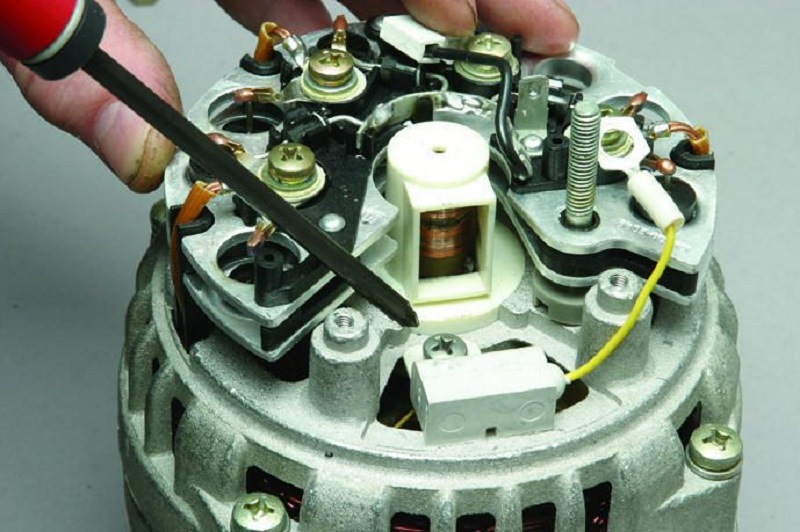

- Screwdriver remove the rear plastic lid on the generator.

- Cross screwdriver Unscrew the voltage regulator and attaching the brush holders.

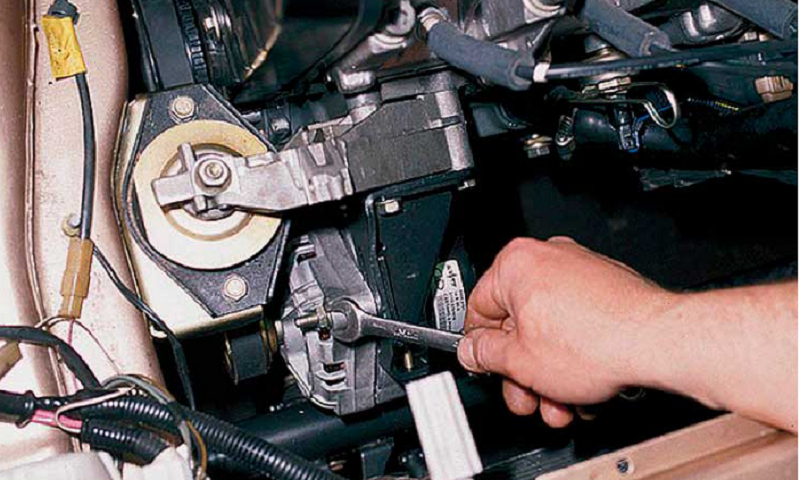

- Remove with the axis pulley and clamp the product in the vice.

- Droke or other key, unscrew the nut on the pulley. So that the shaft is not scrolled, insert the hexagon into a special recess on the end.

- Remove the washer and, by reloading the corresponding bolts, disassemble the unit of the unit.

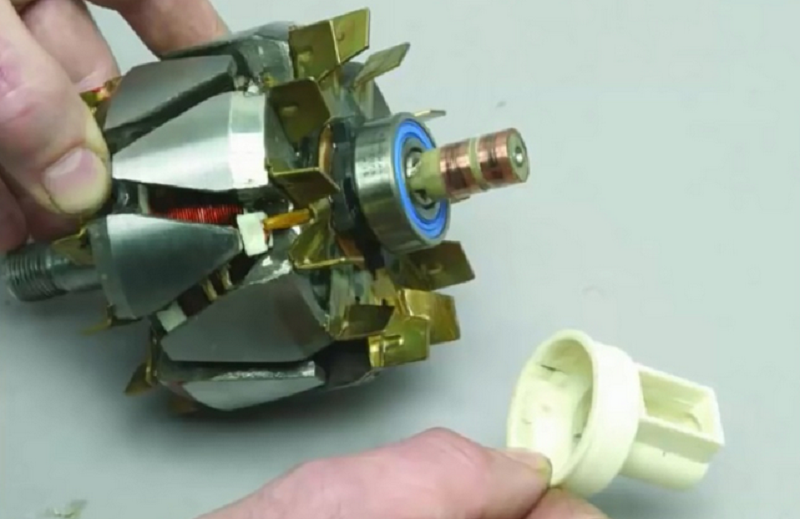

- Remove the plastic casing, and then the front ball bearing to gain access to anchor.

Replacing the front bearing generator 2110 (step by step)

Order of work:

- As practice shows, the rotor from the front bearing is more convenient to shoot in this way: you screw the nut on the rotor thread and hit the hammer on it, substitting the wooden paler.

- We find an element, the diameter of which corresponds to the diameter of the removed bearing (a 27 mm head is suitable).

- Carefully tapping on the element to knock the bearing from the landing place.

- I processes the lubricant new bearing.

- We take the old bearing, put it on top of the new and install with light blows with a hammer.

Replacement rear bearing 2110 (detail)

Order of work:

- To dismantle the rear element, you will need a special puller.

- In the absence of a puller, you will have to knock out a chisel element.

- With the help of a chisel, apply a hammer over the bearing. Important moment: on the surface it is necessary to move in the opposite direction.

- We take the head with which the front bearing was filmed, as well as the old extracted generator bearing. With their help you score a new bearing on its seat.

Tips Pros: how to find out what bearings are on the VAZ 2110 generator

This question can be answered, knowing such characteristics of the TC:

- What year of the TC?

- Injector?

- 16 valves?

- Rear or front bearing?

In the Land-Year VAZ 2110 generator, components of other size and marking are installed, since the diameter of the rotor axis is different.

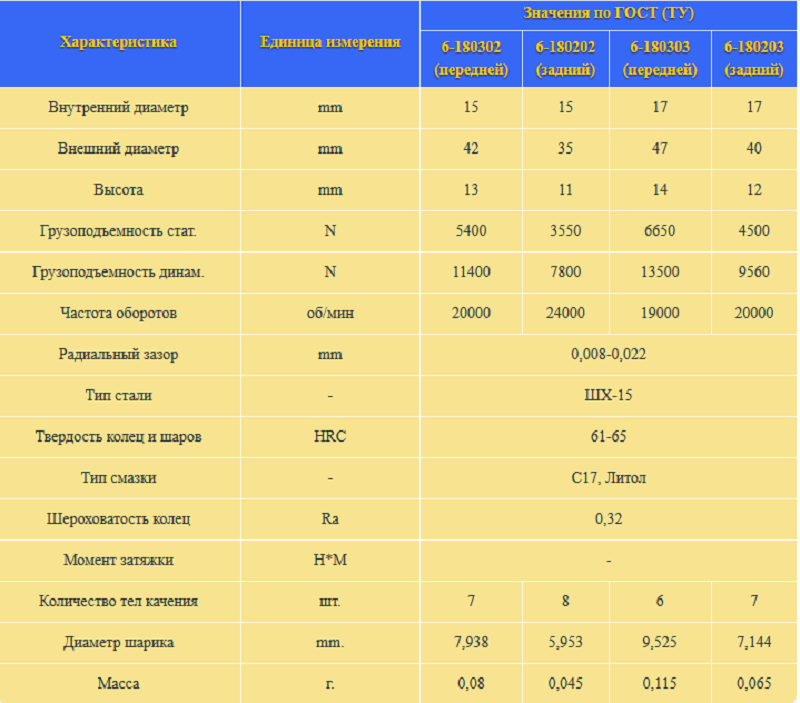

Bearing by GOST number (front and rear):

- 6-180302 and 6-202 - Late models.

- 6-180303 and 6-203 - new models.

To accurately determine the marking of parts, before buying bearings, make measurements of product dimensions and measure the rotor, then compare the received information on the table.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments