Suspension of any vehicle is always the first to take a blow from irregularities on the road. For optimal perception of these irregularities, it is equipped with elastic elements, which using a transverse beam, redistributing the accepted efforts, shift the wheels. This system, which consists of levers and beams, is called a transverse stability stabilizer. Its appointment is to maintain the stability of the car during corners or other external efforts.

Content

- Car suspension, device and principle

- Stabilizer of transverse stability, installation location, device assigned tasks

- Stabilizer bushings why they are destroyed, signs of destruction

- Danger of car operation with faulty stabilizer bushings

- How to check the quality of the bushings

- Tools, fixtures, consumables

- Replacing cross-stability sleeves with their own hands (step by step)

- Tips Prof.

Car suspension, device and principle

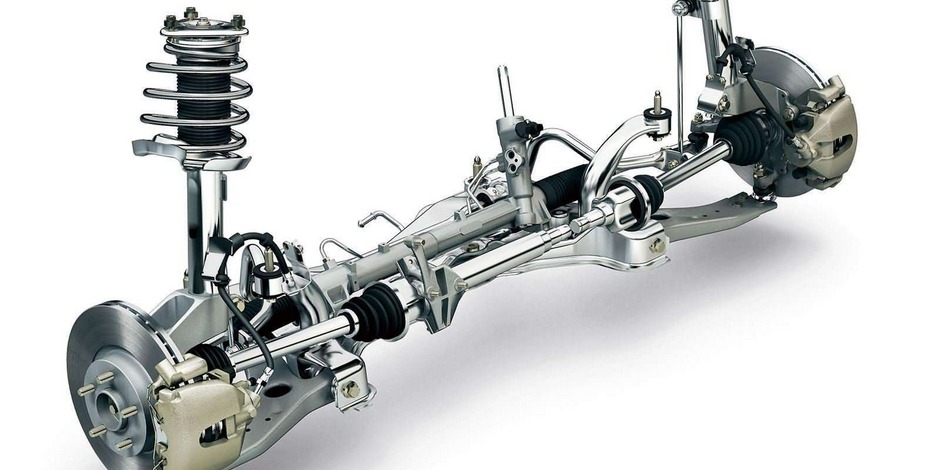

Common elements for all types of suspension are:

- Power distribution components.

- Components of ensuring elasticity.

- Components of transverse stability stabilization.

- Quenching component.

- Fasteners

Components of ensuring elasticity They are a kind of buffer between the vehicle body and road irregularities. This includes torsion bars, springs and coil springs. The springs are of variable rigidity and constant. Suspension is a set of elastic strips of metal which are tightened kind of "ladder" and have different lengths. Torsion bars are a metal pipe in which the rods are functioning according to the principle of twisting.

There is another type of elastic components - hydro-pneumatic and pneumatic. The first is a symbiosis of compressed air and working fluid in one chamber, which is divided by a partition, a second action based on compressed air properties.

The components of the distribution direction of the force simultaneously serve for fastening the suspension to the car body, force transmission body and proper location of the vehicle wheels relative to the body horizontally and vertically. Data features include a double leverage, leverage the longitudinal and transverse installation.

extinguishing components (Dampers) are used to counteract the elastic components, namely for smoothing fluctuations. Structurally, the shock absorbers are in the form of a metal tube with fixing elements and apply the principle of the hydraulic resistance. There are two types of shock absorbers - monotube and twin tube. According to the method steps are shock absorbers, oil, pneumatic and gazomaslyanye.

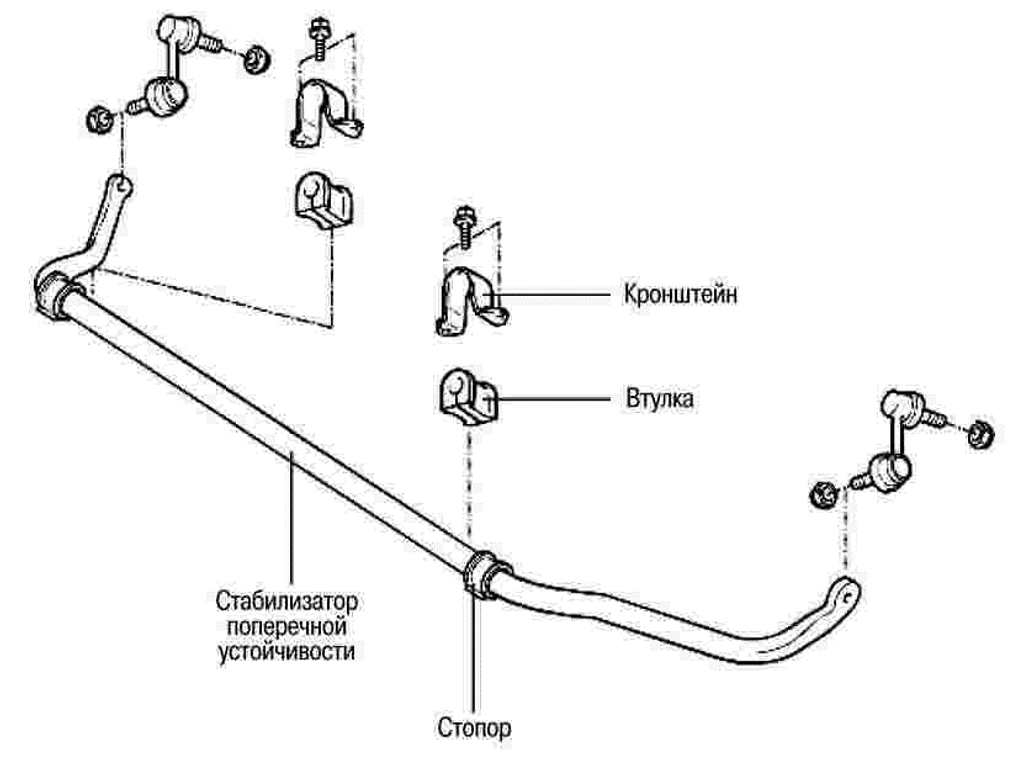

Components stabilizing transverse stability - bar with fixing pillars to the car body, which connects the levers opposite wheels. The components are designed to reduce roll and lateral distribution of the load of the car when cornering.

Fastening suspension components vehicle to the body and supports the wheels is performed via bolted connections, ball joints and rubber bushes (rubber plugs).

Anti-roll bar, the place of installation, the device is assigned the task

Anti-roll bar is easy to see, if you put the car on a viewing hole or drive to the ski lift. On the front axle, including shock absorbers, springs and other levers you will notice a curved steel rod, which at its one arm is attached to the wheel hub, and the other - the subframe. fastening of the stabilizer are not rigid and allowed to move around in the same plane as the axis.

The principle of operation of the stabilizer based on the redistribution of the weight of the vehicle body on wheels under the appearance of the roll. For example, during a sudden change of trajectory driving and cornering with a small radius.

stabilizer bushings, why they break down, signs of destruction

For the maximum desired vibration damping and force effects that go to the vehicle body, the vast majority of suspension components connected by means of elastic elements. This applies to the anti-roll bar. special bushings are used to secure it (cushion gum), polyurethane or hard rubber.

Under the influence of time and a variety of factors, such as the poor state of the road surface, the use of aggressive reagents, driving style, and so on, data of the sleeve can begin to break down. As a result of this work the stabilizer becomes unsatisfactory. They may also begin to arise more serious defects.

The first symptom, boding replacement bushings - a slight knocking suspension. Such hammering can also be heard at the "tired" dampers. However, in the case of the bushes, he will be heard not only in the pits and potholes, but also when entering the sharp turns. The vehicle is not seldom felt too sluggish and rolls. Emerged knock will result appeared backlash in the connection units levers stabilizer because of wear sleeves.

Risk of faulty operation of the vehicle with bushings stabilizer

If you do not take action in time in the future knocks only be strong, and must accompany the work suspension due to the increasing destruction and bushings strain. It may be excessive play and steering cross-pitching of the body. Perhaps the "yaw" of the vehicle not only when cornering, and in the case of rebuilding or braking. Automakers usually recommend changing sleeve every thirty or forty thousand run. But in our conditions, it is desirable to focus on their wear. Therefore, suddenly appeared light chatter and clatter when cornering are clear symptoms of impending replacement of elements.

How to check the quality of bushings

There is a people's way to check the bushings of the stabilizer in good condition. It is necessary to drive a lying policeman "Decion" on the second gear. In the area of \u200b\u200bthe pedal, there was a deaf knock - most likely, the bushings were worn out. You can also just climb under the car and see everything yourself. On the worn sleeve, cracks and scuffs will be noticeable, which are characteristic of lightering and worn rubber. Sometimes the automaster also calls such cracks with "daisies".

In addition, the rubber of the sleeves can simply cry and lose the desired elasticity. If it does not work normally consider the sleeve, shake the stabilizer itself. The presence of a backlash, squeaks and knocks in the lower part of the suspension indicates that the stabilizer bushings were unusable.

Tools, fixtures, consumables

- Caid head.

- Gorog.

- Ratchet with extension.

- Rozhki and precipitant keys.

Replacing cross-stability sleeves with their own hands (step by step)

- It is necessary to post a car on jacks and secure securely.

- Next, remove the wheels.

- Remove the protection of the crankcase and the sneakers.

- Lift the bottom lever using the jack or put the focus on it. In the case of replacing the bushings from both wheels, it is desirable to put the stops under the an axis of the front wheels or take advantage of the jack. It is necessary to remove the load from the beam of the stabilizer and facilitate the further replacement of the sleeves.

- Then loosen the fastening of the stabilizer to the subframe or body (on both sides). If there are difficulties with bolts as a result of their oxide and contamination, process them with "WEDEshka" or other similar solutions to facilitate their unscrewing.

- Remove the fastening of the sleeve and the sleeve itself. To date, the bushings often make split, which significantly facilitates the procedure for their dismantling.

- Take a new sleeve and set the old one. Well wash and wipe the seat of the element on the stabilizer. You can also wash the sleeve a little to make it more convenient to move it or use the special lubricant that does not rarely go in Remkomplekt.

- Tighten the fastening bolts of the sleeve clamp.

- Remove the jack from the lever and install the wheel.

Tips Prof.

It should be understood that the suspension device on various cars can differ significantly and this instruction is not universal. However, for the general understanding of the procedure and the procedure for performing work, it is quite enough.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments