Despite modern technology and the introduction, in the braking system, disks, the drums are still used on most cars. Thus, the issue of dismantling did not exhaust itself completely, its relevance is at the proper level.

Content

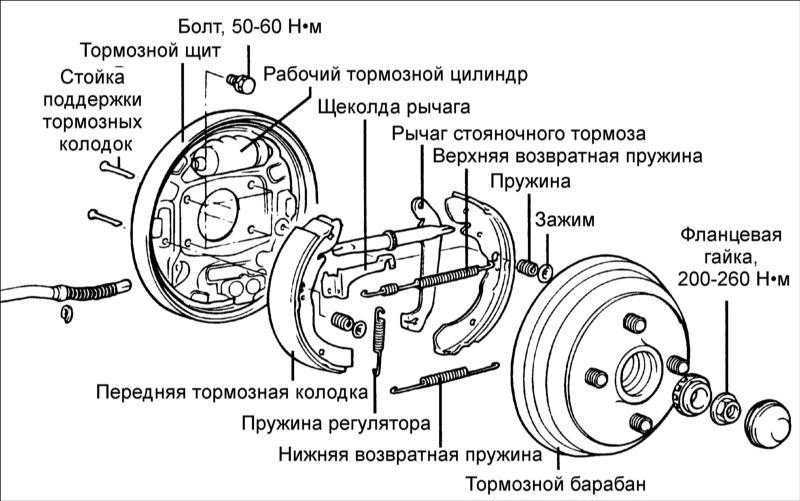

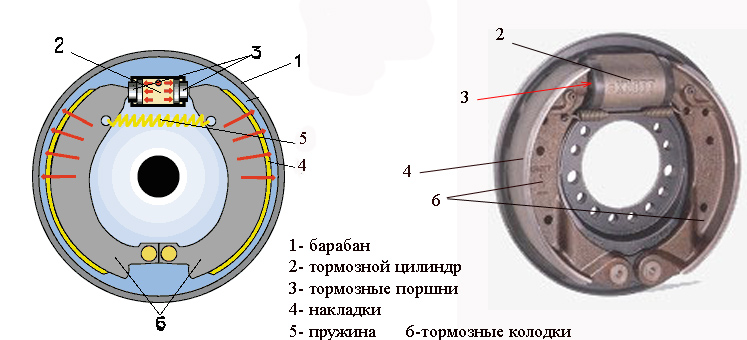

Rear drum brakes, building

To begin with, we will analyze the structure of the braking mechanism.

It consists of a fixed part represented as brake shoes and a part that rotates with the wheel while driving.

The drum is a rotating element.

The process of reducing the speed is carried out by interaction, i.e. the friction of the drum and the pads, until a complete stop.

The structure of the device, in general, is not complicated, besides the cost is acceptable. Drum-type brakes have mechanical self.

What it is?

This process is due to the special structure of the pads. Their lower parts are connected.

Thus, in the process of braking, the block that in front, interacting with the drum, generates an additional force.

This helps to use the rear pad, which increases the efficiency of the entire process.

Dismantling brake drum It is a common phenomenon in the world of motorists.

This is due to the conditions for its operation.

The condition of the roadway, humidity, driving style, accidents affect the reduction of functions.

As for the road, everything is more or less clear here.

But with humidity, the problems are more serious.

Without paying a proper influence of the system, the processes of formation of corrosion are possible, which leads to a decrease in braking quality.

The condition also affects the driving style.

Cars manufactured for the mass population and not adapted to aggressive control are quickly overheated, which leads to a decrease in functions.

One of the most serious reasons for reducing the efficiency of the brake system is a traffic accident.

Depending on its scale, relevant repairs are carried out. In some cases, a complete replacement of the system is required.

But mostly the considered factors work in aggregate.

As a result, ideal conditions are created for the occurrence of scratches, grooves and others. Defects.

Despite the experience of the car owner, the data of the "diseases" of the system is easily determined in visual inspection.

In parallel, the removal of the drum should be inspected by the pads, and in particular their brake surface, including special linings.

How to remove the brake drum

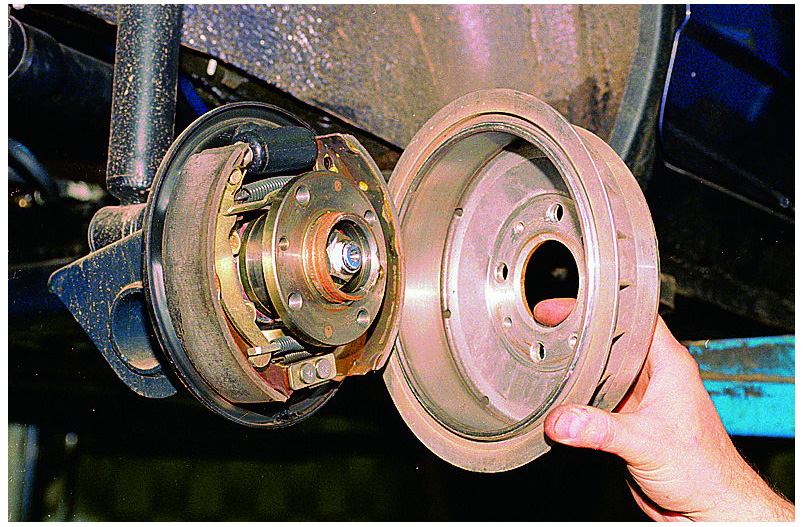

Having understood in the structure, it seems that the removal of the brake drum is not a particularly difficult matter.

But this is a delusion, with long-term operation of the car, brake drums sometimes, quite often, "burn", which very complicates their removal.

There are three basic methods.

how to remove the drum, brake drum 2107

To begin with, we will analyze the more rigid method.

The jack rises the side, from the wheel of which it is necessary to dismantle the brake cylinder. Other wheels are fixed. Then the studs are eliminated, the wheel is removed. The car is installed under the car bridge so that the position is stored unshakable.

After conducting preparatory activities, sit behind the steering wheel, turn the ignition key, set the third gear and we look at the tachometer.

When achieving 3 thousand revolutions, the brake pedal is clamped.

The breakdown of the drum is possible immediately, but if this did not happen, we try until you achieve due results.

The method has its own minuses, one of which is the risk of injury.

In this regard, it is not desirable to find unauthorized persons in the damage zone. But in this way it is not necessary to use, knowingly knowing that the drum in a faulty state.

pulmonary brake drums

The second method implies the presence of you already guessed the puller.

But here you will need a certain experience of using it.

Market conditions allow you to purchase it without any problems.

But possessing due knowledge, there is an opportunity for its independent manufacture.

It will be necessary to make components. The device is simple enough.

To assemble it, you need to use the services of metal processing masters.

The holder is manufactured, the basis of which is a prepared metallic cylinder.

Captures are mounted on the bolts to it.

To establish the desired sizes, you can use the information located in the World Wide Web (Internet).

There are all the sizes by which the details should be made.

The assembly does not represent special difficulties.

remove the brake drum, heating

The third method is used in the occurrence of corrosive processes, as a result of which the drum is not denied.

In this case, it is necessary to increase the temperature of the compound so that, accordingly, to carry out its gap.

It uses the properties of boiling water.

The connection is evenly poured with hot water.

Boiling water ensures the connection of the connection at all points.

You should take care of safety and put on protective gloves.

Having done the operation, the bolts are easily dismantled, and the braking cylinder is removed.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments