Piston rings are unlocked rings planted with a slight gap in the grooves of the pistons. As part of this publication, we consider piston rings: what they happen, their purpose, how to determine the wear of the piston rings, how to replace the piston rings, and, etc.

Content

- Piston rings, where they are installed and for what you need

- Why piston rings lose their elasticity

- Why measure compression in cylinders, as compression is associated with piston rings

- How to measure compression in cylinders, in detail

- New piston rings, to pay attention to when buying

- Tools, fixtures, consumables for replacing piston rings

- How to disassemble the engine to replace piston rings, step by step

- How to check rings and pistons

- How to install new rings, step by step

- Correctioning work (thermal glow) after installing piston rings

- Frequent errors when working on replacing piston rings

- As on Aliexpress to find and order new piston rings and other auto parts at a table price and free shipping

Piston rings, where they are installed and for what you need

For purpose, these details are divided into oilmaging and compression.

Compression rings are designed to prevent hot gases from the combustion chamber in Carter. The diameter of the compression ring is slightly larger than the piston diameter, because the rings are made not solid and with a cut, which is also called the ring lock.

Masonry rings do not let the oil from the crankcase in the combustion chamber, removing the remains of the oil from the cylinder walls. These rings are installed on the piston slightly below compression. Unlike them, the oil slimming rings have end-to-end slots.

Main material that uses manufacturers for the manufacture of rings - cast iron. The structure of this metal allows it to effectively hold the oil, preventing the detail at the same time. No less often used derived from conventional carpet cast iron, the so-called plastic cast iron, which, having all the advantages of this metal, is more elastic. This property significantly facilitates the installation of a plastic cast iron rings.

Piston rings made of stainless steel are an improved version of cast-iron chrome rings. The stainless steel is alloy, which includes a rather large percentage of chromium. Rings made from this material have properties similar to chrome plated cast iron counterparts. The stainless steel is well opposed to high temperatures - it is significantly superior to the cast iron.

In order to increase the service life of the piston rings, and improve their "acquisitions", molybdenum began to use in production. This metal has most chromium characteristics, and under certain conditions is wears much less. Gradually, the molybdenum coating rings were suppressed by the details of the cast iron and stainless steel, as they are reliable, durable, and are developed well

Why piston rings lose their elasticity

In order to ensure the maximum density of fitting the outer part of the piston to the cylinder walls, the piston ring must be quite elastic, and, on the other hand, do not have too much pressure on the cylinder mirror in order not to destroy the working surface.

Aluminum piston alloy when heated expands twice as large as the cast iron cylinder sleeve. Therefore, the piston diameter is always a bit less than the diameter of the cylinder - to compensate for thermal expansion. If one of the piston rings loses its elasticity, and begins to lay down in the groove, it leads to a loss of tightness in compressing a combustible mixture.

Under the concept of "lounge" means the position of the piston ring, when it loses its elasticity, and takes off in the ring groove of the piston. At the same time, not burnt remains of gasoline and oil under the influence of high temperature, tightly cement the ring in the groove, and it no longer performs its functions.

Piston rings can lose elasticity and lay in grooves for the following reasons:

• If the placed below is compression, the oil surcharge ring begins to skip the oil portion, it begins to accumulate in ring grooves, gradually turning into a cementing mixture fixing the compression ring in the groove.

• In the case when an overly rich mixture of fuel is supplied to the chamber, it does not completely burn, the fuel residues also fall into the grooves and enhance the effect of the occurrence.

• When the car engine does not work for a long time (3-5 years or more), then compressed and fixed in one position ring inevitably lose their elasticity. To avoid this, the engine must be launched at least once a few months for 15-20 minutes.

Why measure compression in cylinders, as compression is associated with piston rings

Most often, the rings run in the groove not completely, but partly. If the compression ring is functioning normally, the effect of gases is distributed evenly throughout its surface. When part of the ring sticks in the groove, and the ring begins to squeeze unevenly, with time so-called fatigue microcracks begin to appear, as a result of which the engine compression is much deteriorated.

The word "compression" in the literal translation from Latin means "compression". If you leave all the complex physical terms and formulas aside, we are talking about pressure inside the combustion chamber at the time of reaching the upper dead point. The higher the compression, the stronger the fuel mixture is compressed, and the gases do not break into the crankcase. Accordingly, the engine efficiency is at the proper level.

When the compression level corresponds to the manufacturer's indicators, the engine will work in optimal mode with a minimum amount of exhaust gases. Compression is measured in Pascals, kilograms per centimeter, but most often in the atmosphere.

How to measure compression in cylinders, in detail

If you are going to measure the compression in the engine of your car, you must comply with some simple rules:

• The engine must be heated.

• Fuel supply is disabled (you can turn off the fuel pump, nozzles, or use any other method).

• You need to unscrew all the candles (selective removal of candles, as a service station, is unacceptable, since in this case the resistance increases and revolutions are reduced).

• The battery must be fully charged.

Compression can be measured both with closed and open throttle. In this case, each option makes it possible to get your results and identify certain malfunctions. For example, with a closed flap to the cylinders, there will be some air, which will reduce the compression (it will be approximately 0.6-0.8 MPa). Air leakage in this case is completely insignificant and approximately equal to its entry into the cylinder. As a result - the compression begins to "react" very sensitively even on the most minor leaks.

When measuring compression, a slightly different pattern is a slightly different pattern. A significant amount of air that enters the cylinder, of course, contributes to an increase in leaks.

However, they are significantly less than the number of incoming air. Therefore, compression drops slightly (up to 0.8-0.9). Thus, the compression with an open valve is best suited for the detection of significant damage in the engine, for example: damage to the pistons, rings, burned valves, damage to the cylinder mirror.

Regardless of which of the two ways described in the methods, compression is checked, in the measurement process, it is necessary to consider exactly how the indicators of the pressure gauge are changed. For example, if the first time indicators are 0.3-0.4 and during subsequent clocks increase sharply, it may indicate possible wear of piston rings.

than check engine compression

The most popular device for measuring the engine compression is a compressometer. Its design is quite simple: a pressure gauge for measuring compression, flexible hose, and an inlet valve for air, which is inserted into the candle hole.

Famous Western manufacturers produce "cheap" embodiments of compressometers equipped with a whole arsenal of adapters, with which you can measure compression on cars of any brands.

Very quickly and accurately measure the compression of the engine can also be using a modern tester motor.

In fact, this device records not the pressure itself, but the amplitude of electricity, which is used by the starter. It's simple: the more pressure, the more difficult the starter to work, therefore, more energy is consumed. With this instrument, you can measure compression in all cylinders at the same time, without twisting the candles, which is very convenient when working with multi-cylinder engines.

The main disadvantage of the tester motor is that the measurement results are displayed relative - for example, as a percentage of the cylinder, which works better. Only the most expensive models Motor Testers show the amount of compression in each cylinder, and then this is possible only if there are a large amount of data on the engine model, which is compared with the tester indicators.

what compression is considered normal

With a fully suitable engine, the indicators will be the following:

Open valve: 1.0-1.2 MPa.

Closed valve: 0.6-0.8 MPa.

When measuring compression, the main thing is to remember that the results obtained are relative, and this means that it is not necessary to repel from specific numbers, but on the difference of compression in different cylinders.

New piston rings, to pay attention to when buying

Another one and a half-days of the decade ago, good piston rings were somewhat problematic. Today, the range of these parts can be said, it shrins - it remains only to choose correctly. The quality and reliability of the piston rings and other parts of the cylinder-piston group are radically affect the service life of the engine, so that their choice should be approached seriously.

choose piston rings, advice pro

• Manufacturers produce rings of several sizes, including 1-2 repairs. First of all, you need to pay attention to the manufacturing material. One of the best is cast iron.

• Experienced motorists and locksmith, choosing rings, touch the presence of chamfer on the outside of the part. Her presence talks about the good quality of the goods - the fake chamfer do not have.

• Another noticeable difference in high-quality product is light and rounded ends.

• If the ring is covered with chrome, it has a matte tint, not a chrome ring creates a bright steel shine.

• To guarantee not to buy a fake, specialists use the micrometer by checking the nominal and repair dimensions.

• Be sure to pay attention to the marking of the rings. Factory labels are put strictly in certain places, and on counterfeit tags can be in an arbitrary place, as they fell.

• Rings must be in branded packaging three pieces. The packaging indicates the engine model, set number and rings size. A complete set of rings contains the number of packages (3 pcs.), Corresponding to the number of engine cylinders for which it is intended.

Tools, fixtures, consumables for replacing piston rings

Before you start, you need to prepare everything you need:

• A set of keys.

• Set of heads, ratchet.

• Dynamometric key.

• Crimping for piston rings.

• Set of hex keys.

• Actually, a set of piston rings.

How to disassemble the engine to replace piston rings, step by step

• We drain the exhaust oil. After replacing the rings, it should be replaced with fresh.

• Weaken the fuel reception tube.

• Remove the valve cover and exhibit the motor on the labels.

• Remove the camshaft star (in front-wheel drive cars - unscrew the belt pulley fastening bolt, remove the timing belt together with the pulley).

• Weaken the tensioner, remove the chain and the star from the camshaft.

• We dismantle rocker with springs.

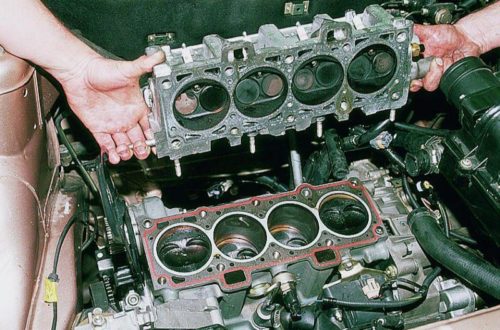

• We unscrew and remove the block head, pre-disconnecting the collector.

• Remove the pallet and oil pump.

• Remove the connecting rods. The connecting rods are pushing up so that they can be removed with the piston.

How to check rings and pistons

All rings are removed and tested only in the "native" cylinder. To confuse anything, the rings should be decomposed in a certain order. When checking the rings, the gap between the outer diameter and the cylinder mirror should be not more than 1 mm.

The heat gap rings is best measured in the upper part of the block, as the smallest wear is in this place. Clearance is checked in special calibers. The normal thermal gap in the rings is from 0.25 to 0.45 mm. - Measurements are made by probe.

The piston diameter is measured only at its lower part (skirt). Measurements are carried out by micrometer. The obtained indicators are compared with the table of permissible values. Also check the gap between the rings and the ring itself. If the indicators exceed the permissible, the piston is subject to replacement.

How to install new rings, step by step

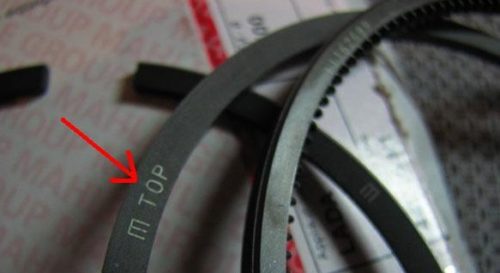

If the product is branded, it has a special labeling in the form of the "torus" inscription, which means "top". This side is installed to the combustion chamber or the top of the piston.

If there is no inscription, there must be a duct along the entire diameter of the ring. The ring is set by a flowing down.

Piston rings can be installed in two ways. The first is more practical and safe, the second is applied by professionals or full newcomers. Both methods are quite suitable for replacing the rings on their own.

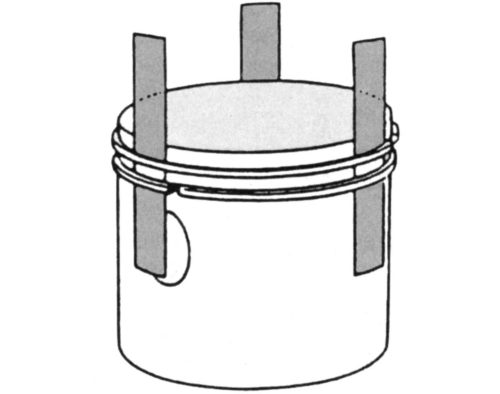

Cut several strips of tin thick up to 0.5 mm. Several pieces of tin kept tightly pressed to the piston, the ring is dressed up to the level of the groove. Then this improvised mandrel is cleaned, and the ring sits in place. The way is simple, proven and reliable.

Another method will require any experience. The essence lies in the fact that the ring with the hands is divorced to the desired diameter, after which insert into the groove. The minus of this method is that inexperienced newcomers break a lot of rings when trying to install them.

Correctioning work (thermal glow) after installing piston rings

Once the rings are set, the slots need to be installed at least 120 degrees from each other so that the gases do not fall into the crankcase.

The first ring holds up to 75% compression, the second only 20%. If the gaps are divorced correctly, then even if the gas is breaking through the first ring, its second is guaranteed.

Frequent errors when working on replacing piston rings

It is impossible to install new rings in worn cylinders, as it does not give any result, since the worn sleeve has the form of an ellipse. At high speed rings in a worn cylinder can simply burst, damaging the mirror even more.

A gross error - setting the rings with gaps opposite each other. In this case, the gases overheat one side of the piston, it deforms, burns, and the piston fails.

As on Aliexpress to find and order new piston rings and other auto parts at a table price and free shipping

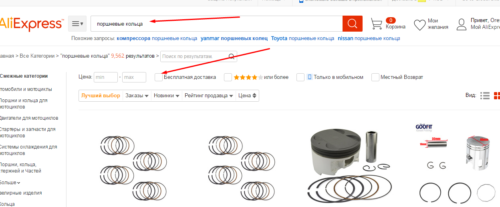

Aliexpress- The world-famous huge shopping area with a huge selection of various goods in very attractive prices. You can buy everything literally all, including auto parts.

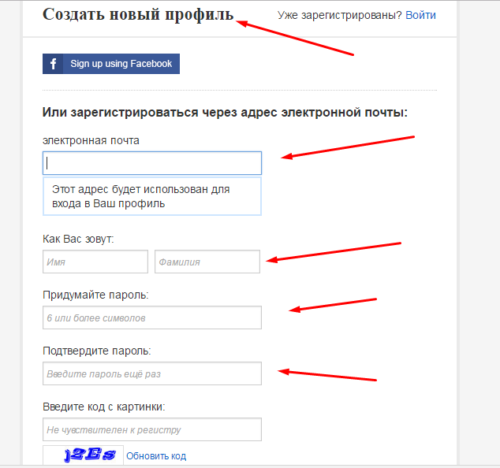

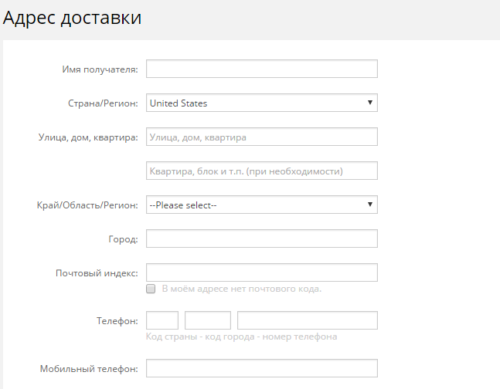

In order to get the opportunity to buy on aliexpressYou must pass the registration process. All data is filled with Latin.

After that, go to your freshly pricked profile, and indicate your address where the purchased goods will be delivered:

Now you can search for the desired product, for example, piston rings. To search for goods with free shipping, celebrate the checkbox "Free shipping" checkbox.

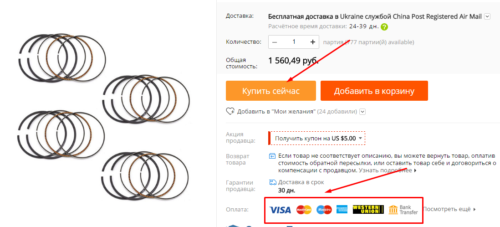

We choose the right product, click the "Buy Now" button, and we pay for any convenient way on the portal.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

- Corrosion of car thresholds, film on car thresholds, how to stick a film on the thresholds of the car

- Gas or oil shock absorbers, which shock absorbers to choose, the top 10 of the best manufacturers of shock absorbers

- Speedometer machine, why speedometer does not work, repair speedometer

- Electric wiring trailer. Volume car trailer wiring. Connecting electrical wiring trailer

- Electronic gas pedal, operation of electronic pedal gas, malfunction of electronic pedal gas, repair of electronic gas pedal

- Tachometer on auto, tachometer does not work, causes a tachometer breakdown, make repair with your own hands

- A catalyst is scored, signs of a scored catalyst, how to check the catalyst, which can lead to the operation of a faulty catalyst

- Correct car putty, liquid putty for cars, how to choose a putty for a car, putting a car with your own hands

Comments