The flow of brake drums, also called the boring, restores the surface layer of the metal, by eliminating the defects and irregularities of the car formed during the period of operation. After that, the working surface is restored. The required to remove the layer for all models is different. Today, this work is trusted by professionals a hundred, but is it possible to implement the process yourself? Consider this below.

Content

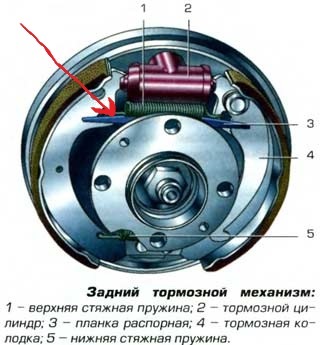

Car braking system, brake rear drum

Most of the car has a braking system located on the rear wheels.

Its structure is due to the presence brake drumwhich is equipped with automatically bred pads.

But the mechanism is quite strongly exposed to pollution.

This is facilitated not the best weather conditions, with the predominance of dirt and dust.

In such conditions, disruption occurs every 12-14 thousand mileage kilometers, depending on the degree of pollution of the place of movement.

With proper care, the risks of problems are reduced to zero.

Under departure, the drums are meant.

It is carried out by means of removing a small layer.

After replacing the pads, collecting the braking mechanism, the conditions under which the gap between the drum and pads is minimal.

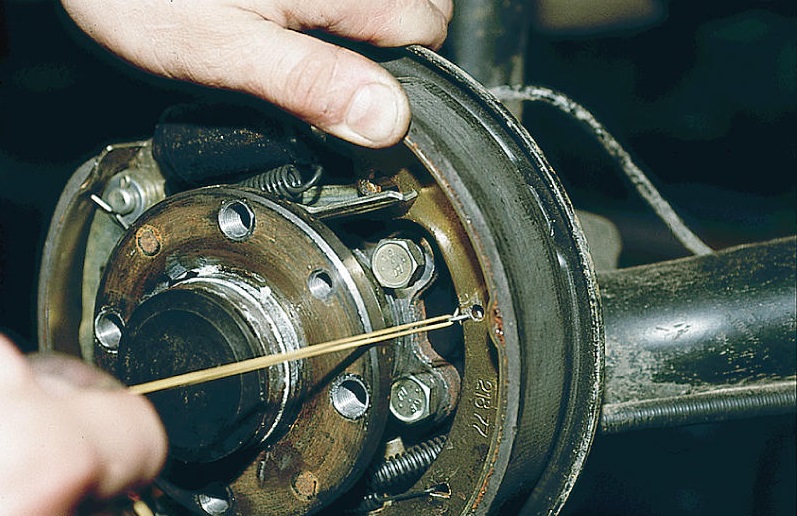

Pads brake rear VAZ

Replacing the brake pads is carried out when 80 thousand km of mileage is achieved. Technical inspection is carried out, overcoming 30 thousand km.

The car operated in urban environments is exposed to large loads, including the brake system.

It, because of frequent use, is experiencing significant overheating, losing its beneficial properties, which respectively reduces performance.

The structure of the brake pad is heterogeneous.

Being in working condition, strain arises on the surface of the drum, expressed in the form of grooves and grooves.

This anomaly leads to a rapid failure.

As a result, vibrations appear that reduce the quality of braking.

Brake system malfunctions

How to determine the reduction in the efficiency of the brake system?

Of course, first of all there will be significant changes as braking.

This is expressed in mitigating the process at which the braking path increases.

In addition to the main sign, shaking the steering wheel and pedals occur.

She can also be accompanied by vibration.

When the brake is involved, extraneous sounds are not characteristic of normal functioning.

The listed features are evidence of the loss of the performance of the brake system.

In this case, it is advisable to replace the brake pads or produce the drums of the drums, i.e., remove a small layer of metal or install new ones.

If the financial component allows, then the more correct way is to buy new details.

But the cost of the car is a serious budget item, which is only worth gasoline, therefore the need for saving.

Safety is above all, but the flow of drums is capable of ensuring it, saving money.

Therefore, in the people, this method has established itself from the best side.

The method of elimination that has spent its layer period is called a boring or dossil.

The part is fixed, and the defective layer is removed by means of grinding. The process is most often called preventive.

Piercing brake drum

Each company determines the boundaries on their own.

There are certain indicators of admissible removal.

This indicates the maximum possible thickness of the stratification of the structure of the drum.

If the details are original, then this information is indicated in the regulatory documents.

The process in question, despite the seeming simplicity, is a serious thing.

It is very important, conducting measures to bring the part to the working state, do not forget about the size of the central part of the system (hub) and adhere to the parameters with respect to it.

In the opposite case, the result will be an emergency. It is very important attention to.

Boring brake drum using machine

For borsts, you need a specialized machine.

It is even relatively recently, most motorists, to restore the drum performance, it was necessary to seek help from specialists.

Their dismantling and transportation to the repair point.

Specialists of the region, who know everything about this process, reanimated the details.

Without perfect equipment, this is a rather long and difficult thing.

Currently, machines are more developed.

Their equipment implies computer equipment, by means of which the processing parameters are specified.

There is no human factor here, which helps to reduce errors.

Of all the above, we can conclude: the restoration of the drum by means of the turning machine is more profitable, and the safety does not suffer from this; Drum service time increases; The problems indicated at the beginning of the article are eliminated.

Independent grinding is possible, but for this you need to possess the appropriate machine and knowledge combined with experience.

If this is not, then the more profitable option will be the appeal to the professional.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments