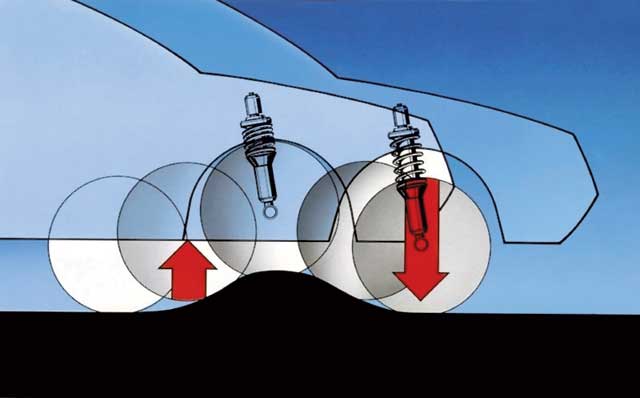

The role of shock absorbers in the car is large enough. Their task is not only to provide a comfortable pastime behind the wheel, but also the maximum sustainability on the road. Consequently, the level of vehicle manageability depends on their quality. Structure suspension It implies the presence of a spring, which carries out neutralization of jesters and shocks. Also, mitigation occurs due to tires. But without the device under consideration, it is impossible to achieve due results. They control the spring mechanism, taking over the oscillatory energy.

Content

Types of car shock absorbers

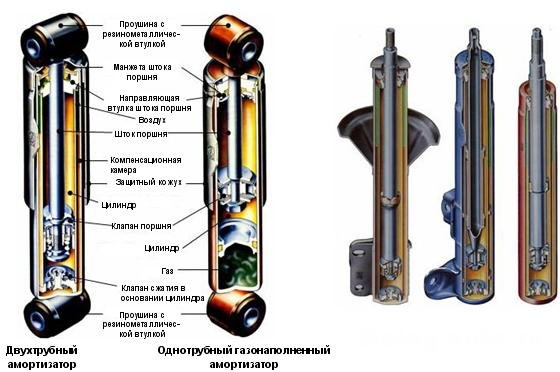

The most common shock absorbers consist of two cylinders.

Hydraulic two-pipe mechanisms are classic devices, as they have been developed for a long time and are used quite a long time.

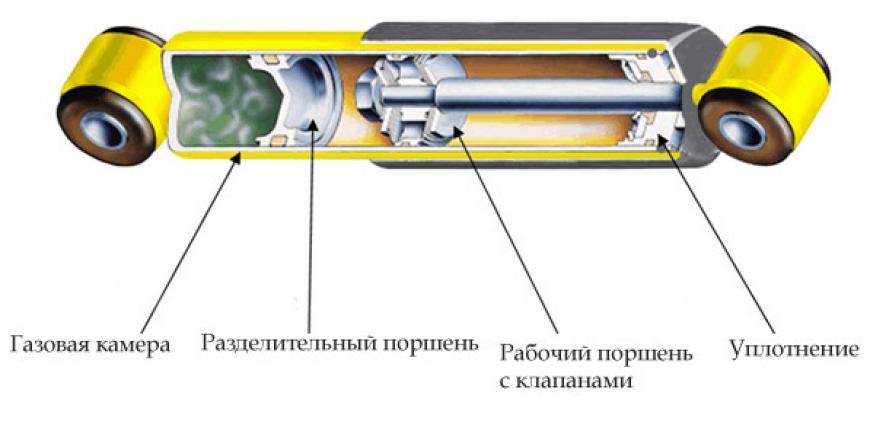

It will be about gas shock absorbers, the structure of which implies the presence of one pipe. But the difference is not only in this.

Here, a gaseous substance is used to eliminate oscillatory movements.

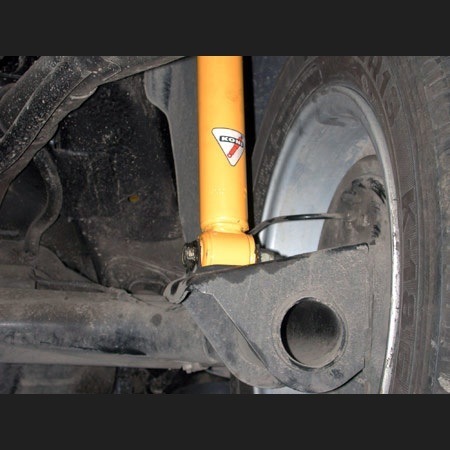

Use of gas shock absorbers

Since the structure of gas shock absorbers is very different from oil, then the leak is excluded, which is a big plus.

In the oil shock absorber, as a result of the loss of piston impermeability, the leaked oil can cause its damage.

Also, with increasing temperature, the beneficial properties of oil are lost, which leads to a decrease in the efficiency.

The use of gas shock absorbers leads to a decrease in the comfort of driving due to increased rigidity suspension car.

This is due to their rigidity.

If you increase the gas pressure, the reaction to the load becomes sharper.

Due to the gas density, the movement of the rod is hampered.

In this regard, their use is distributed in the world of motor sports, or motorists who close their eyes.

Most of the important systems of the car are installed with maximum care, the installation of shock absorbers is not an exception.

If you do everything in accordance with the rules, the service life can be extended to four years.

A periodic inspection of the car plays a seriously important role in durability.

The quality of driving will contribute to the preservation of shock absorbers in a working condition of a longer period.

Shock absorbers are replaced if the car functionality deteriorates.

This includes a reduction in the braking path, a decrease in speed when maneuver, which would ensure safety.

Also, if you have to reduce the speed during the operation of the car in rainy weather.

Professionals recommended checking every 20,000 km run.

Replacing gas shock absorbers, general provisions

Replacing shock absorbers separately is not recommended.

This will contribute to the violation of the coordination of the car, due to the pressure difference, and indeed the principle of operation.

Thus, the main functions are reduced.

To avoid possible consequences, you should familiarize yourself with the technical documentation for the car where information on replacing shock absorbers.

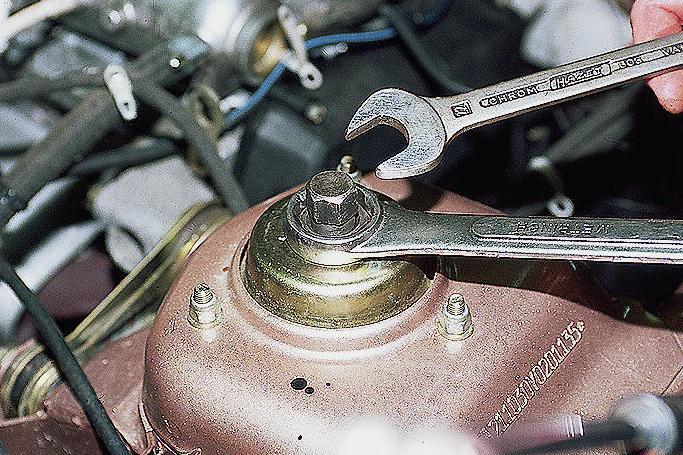

The car is installed on the observation pit or hangs on the lift, only after these events proceed to replacing the shock absorbers.

After conducting an inspection, the central nut on the rod slightly unscluded.

The removal process is recommended separately, i.e. one shock absorbing device or one rack.

This is due to possible damage to the hinges of the suspension or brake pipes.

Estimating the rack, the reservoir is cleaned from alien elements.

Previously, before installation, the control check is carried out for the presence of oil or antifreeze in the tank, there should be no matter there.

Also, it is necessary to inspect the additional details that are set back.

Their integrity is checked, if necessary, replaced.

If installing a welded cartridge, an obstacle is felt, then the likelihood of changing the reservoir form is great.

Here it is more expedient to increase its hole for assembly. The rod nut is twisted to the end, only after the car becoming on the wheels.

By putting a car, you should carry out manipulations that will lead to swaying it along the vertical axis.

Next, with the help of a key with a built-in dynamometer, hinges and sleeves are tightened.

After completing the installation, the system is checked.

For this, the car is in front or rear raised.

After the ridden part of the part itself fell, the length of the segment between the bumper and the floor is set.

After, also with one of the parties, pressing and, accordingly, measure the same segment.

The difference between the established data should not be more than 1.5 cm. In the opposite case, it is necessary to take measures to identify the causes that lead to the occurrence of friction.

In order not to have arisen when installing, a preliminary check of the components of the suspension is carried out.

Here are the details that are as used as possible in the work, as a result of which are exposed to greater wear.

Because of the formation of a gas pillow, extraneous sounds occur. In order for them to have no pumping.

Pumping shock absorbers before installing

For five seconds the device turns off the rod down;

Compression and again five-second expectations;

After, it turns over, in the compressed position, in the working. After which it is necessary to wait for the same period of time;

It is necessary that the rod rose a little, while he holds his hand;

The process is repeated several times.

By pumping the shock absorber, its position should be vertical, up to installation.

It is recommended to replace the oil for cooling, after each change of the details of the depreciation system.

This is due to the occurrence of condensation.

In the winter period of time, due to such formations, it is possible to fail the system, as the moisture, crystallizing, prevents proper efficiency.

As a replacement, we promise to use those that are issued by the same manufacturer.

Although there are interchangeable shock absorbers, but another brand.

Someone from a suitable shock absorber tries to do something similar to the native device.

In order to save, they are customized in size.

This is not the most reasonable way. The device is shortened or extended.

Of course, this will affect the quality of these products, but the main thing is to jeopardize the safety of operation.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments