The GRM abbreviation is deciphered as a gas distribution mechanism. The belt of the gas distribution mechanism acts as a binder element between the crankshaft and the distribution shaft. Replacing the timing belt is strictly regulated by the car manufacturer. On time, the unnoticed timing belt is able to deliver a lot of trouble and significantly increase the cost of the car owner.

Content

- What does the timing belt look like

- Where is the timing belt

- Timing belt marks, why need

- Roller belt timber, why need

- Tension belt timing like check

- Causes of timing belt

- Tools assistants to replace the timing belt

- Replacing the timing belt, work stages

- Replacing the roller timber

- Professional timetables for leaving the timing belt

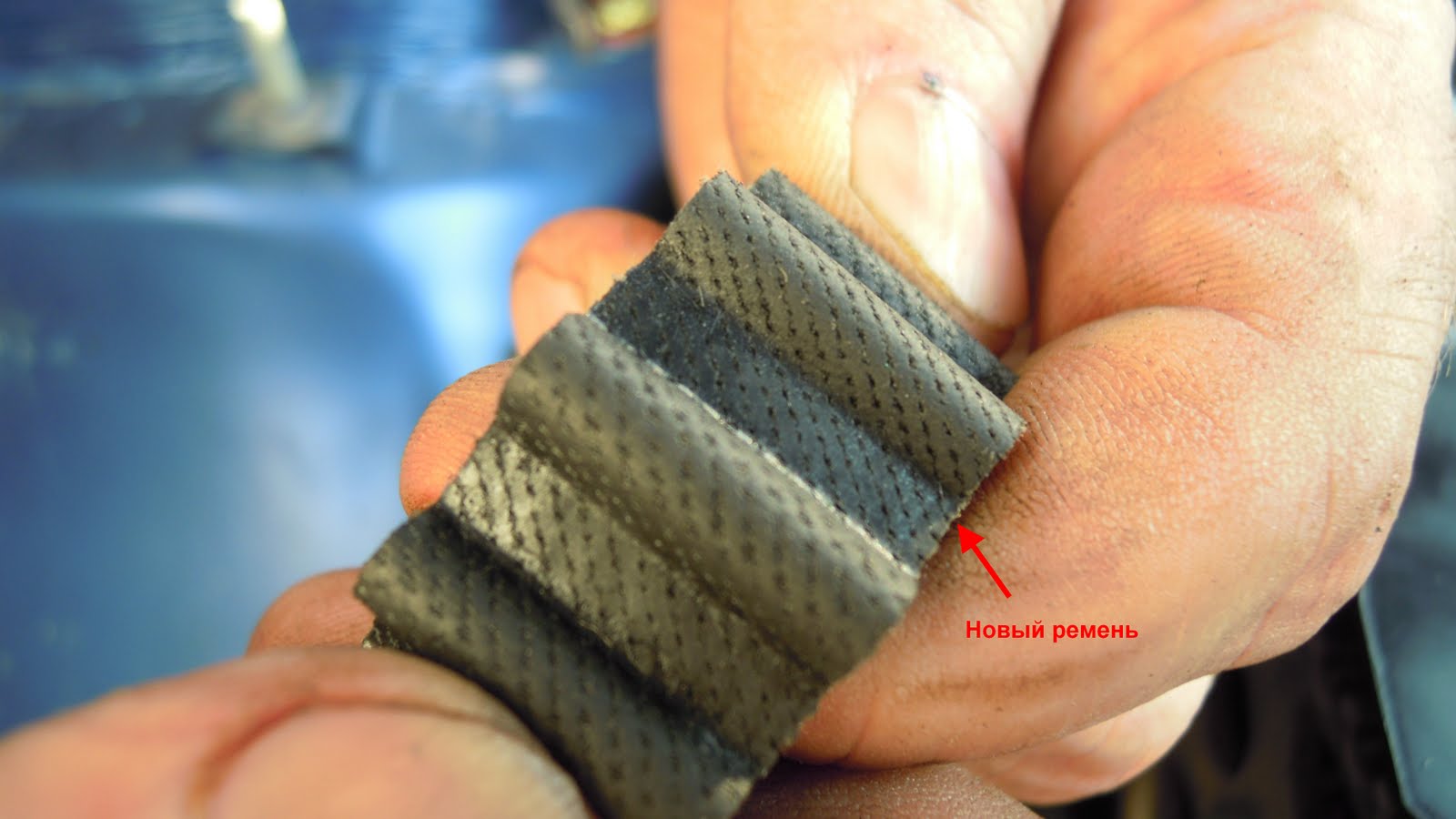

What does the timing belt look like

The belt of the gas distribution mechanism looks like a closed rubber ring, a certain diameter, with teeth on the inside.

The belt is made of rubber or other synthetic materials, due to this, it practically does not make noise, not fully susceptible to corrosion and is part of a complex, single design.

The materials from which the belt of the gas distribution mechanism is made are very stringent requirements. Since it is regularly exposed to high temperatures. The material from which the timing belt is manufactured must maintain its technical characteristics in the temperature range from -50 to 120 degrees.

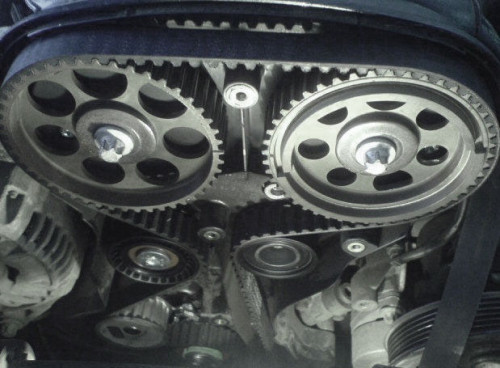

Where is the timing belt

The timing belt is in front of the engine and is hidden directly under the casing of the gas distribution mechanism.

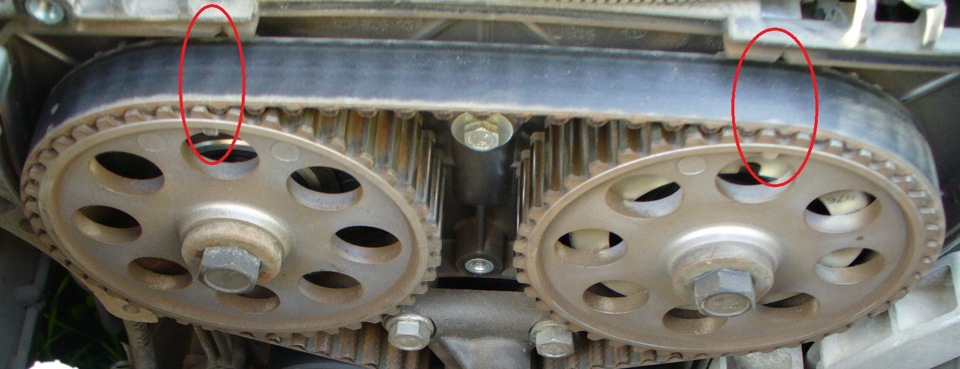

Timing belt marks, why need

When producing a replacement or work related to the removal of the belt of the gas distribution mechanism. First of all, a distribution and crankshaft should be set on special tags.

After that, no turns are allowed, since otherwise the pistons can "meet" with valves. Tags serve as a guideline, in which position should be the crankshaft and distribution shaft, for normal and high-quality engine operation of the car.

Roller belt timber, why need

The tension roller of the gas distribution mechanism is designed to adjust the tension of the timing strap itself. It is a spring-loaded device, which is made on the basis of the bearing. In addition to the tension function, the roller also performs the role of a stabilizer, not allowing the oscillations of the timing belt, as a result of which it can jump or jump.

The roller tension of the timing belt is consumable. As a rule, it changes in conjunction with the belt. In some types of internal combustion engines, several similar rollers are used.

Tension belt timing like check

Checking the belt tension of the gas distribution mechanisms is performed in 3 different cases:

- Replacing the timing belt;

- After carrying out work related to the removal of the timing belt;

- Periodically, the entire period of operation of the car.

Interesting! Read more about checking the timing belt tension in the article "Timing belt, timing belt tension and how to eliminate problems".

In essence, you can use two different ways to check the timing belt tension:

- Method first. At the longest area of \u200b\u200bthe gas distributor belt, try to unscrew the belt using 2 fingers. A well-stretched belt will hardly be rotated at 70-90 degrees.

- The method of the second. In this method, you will need a caliper and manual spring scales. It is necessary to hook scales with a crochet for the belt of the gas distribution mechanism and pull them. It is necessary to pull until the value on the scales reach the value of 10 kilograms. After that, it is necessary to measure the caliper deflection of the timing belt from its normal position. The value at a good belt tension is 5.5 millimeters.

When the belt is tensioning, it should be remembered that it is not allowed both weak and strong belt stretch.

Negative effects with a weak tension of the belt of the gas distribution mechanism:

- Torn timber belt;

- Valve bend.

Negative consequences with a strong tension of the belt of the gas distribution mechanism:

- Version belt wear is intensified;

- Expanded wear of the rollers.

The pledge of durable work as a timing belt and the entire gas distribution mechanism is the correct tension of the strap itself.

Causes of timing belt

The scope of the belt of the gas distribution mechanism is able to deliver a lot of trouble to the car owner.

Let's try to figure out for what reasons there is a rupture of the timing belt:

- Irregular tension of the timing belt;

- Belt wear timing;

- Hit dirt, sand and oil on the timing belt.

Tools assistants to replace the timing belt

Replacing the belt of the gas distribution mechanism occur with the following tools:

- Set of standard automotive keys;

- Special key for tension roller timber timing;

- Manual spring scales.

Replacing the timing belt, work stages

The replacement of the belt of the gas distribution mechanism should be performed only by those people who have the necessary knowledge and skills, as well as confident in their own forces. With incorrect installation and belt tension, the likelihood is extremely high that the car owner will incur additional financial costs. Which, as a rule, they are many more than the amount for replacing the timing belt in the auto repair shop.

Replacing the timing belt occurs in the following sequence:

- Open the car hood;

- Remove the timing belt protection;

- For a bolt, which is directly attached pulley. Turn the strap of the gas distributor in such a way that the cylinder piston number 1 stood in the NTC (upper dead point) when compression tact. The indicator serves as labels on the timing cover and pulley.

- Turning the pulleys into the required position, you must fix them with screwdrivers. To do this, insert it between the flywheel teeth in the clutch crankcase.

- Remove the pulley of the generator. To make it necessary to unscrew the fastening bolt.

- After that you need to loosen the tension roller as much as possible.

- Now you can remove the old belt and install a new one.

- We collect everything in the reverse order and check the tension of the timing belt.

Replacing the roller timber

The replacement of the TRP Tensioner is made strictly according to the list of regulatory work of the car manufacturer.

The timing roller, is made on the basis of the bearing. Like any bearing, the roller of the gas distributor is not eternal and periodically requires replacement. As a rule, this is happening together with the replacement of the belt of the gas distribution mechanism.

It is possible to determine the correctness of the timing roller in the following indicators:

- Rotation of roller smooth and stable (without bounce and outsiders);

- Lack of backlash in the video.

Professional timetables for leaving the timing belt

- The belt and rollers of the gas distribution mechanism should be changed strictly in accordance with the list of regulatory work.

- At each replacement of the gas distributor belt, it is necessary to carefully examine all rollers for the presence of backlays and snacks.

- You should not operate a car with a damaged or incorrectly strained timing belt.

- A squeal descending when driving under the hood of a car, most likely testifies to the thrust strap timing.

- It is not allowed to enter fuel and lubricants or any other garbage on the belt and timing rollers.

- It is necessary to check the tension of the timing belt every 15 thousand kilometers.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments