In the same way, human skin care needs to leave the car body surface. To preserve the original shine and protect the surface of the paint coating from the effects of ultraviolet and aggressive components present in the environment, it is recommended to periodically perform protective polishing.

To extend the life of the car, it will be enough to perform a polishing 2-3 times a year. More accurately determine the timing of the procedure, we can consider the intensity of operation, storage conditions, the presence of factors that have a negative impact on the surface of the paint layer.

Content

Types of polishing body

A car paint coating by age up to 3 years old is considered fresh, it in most cases needs a purely cosmetics procedure, i.e. protective polishing. This is also required for fresh-cutting machines.

For cars, which had to survive numerous "stressful situations" may require restorative polishing. The reason is that with long-term operation on the surface of the paint layer, numerous small defects appear: scratches, scuffing, drawing. It seems to be a trifle, but the shine is lost and once the luxurious surface becomes dim and unattractive.

The process of restoration work is more complicated, the use of abrasive substances will need. In the process of their use, a certain part of a parallery layer is removed. Naturally, such a procedure requires certain skills and special caution. Moreover, the abrasive polishing can be performed not more than 2-3 times for the entire period of operation of the car.

Experienced drivers recommend contacting restoration work in the car service, and to experienced and proven masters.

But if the usual polishing of the car is required, the price of which is at least 1000 rubles, it makes sense to learn how to perform this simple procedure independently.

Structure of paintwork, how to determine which body needs polishing

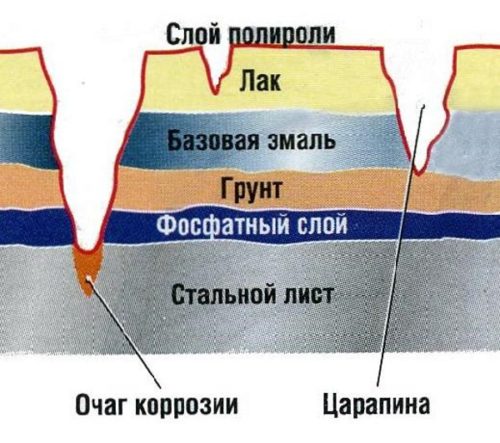

Paintwork consists of:

- phosphate film carrying chemical protection

- primer layer

- paints and varnish shown in several layers

But all of them, just like human skin, are not able to completely block access to metal parts, i.e. Their structure has pores through which moisture is delivered containing salt, acids, other dangerous reagents. At the same time, destructive chemical reactions - the phenomenon is inevitable.

The first signs of the beginning of the corrosion process are small specks-freckles, then we can expect the appearance of rusty spots. These processes begin especially quickly during the operation of the car in urban conditions.

Avoid negative phenomena helps applying a special substance - polyrol. It can fill all micropores and cracks on the surface, isolate the deeper layers of the paint coating, the surface of the body as a result becomes brilliant as new.

Unfortunately, over time, the protective layer is washed away, it is usually capable of listening to 5-6 months, depending on:

- from the quality of the polyroli used

- frequencies of car miles

- the presence of aggressive reagents in the environment

Note that there are absolutely all cars in care, even very new ones. The quality of the polishing layer can be judged by the type of body: it should have a shining surface, such a capable and rays of ultraviolet reflect and protect against water.

In order not to miss the time when it should be done by polishing work, it is possible to blame the surface during the sink. If the protective layer works still, the water will be collected by large drops, like mercury. If the water wets the larger area, i.e. spreads - the time has come when the polyrolol should be applied.

You can buy polyrolol in any store engaged in the implementation of auto parts and maintenance of motor vehicles. Naturally, when examining a wide range, the question will arise: what product and from which manufacturer to give preference.

Types of polyterols for the car

In order not to make a mistake in the choice, first learn what the polyroli is in composition.

Firstly, they are separated by the form of the foundation, it can be:

- synthetic (polymer)

- natural (wax)

Silicone or wax formulations have low cost, and the result obtained after their use is short-lived. Although it is easy to give shine and chic to the body with their help. Such means are often used if the car is prepared for sale.

The polymer compositions have a higher cost, the process of applying is more complex, but the result is more durable and qualitatively.

If the work is performed for yourself, and the result should be saved as long as possible, it is necessary to choose the polyroli expensive, high-quality, synthetic.

The same recommendation also concerns other consumables:

- cleaners

- degreasers

- sleeps

As for other qualities, the polyteroli for the car body is divided into the following varieties.

color enriched

Separate them should be strictly in accordance with the color of the vehicle covering.

Among the advantages should be noted the ability:

- restore initial color

- masking chips

- great filling all cracks and scratches tracks

The disadvantage is low stability, requires updating every 2-3 weeks.

with protective effect

In its composition, such masts contain Uretan and Teflon, which differ in the ability to react with the surface layer of varnishes and paints. As a result, the level of protection of the coating itself becomes higher.

A qualitative means under the condition of proper application can maintain its qualities for 2-3 months. To get a higher effect practicing the use of protective polyroli in combination with other care products.

Since it becomes possible to accelerate the corrosion processes to accelerate the surface of the metal, it is not recommended to apply them to cracks and chips, it will take pre-processing of defective surfaces with special protective agents.

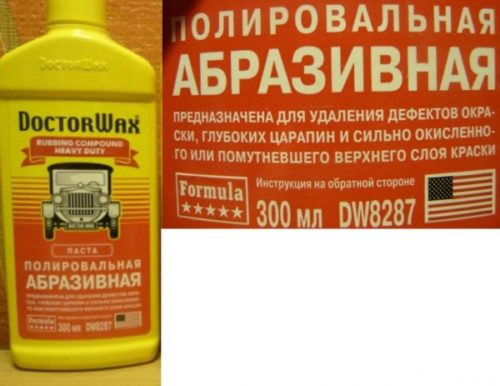

abrasive action

Referring to the use of similar products should be careful, because as a result of their use, partial removal of the upper LCP layer occurs. A positive moment is thus the surface is getting rid of minor scratches and cracks, a partial restoration of color occurs.

It should also be aware that such polyters vary according to the degree of abrasiveness, their frequent use may cause strong thinning of the paint layer and the acquisition of mattness.

wax

Used exclusively for the purposes of imparting a shine surfaces. These materials may have a natural or synthetic origin, they are colorless, have a fairly thick consistency.

Due to the dense texture, apply such materials difficult. High protective properties wax materials do not differ.

paste for polishing

The rational all use them when processing old, worn LCPs. It is also recommended that the use of car bodyworks operated in difficult weather conditions or in a zone with an increased content of aggressive impurities in the environment.

Pastes have a thick texture, applied a thicker layer than other polishing agents. As the most popular tool, you can mark top sealers paste.

express paste

Allowed to obtain effective polishing very quickly, with minimal effort. To guide the amazing gloss, only a few minutes will be required.

In this case, the pastes are not distinguished by high protective qualities, the result obtained during their use is short-lived.

Detailed instructions for applying polishing means is attached to the product when it acquisitions, in the form of a separate instruction or label inscription.

Polyrol plastics

Is it worth saying that the self-respecting driver does not sit behind the wheel of a car with a dirty salon dusty control panel. But to ensure order and cleanliness, as well as to give the shine to all plastic surfaces, it is recommended to use a special means - a polyrol for plastic.

If there are strong contaminants on plastic or vinyl parts, it is recommended to use universal cleaners, such as Turtle Wax Trim Clean. Cleaning from dirt should be carried out before, before proceeding with polishing.

With this, you can also clear all the parts of the body finish on which the paint is not applied:

- bumper

- moldings

- shirts mirrors

The same cleaner will help remove the remains of old wax polishing.

If we talk about the properties of the polyteroli for plastic, it should provide:

- cleansing from minor pollution

- giving an antistatic effect

- creating a dust and dirt-repellent layer

- pressing the surface of the details of a well-groomed view for some time

- restoration of sections with scratches, scratches, traces of influence of chemical reagents

Present in the means of coloring pigments will help ensure the disguise of small and medium defects on plastic, both inside and on the body surface: on bumpers and moldings, for different plastic shades, poly rays with pigments of the corresponding shades are used.

But if necessary, you can use the means in which the pigment is not included, i.e. colorless.

Note that there are poly rays that give the surfaces of the shine and, on the contrary, matting it, sometimes it is very convenient. For example, the matted surface of the front panel will not discard the glare on the glass, i.e. The moment of impairment is excluded.

If desired, it is possible to purchase a polyrolol giving not only resistant shine, but also a pleasant aroma of a plastic surface.

Polyrol for glass

Like other materials, glass details present in the design of the car need periodic cleaning and processing by caring means. Applying special means you can provide high-quality visibility through the windshield of the car for a long time, naturally, it will determine the movement to a certain extent.

High-quality glass polishing:

- rare out of the need for systematic wraths, therefore, the amount of wiping from the effects of a sponge will decrease

- provide some protection against ultraviolet rays

- eliminate the harmful effects of acid component of natural precipitation, aggressive funds present in shampoos used on car wash

- protects from dust and sand falling on glass

Neutralizes the harm caused by moving janitars, especially worn out

The correctly selected and applied polishing for glasses can serve as a kind of insurance.

Polyrols for glass are two types:

- teflon

- wax

Experts recommend to give preference to teflon products - they serve for a longer time and are not washed off with water.

Polishing of glasses can be used protective or abrasive. The protective assumes the deposition of a polyrol without special training, after elementary glass cleaning, and abrasive application requires an additional procedure - grinding. Abrasive grinding method provides a more pronounced and long effect.

You can apply the glass polyrolol manually or using a grinding machine (or a drill with a special nozzle).

The most popular car enthusiasts is brands products:

- DOCTOR WAX.

- Sonax

- Turtle Wax

Polyrol from scratching

Both deep and minor scratches can largely spoil the appearance of the car, as well as to influence its service life. Therefore, it is recommended to eliminate them as soon as possible. Minor damage can be removed by independently, using a special auto-polyrolol, which will allow you to quickly cope with scratches of various kinds that appeared on the body.

But before proceeding to eliminate damage, it is necessary to carefully analyze how serious they are, to explore:

But before proceeding to eliminate damage, it is necessary to carefully analyze how serious they are, to explore:

- does the paint layer under varnish are damaged

- are there defects on the primer layer

- lee opened metal

You can estimate the depth of damage to visually, it will be more correct to use a magnifying glass, it will allow you to thoroughly explore the edges. It is recommended to deal with the definition of damage to the degree of damage during the bright daylight, with artificial lighting, it is almost impossible to obtain an accurate estimate.

If damage is sufficiently serious, then it is best to seek help from car service crafts.

If there are minor scratches, you can use:

- funds from chips and scratches

- special pencil

- auto Polyaroli, Providing Elimination Scratches

With minor defects, it is permissible to use polyrol in the form of an aerosol, the cost of it has a low, it will be able to eliminate small scratches and grids of cracks. Such a means covers the surface with a thin layer, the disadvantage of it is high spreadability, which significantly increases the consumption of the material. Processing with liquid means has to be repeated more often, because They form a rather thin layer.

Deep downward damage will require the use of composition with abrasive substances. Such funds are sold in the form of a paste, it allows you to create a thick layer, which will perfectly fill all chips and scratches. But at the same time will have to make significant efforts for the arrangement and spend more time.

Polyrol Liquid glass for cars

The inventors of this type of car polishes - Japanese produce liquid glass to care for the paintwork began relatively recently. Protected waterglass layer surface become invulnerable to mechanical damage to the lungs, they are less polluted, they do not affect any moisture or air.

The operating principle of polishing liquid glass is the same as that of the above-mentioned means, but shine after application is obtained simply amazing, it provides a sufficiently strong invisible film. When applying the corrected almost all the surface defects is reduced LCP structure itself, the coating is capable to serve more than six months.

Since the film has a tendency to lose strength from chemical detergent compositions, the washing machine is best clean water without the use of shampoos, rags, brushes.

We should not forget that the glass surface is characterized by high ductility, with a sharp impact film may crack. The same may occur at lower temperatures.

Apply water glass should be strictly thresholds and instructions, only in this case we can expect a long service life. The cost of funds - it is quite acceptable, but work on its application is better to entrust the professionals - given the propensity for rapid crystallization, the complexity of the process, the requirements for the availability of skills of the performer.

Subject to the fulfillment of all requirements of car will please its owner amazing shine and well-groomed view for 6-8 months.

Polishing a car with his hands, step by step

polishing process consists of three stages:

- body preparation

- reconstruction

- applying a layer of protective agent

Initially should conduct cleaning surfaces of dirt, insects traces bitumen stains, remnants of the old polishes. For stubborn dirt, is recommended for further purification using a special clay. After moistening cleaner for cleaning portions requiring applied clay, with little effort cleaning process is performed to obtain a smooth surface.

clay residues are removed with a dry cloth. If necessary, the procedure can be repeated. Clearing only selected areas are subjected after processing them repeatedly degreased.

After washing the car well dry.

Next, you need to treat the body with a degreasing composition. For application use a soft cloth.

Next, go to the application of the means. Capacity with polyrolla is recommended to shake well. The composition should be applied into small areas, a maximum of 0.5 m x 0.5 m., Point, strips, or making circular movements with a soft foam sponge.

After waiting a couple of minutes, we give the polyteroli to dry, with the help of special wipes for polishing, we process the surface to obtain a uniform shiny film.

It is not recommended to give a substance to completely dry - the receipt of a uniform layer will require great effort, to achieve uniformity will be harder.

Information on the exact number of polyteroli and exposure time will be prompted by the process itself, after processing the first section, these issues will be solved by themselves.

Conditionally divide the surface of the body to the plots, gradually process each of them.

We do not forget that for a complete shrinkage of polishing makeup requires approximately 24 hours. But this does not mean that the car should be kept in the garage. It is desirable not to travel the first two hours after processing.

In order for your work to give expected results, it will not be superfluous with useful tips from experienced motorists.

Useful advice

It is best to perform polishing work in the room, while not to choose a very hot or very cold day - high temperatures will lead to an accelerated drying of the composition, at a low temperature - the composition will be filled too slowly, the distribution process will complicate.

During work, you should not allow large grains to fall on LCP and even dust - they can spoil all the work, which can lead to the need to perform rehabilitation polishing.

Perform a missing best with special napkins, the cost of them is not high, 4-5 pieces will need for processing the entire body, the sale of the napkins is carried out by car station shops.

In order not to pollute and damage the moldings, door handles, rubber seals are recommended to be sealing them with a masking ribbon, such as used when painting machines, it may need about 100 meters (2 meters).

When buying carpackers, it is desirable to give preference to the products of one manufacturer. Especially carefully close to this issue if abrasive polishing will be performed.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

- Corrosion of car thresholds, film on car thresholds, how to stick a film on the thresholds of the car

- Gas or oil shock absorbers, which shock absorbers to choose, the top 10 of the best manufacturers of shock absorbers

- Speedometer machine, why speedometer does not work, repair speedometer

- Electric wiring trailer. Volume car trailer wiring. Connecting electrical wiring trailer

- Electronic gas pedal, operation of electronic pedal gas, malfunction of electronic pedal gas, repair of electronic gas pedal

- Tachometer on auto, tachometer does not work, causes a tachometer breakdown, make repair with your own hands

- A catalyst is scored, signs of a scored catalyst, how to check the catalyst, which can lead to the operation of a faulty catalyst

- Correct car putty, liquid putty for cars, how to choose a putty for a car, putting a car with your own hands

Comments