Steering thrust is an integral element in the steering drive of the vehicle. Her main task is to prevent the side sliding of the wheels when the car makes a turn. If the operation of the device is correct, the driven wheels of the machine must be rotated in different angles, while the external wheel is required to rotate to a smaller angle, and the internal one is in large. Such a drive can consist of various crags - left, right and medium, as well as from right and left wheeled levers. Depending on the model and type of vehicle, there are quite a lot of diverse drives, but not all of them are suitable exactly to your car model. For this, it is necessary to carefully approach his choice, to prevent errors when installing, because the replacement of the steering thrust should be carried out strictly according to a specific type of machine.

Content

Steering thrust, device and work principle

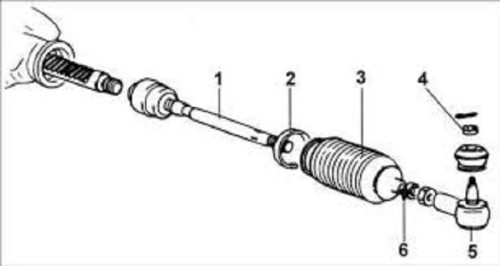

Although there are a lot of constructive features for a variety of automotive models in this compound element, the meaning of the actuator remains unchanged. The link between the lever of the desired mechanism and the longitudinal part is made using hinges. When the sushka turns, the average thrust moves to the left or right, and the wheels turn into the required direction with the help of side loads.

There is also a plate-type mechanism, it is simpler in its organization and is mainly different with the use of two steering thrust, which cause the vehicle wheels to rotate in the desired direction and interconnected with swivel levers using minimal effort from the motorist.

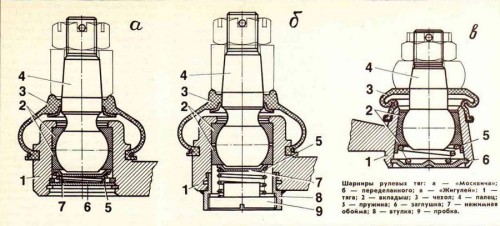

Hinges or tips of steering, are they refined to repair

Tips or steering hinges are considered the main part of the steering thrust. Their main task is to qualitatively and firmly connect with threaded tips. They look like hemispherical fingers and very fragile. It is possible to replace the hinges in full assembly, because they cannot be repaired or restored. Must with trouble in the future can be replaced by steering tips on both sides.

Steering thrust faulty, signs of fault steering thrust

The main features of the malfunction can be called:

1. If the steering wheel beats or vibrates inadvertently.

2.If when driving a vehicle, you hear unplanned knocks, usually coming on the right side.

3.If the back of the steering wheel is uncharacterically increased and the driver feels changes when driving a car.

4. If the steering wheel is too tight on turns and arise with control.

5. If with rectilinear movement, the movement of the vehicle spontaneously deviates to the right or left.

In the case of one or several signs of the breakdown of the steering thrust, it is necessary to diagnose as quickly as possible and the subsequent replacement of the tip in the steering rod.

Diagnostics of steering tips do it yourself

Whatever the operation of steering tips, it is not necessary to contact the workshop, each motorist can perform it yourself, if it is accuracy to follow the detailed instructions below.

With independent diagnostics, you need to pay special attention to the following items:

1. If you see that the steering tips move along the finger axis more than one and a half or two millimeters, it means that you need to replace the tip with the hinge.

2. Superfect that the clutch clamps are tightened with the necessary force.

3. It is possible to check the degree of strength covers that protect the tip hinge. In case of cracks and breaks, the case must be replaced.

The most characteristic and most popular breakdown of the steering wheel can be called damage or wear of the hinge tip of the steering thrust.

To determine malfunctions in the management, you do not need any equipment or tools, you will only need to put hands on the steering wheel and "listen" to the movement of the car. Often, experienced motorists are able to immediately detect changes and non-standard vehicle movements.

There are two ways to detect problems:

1. When the car is worth, try twist the steering wheel and see how the wheels react. If the steering moves do not match the movement of the wheels, this is a clear sign of faults.

2. Look, whether there are no cuts on the roof, scratches, cracks or peels. If there is, it is necessary to replace it.

Tools steering helpers

1. For the beginning, you need to purchase thrust that are suitable for your brand and car model.

2. Reel the steering thrust.

3. Rotten.

4.OMkrat.

5. Slippers.

6. Office wrench.

7.Universal technical fluid.

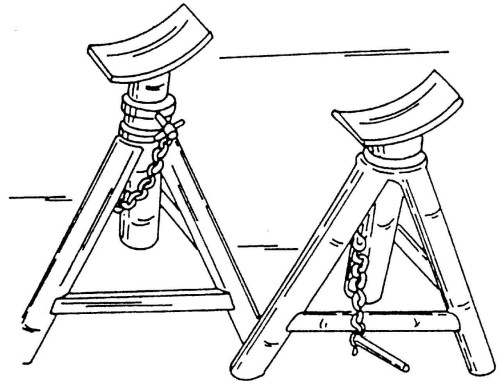

8. Cames for safety.

Replacing the steering thrust yourself, work stages

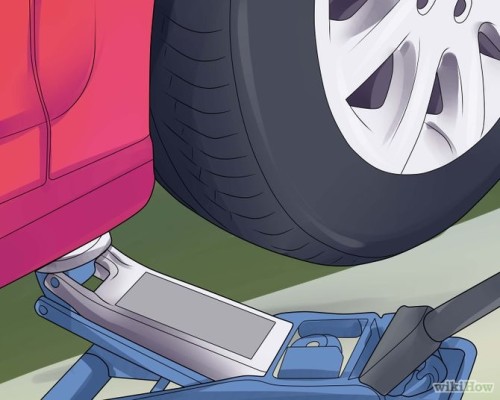

1. After changing steering thrust, you need to move the vehicle to the observation pit to provide access to the necessary mechanisms.

2. Dealer we raise the handbrake with its subsequent fixation.

3. Block the steering wheel and de-energize the battery.

4.Pripping the car with the help of a jack and exempt the place under the goat.

5. Singing the wheels.

6.Schelving of the nuts of the tips and unscrew them.

7. Remove the puller. We beat the hammer on the turn of the swivel lever and tighten the nut closer. We repeat the procedure if the position of the lever has not changed.

8. Cover from the coupling the steering tip. Due to the pre-disconnection of the battery, the ability to get on the plus wiring can be excluded. If the thread rusty and the necessary item will be badly separated, it is possible to use technical fluid.

9.Deternably dust, and unscrew the craving from the steering rack.

10. The kit should be lubricant, it is necessary to lubricate the hinge.

11. Start a new steering craving without using the hammer and without applying complex physical efforts.

12. Include the battery, fix the brakes and check it all on working capacity.

13. Independent on the size of the new and old element, it is required to make a note in order to technically correctly fasten the craving and get to the workshop without difficulties. In the future, on these labels, the service center master will make you the collapse of the wheel convergence. To avoid trouble with collapse, you need to calculate the number of revolutions, you need to unscrew the tip.

14.If ultimately produce the procedure of wheel constructions, it will save you from buying extra rubber in the future.

Check quality performance

Check quality performance

1. When checking should not be the backlash in the traction.

2. Whether the regulation of the backlash is needed on the steering wheel, it must be about fifteen degrees.

3. The steering steering should be smooth and continuous, and the number of revolutions to the left or right should be equal.

4. Opens that after turning the steering wheel returned to the place.

5. Appreciated 600 kilometers to spend another adjustment. But, if problems arose during adjustment, then re-performed immediately.

In case of determining the problem in the early stages, as well as, performing work strictly at the above points, the procedure for replacing the mechanism should not cause difficulties and is performed quite quickly. True, difficulties may arise when buying the necessary parts, as if the car is old, then some details can be removed from production. If you are not sure of your abilities, specially trained workers in the service center will make all the work for you, however, for these services will have to pay. Well, the choice is yours.

By the way, the longitudinal steering line is obliged to be located so that it is to be subjected to minimal axial movements when the wheels are moved. This is the main rule of a comfortable and convenient ride. It is not necessary to ignore the problems and postpone with the repair, since due to disruption of the angle of convergence, the rubber will not live long, and the chances of getting into the accident significantly increase.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments