The adjustment of the gaps of the auto engine valves is rather important, but at the same time, a simple procedure that will allow you to save your funds, as it costs a lot to a hundred. Self adjustment of the valves will help you customize the motor in such a way that it will always work like a clock.

Content

- Adjusting the engine valves, and why regulate the valve

- Thermal gaps of valves, how to find out the size of the thermal gap of your own car

- Adjusting gaps, how often the adjustment of the gaps

- Probe gaps, what is it and what information is on this instrument

- Adjusting valve gaps, step-by-step instructions

- Measuring the gaps of the diploma, detailed instructions, advice of professionals

- Adjusting thermal gaps, how to adjust the gaps using the rail with the indicator

Adjusting the engine valves, and why regulate the valve

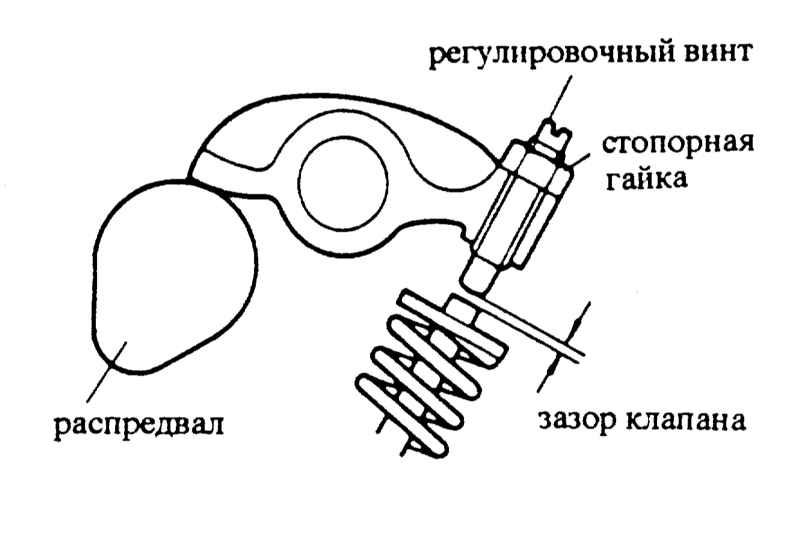

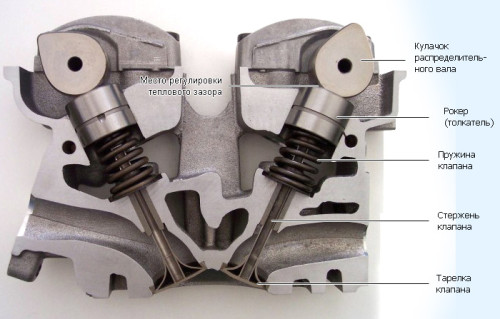

When adjusting the valves, it is necessary to know that one cylinder has two or more valves. In the valve mechanism it is necessary to adjust the gaps that arise between metal elements as a result of heating. Before you start adjusting the valves, you must completely cool the engine, checking the gaps with a flat probe.

Self adjustment of the valves is necessary due to the fact that during heating, the gaps between the metal elements of the valve mechanism or decrease, or expand. In this case, the motor will not be able to work normally and start to knock, its capacity will fall significantly, the carburetor will "sneeze" and so on.

In addition, the wrong and bad adjustment can lead to more serious consequences. For example, the efficiency of the motor operation will decrease even more, as a result of which premature wear of the elements may occur. If the gaps will be too small, the valves and their saddles can burn. With large gaps, you can see the knock of metal elements and other signs.

Thermal gaps of valves, how to find out the size of the thermal gap of your own car

Data on the sizes of heat gaps can be found in the manual for the vehicle or in other sources, for example, on the Internet.

It is necessary to know that in a variety of types of cylinders, typical gaps for the graduation or inlet valve may differ significantly. And if you do not know this, you can make a serious mistake when adjusting with your own hands.

Adjusting gaps, how often the adjustment of the gaps

Valve checks must be carried out every 20-30 tons. Kilometers.

The passage of this kilometer does not indicate that it is necessary to adjust the valve gaps. Many manufacturers are used on vehicles Modern systems that do not require the implementation of such a procedure.

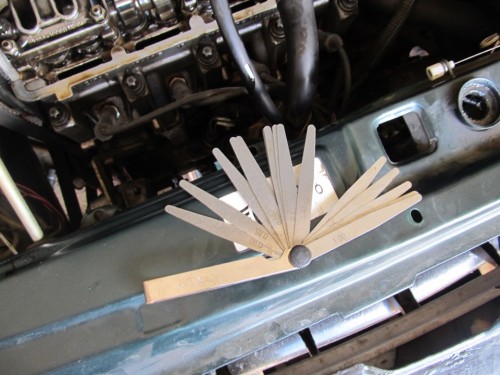

Probe gaps, what is it and what information is on this instrument

As already mentioned above, during adjustment, the vehicle motor should be cold. The gaps must be checked by a special flat probe optimal thickness. There are specialized tv rings, which must be adjusted. Some VAZ models are tuning using a special adjusting bolt head.

Adjusting valve gaps, step-by-step instructions

In this process, the Motor Valve Adjustment mode is important. First of all, it is necessary to unscrew the bond cover mounting nuts, and then remove it. Do not forget to remove the protective cover of the toothed belt.

To begin with, remove the ignition candles. Next, remove the oil in the head of special baths. Then carefully inspect the surface of the cams - for the presence of scratches, shells or other wear.

A tag on the pulley align with the installation protrusion, which is located on the rear protective lid. To obtain the desired result, rotate the crankshaft in a clockwise direction, while holding the bolt that crept the generator drive pulley.

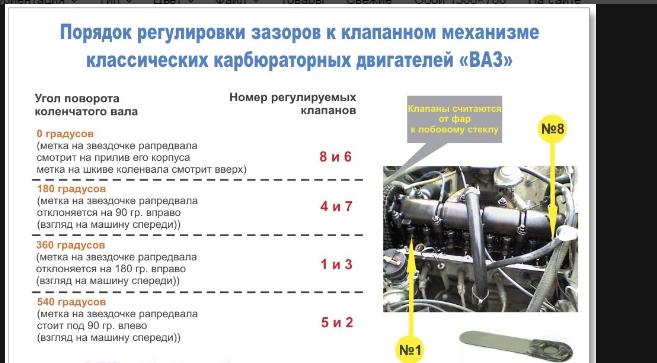

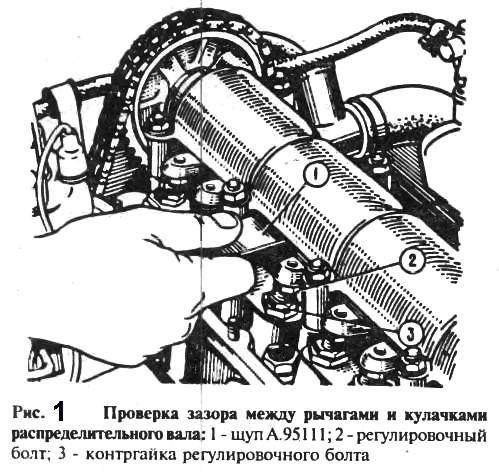

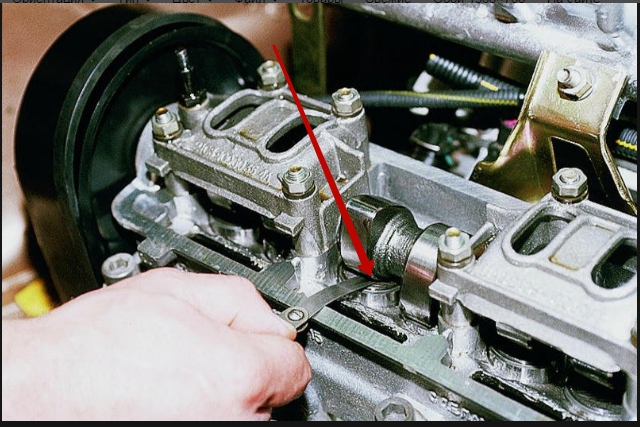

This position corresponds to the upper point of the required cylinders. Otherwise, end the crankshaft at fifty percent (2-3 teeth). After that, it is necessary to check the clearances from the third and first cams. It is desirable that the probe would not be prominent and not too loose, with a slight pinch. Otherwise, replace the washer.

Then you need to turn the crankshaft to the floor of turning forward.

Now check the gaps of the second and fifth cams. To check the cam 8 \\ 6, check the crankshaft on the half of the turnover, also for checking 4 \\ 6 cams.

After adjusting the valves, start the motor to check the efficiency of the operation. However, it is necessary to listen to the motor in different modes of operation.

Measuring the gaps of the diploma, detailed instructions, advice of professionals

The adjustment of the valve gaps must be carried out after mounting the cylinder into the upper dead point. In addition, both valves of this cylinder must be closed, but the rocker can move freely.

During the setup process, you need to release a lock nut, which is located on the bolt or adjusting screw. After adjusting the desired gap, we tighten the knockedy dipstick. Be extremely attentive, because the configured clearance after the wrong tightening may change. Therefore, you should check the gap again after the tightening. If the probe passes tight or too easy, adjust the gap more precisely.

Now it is necessary to align the gaps of other cylinders, turning half the crankshaft. It should be remembered that the crankshaft can be turned only clockwise, while holding the starter lever - the starter curve.

Adjusting thermal gaps, how to adjust the gaps using the rail with the indicator

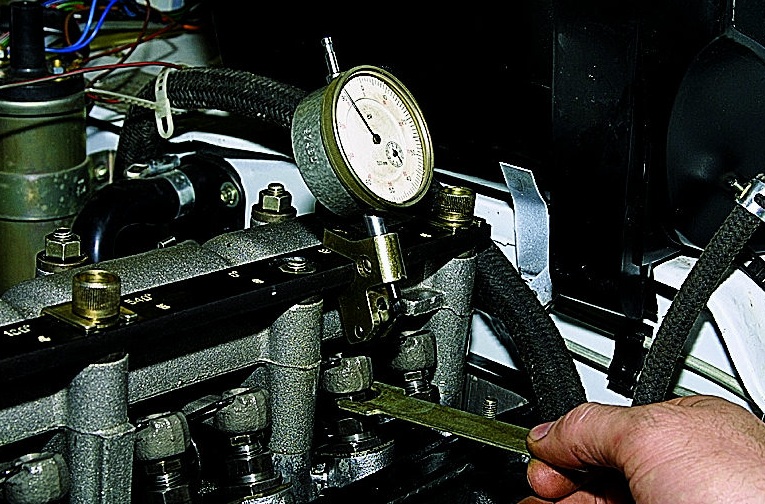

The results of the procedure will be much more efficient if used is not a simple probe, but a special fixture - a rack with an indicator.

The method of carrying out such an operation is actually the same as probe. However, there are some differences. Do not forget to check the gap after the setup.

More information you can learn from this video.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments